- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

50hz&60hz

-

Welding Area:

-

To depends

-

Dimensions:

-

dia100x300,handle dia56mm

-

Use:

-

plastic welding

-

Weight (KG):

-

1.8 KG

-

Power (kW):

-

1.6

-

Marketing Type:

-

Hot Product

-

Airflow:

-

230L per min

-

Temperature:

-

20-650C

-

Color:

-

green,black, red,blue

-

Power:

-

1600W

-

welder handle:

-

resist 280℃

-

Electronic card:

-

fully sealed

-

Motor:

-

13000rpm

-

filter:

-

even hole, no block

-

Insulation gasket:

-

3M

-

Certificate:

-

CE ROHS

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

HEATFOUNDER

-

Voltage:

-

220V&230V

-

Frequency:

-

50hz&60hz

-

Welding Area:

-

To depends

-

Dimensions:

-

dia100x300,handle dia56mm

-

Use:

-

plastic welding

-

Weight (KG):

-

1.8 KG

-

Power (kW):

-

1.6

-

Marketing Type:

-

Hot Product

-

Airflow:

-

230L per min

-

Temperature:

-

20-650C

-

Color:

-

green,black, red,blue

-

Power:

-

1600W

-

welder handle:

-

resist 280℃

-

Electronic card:

-

fully sealed

-

Motor:

-

13000rpm

-

filter:

-

even hole, no block

-

Insulation gasket:

-

3M

-

Certificate:

-

CE ROHS

Plastic welder 230V 1600W /110V 1600W

Application Weldingof thermoplastic materials as well as single – ply flexible plastic and modified bitumen in the form of boards,tubes profiles, lining membranes, coated materials, films, foams, tiles and sheets.

The following procedures are possible :

Overlap welding ,welding with rod, with tape, butt welding and melt welding. Heating – upfor forming , bending and sealing of thermoplastic semi- finished materials and plastic granules. Dryingof water – damp surfaces. Shrinkingof heat shrink sleeves, films , tapes, solder sleeves, pre formd and moulded parts. Solderingof copper pipes, solder joints and metal foils. Defrosting of frozen water pipes. Activating / Dissolvingof solvent free adhesives and fusion adhesives.

Overlap welding ,welding with rod, with tape, butt welding and melt welding. Heating – upfor forming , bending and sealing of thermoplastic semi- finished materials and plastic granules. Dryingof water – damp surfaces. Shrinkingof heat shrink sleeves, films , tapes, solder sleeves, pre formd and moulded parts. Solderingof copper pipes, solder joints and metal foils. Defrosting of frozen water pipes. Activating / Dissolvingof solvent free adhesives and fusion adhesives.

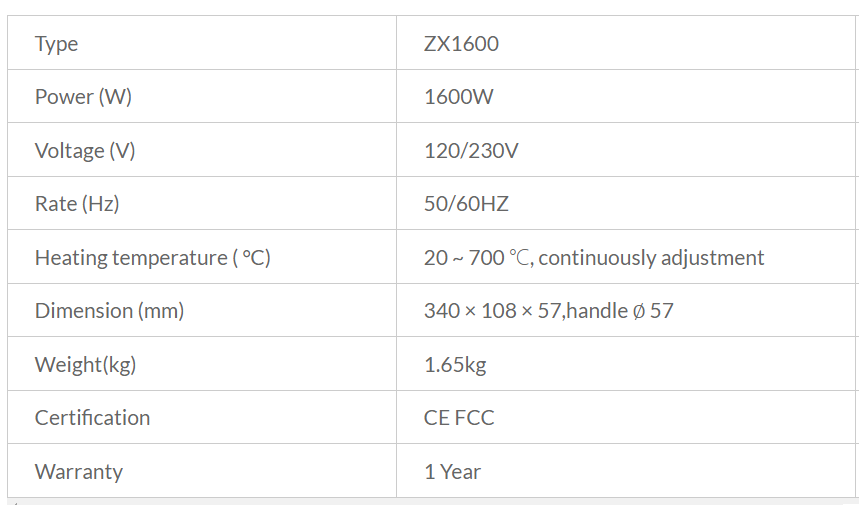

Specification

Products Description

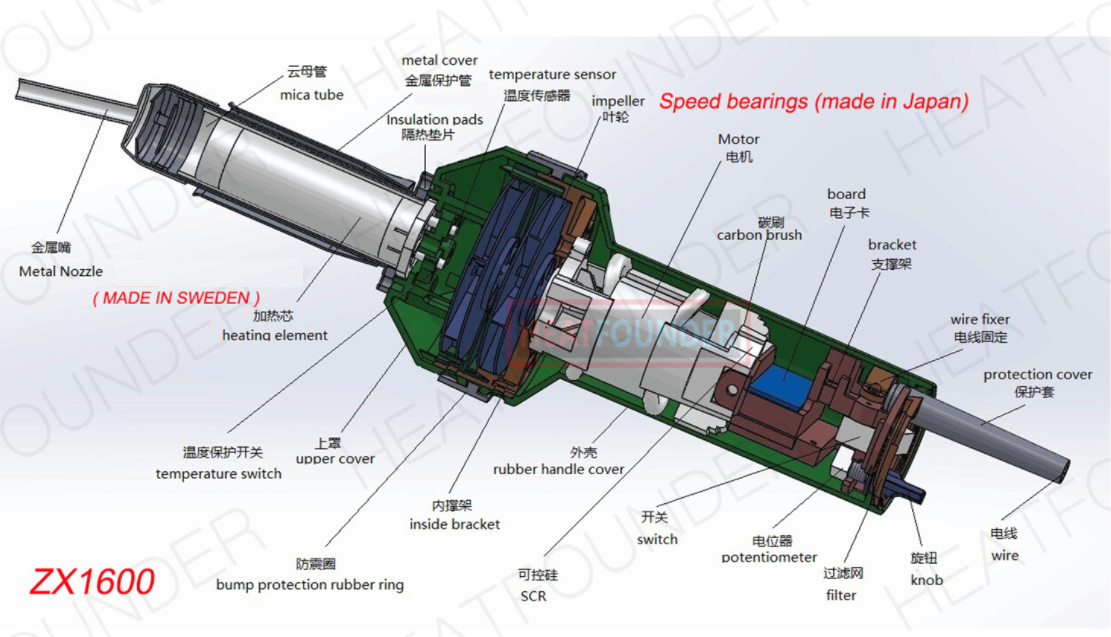

Material for plastic welder:

1. We use photocell to controll temperature inside.

2. Outside of the gun there is temperature switch.

And once the plastic body is above 135 degree,the whole circuit will be cut off.

3.At present,this plastic is one can resist the highest temperature.

It can resist 280 degree.

4. We use high temperature bearing manufactured in Japan.

5.We use Swedish heating wire for ceramic heating element inside the plastic welder.

And ceramic material is also good quality.It can resist high temperature 1650C.

Details Images

Product Advantages

Application

Certificates:

Customers visiting:

Packing & Delivery

Hot Searches