- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

500

-

Weight (KG):

-

650 KG

-

Place of Origin:

-

guangdong

-

Brand Name:

-

MZH

-

Voltage:

-

220

-

Dimension(L*W*H):

-

2100*1700*1800mm

-

Power (kW):

-

5.5 kW

-

Name:

-

liquid detergent production line

-

Usage:

-

shampoo detergent shower gel

-

Capacity:

-

customized

-

Homogenizer:

-

High Shearing Rotor

-

Control:

-

PLC

-

Function:

-

mixing homogenizing

-

Heating method:

-

electric or steam heating

-

Type:

-

Cosmetic Making Machine Homogenizer

-

Speed:

-

0-2880rpm

Quick Details

-

Barrel Volume (L):

-

500

-

Max. Loading Volume (L):

-

500 L

-

Range of Spindle Speed(r.p.m):

-

0 - 63 r.p.m

-

Max. Loading Capacity:

-

500

-

Weight (KG):

-

650 KG

-

Place of Origin:

-

guangdong

-

Brand Name:

-

MZH

-

Voltage:

-

220

-

Dimension(L*W*H):

-

2100*1700*1800mm

-

Power (kW):

-

5.5 kW

-

Name:

-

liquid detergent production line

-

Usage:

-

shampoo detergent shower gel

-

Capacity:

-

customized

-

Homogenizer:

-

High Shearing Rotor

-

Control:

-

PLC

-

Function:

-

mixing homogenizing

-

Heating method:

-

electric or steam heating

-

Type:

-

Cosmetic Making Machine Homogenizer

-

Speed:

-

0-2880rpm

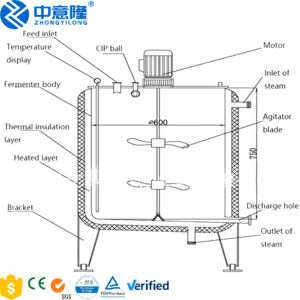

Product Application

500L mixing tank liquid soap making machine,industrial liquid detergent production line

is our latest product research and developed by our company which combined overseas superior emulsifier experience with domestic cosmetic enterprise feedback.

liquid detergent production line

dopts imported stainless steel, scientific homogenizing system, reasonable scraper blending to ensure equivalent homogenizing and make product more smooth, even and bright.

|

Capacity

|

Model

|

Mixing power(kw)

|

Mixing speed

(r/min) |

Homogenizing power(kw)

|

Homogenizing speed(r/min)

|

Heating method

|

|

200L

|

MZH-200

|

0.75

|

0-65

|

2.2-4

|

3000

|

Steam heating or

Electric heating |

|

300L

|

MZH-300

|

0.75

|

0-65

|

2.2-4

|

3000

|

|

|

500L

|

MZH-500

|

2.2

|

0-65

|

5.5-7.5

|

3000

|

|

|

1000L

|

MZH-1000

|

4

|

0-65

|

7.5-11

|

3000

|

|

|

2000L

|

MZH-2000

|

5.5

|

0-53

|

11-15

|

3000

|

|

|

3000L

|

MZH-3000

|

7.5

|

0-53

|

18

|

3000

|

|

|

5000L

|

MZH-5000

|

11

|

0-42

|

22

|

3000

|

|

|

10000L

|

MZH-10000

|

15

|

0-42

|

30

|

3000

|

|

Main Features

liquid detergent production line is mainly suitable for preparation of liquid detergents(such as cleanser essence,shampoo and shower cream etc)

Integrating blending ,dispersing ,heating and cooling etc. functions,the reacting machine is an ideal device for liquid perparation in various factories .

Top Blending power :0.75KW 0-63R/MIN

Bottom Homogenizer power : 2.2KW 0-2880 R/MIN

Bottom: PLC outlet Stainless steel butterfly valve

Cover design Can be moved , open or closed

Function and usage

1.The machine is suitable for the production of various kinds of shampoo, lition, liquod soap and detergent etc. liquid washing products in cosmetic factory.

2.Blending reacting boiler is mainly suitable for preparation of liquid detergents (such as cleanser essence,shampoo,shower gel and liquid soap etc.).

|

Packaging

|

|

|

|

Size

|

2100X1700X1800mm

|

|

|

Weight

|

650KG

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1. Q: Are you factory or trading company?

A: We are the professional manufacture of cosmetic machinery in China more than 10years

2. Q: Where is your location?

A: Company and Showroom located in Guangzhou china, Factory located in Jiangsu and Shanghai Province.

3. Q: Are your engineer be able to serve in oversea?

A: Yes, we have a lot of experience install the machine in oversea.

4. Q: What is your material of your product?

A: adopt with full stainless steel 304-2b and 316L

5. Q: How does your factory do regarding quality control?

A: Two years spare parts,and full-life service of our machinery.

Our Company to customer satisfaction for the development of three goals: product quality, product technology and after-sales service!