- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

More than 5 years

-

Technics:

-

wood plastic composite

-

Place of Origin:

-

Zhejiang,China

-

Model Number:

-

BS-18

-

Brand Name:

-

KELAI DECKING

-

Material:

-

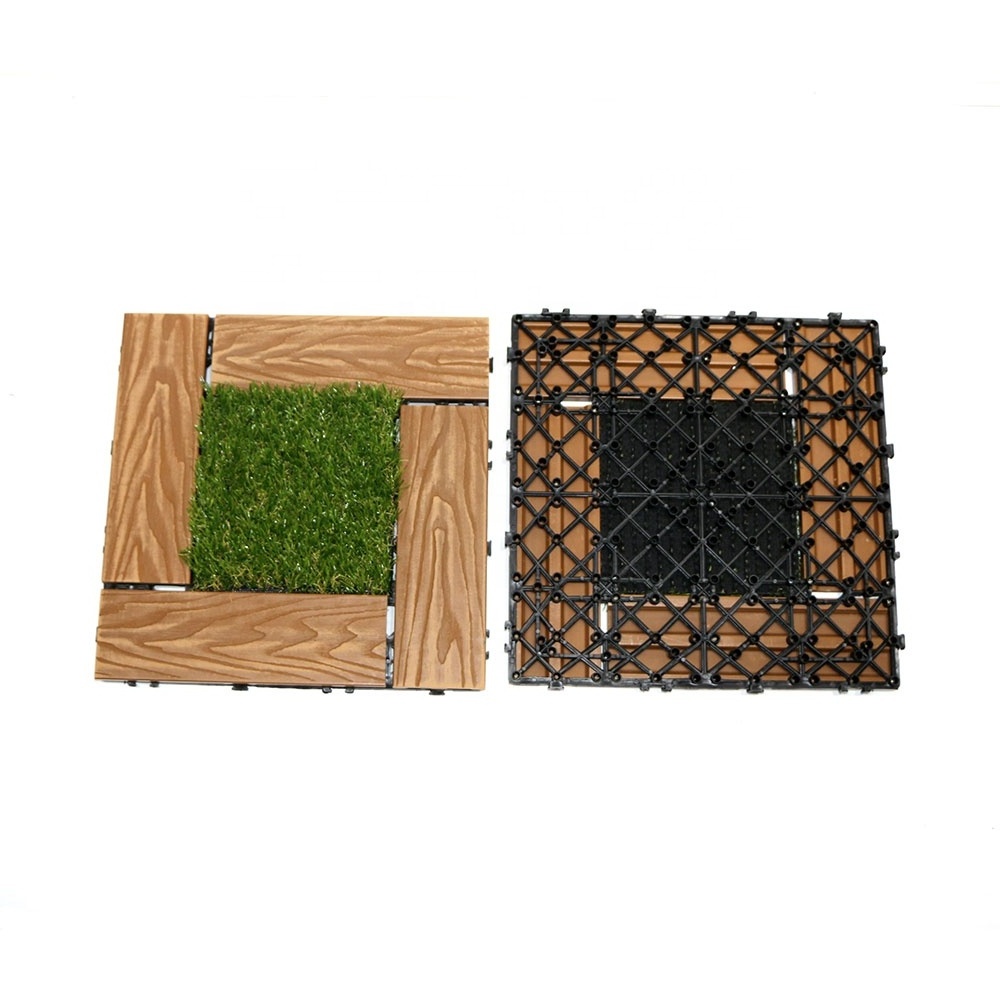

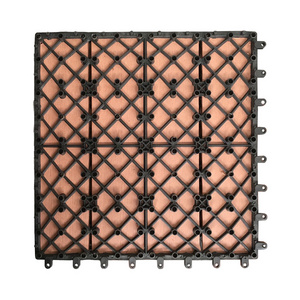

WPC, Wood + HDPE + Additives +Artificial Grass

-

Thickness:

-

22mm

-

Type:

-

WPC DIY decking with grass

-

Surface:

-

Wood grain and grass

-

Size:

-

300*300*22mm

-

Color:

-

Teak/Iron oxide red/Coffee/Brown reddish/Chocolate/Gray/Customized

-

Feature:

-

Anti-fading,crack resistant,kid friendly,heat resistance and so on

-

Certification:

-

Intertek , ISO9001, TUV and so on

-

Packing:

-

11 pcs per carton

Quick Details

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Outdoor

-

Design Style:

-

Modern

-

Warranty:

-

More than 5 years

-

Technics:

-

wood plastic composite

-

Place of Origin:

-

Zhejiang,China

-

Model Number:

-

BS-18

-

Brand Name:

-

KELAI DECKING

-

Material:

-

WPC, Wood + HDPE + Additives +Artificial Grass

-

Thickness:

-

22mm

-

Type:

-

WPC DIY decking with grass

-

Surface:

-

Wood grain and grass

-

Size:

-

300*300*22mm

-

Color:

-

Teak/Iron oxide red/Coffee/Brown reddish/Chocolate/Gray/Customized

-

Feature:

-

Anti-fading,crack resistant,kid friendly,heat resistance and so on

-

Certification:

-

Intertek , ISO9001, TUV and so on

-

Packing:

-

11 pcs per carton

Related Products

Product Description

Kelai DIY WPC decking is made of 60% wood fiber,30% HDPE and 10% Additives.

Surface: 3D Wood Grain and grass

These are all materials are very friendly.And it is anti-uv, crack-resistant, waterproof and anti-mite ect.However, the most important thing is that it doesn't need any maintenance.

Surface: 3D Wood Grain and grass

|

Product Features

|

|

|

|

*Brand

|

KELAI

|

|

|

*Type

|

WPC DIY decking with grass

|

|

|

*Model

|

BS-18

|

|

|

*Delivery Time

|

15-20 days after we recived the deposit

|

|

|

*Color

|

Teak/ red/Coffee/Brown Chocolate/Gray/Customized

|

|

|

3*Surface Treatment

|

3D wood grain

|

|

|

*Size

|

300*300*22mm

|

|

|

*Certification

|

Intertek , ISO9001, TUV ,FSC, CE

|

|

COLORS

APPLICATION

PACKING&SHIPPING

CETIFICATION

WORKSHOP

-

-

Raw Materials

-

Prilling

-

Extrusion

-

-

Embossing

-

Test

-

Packing

EXHIBITION

Company Introduction

Kelai was created to bring you the best wpc products from China.Our Team of professionals have many years of experience in the export and domestic market. Kelai is selling our

wpc products

to more than 30 countries around the world, like USA, Canada, Mexico, etc.

Our Services & Strength

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* Factory Visiting .

After-Sales Service

* installation instruction.

* testing reports offering.

* online information desk.

FAQ

Q:

What is the species of wood fiber you use?

A:

Eucalyptus, poplar and some mixed wood, which is color related.

Q:

What about your main market?

A:

The main market is always oversea. More than 90% of the products are for export, and main market is Greece, Czech Republic, Italy,Germany, Spain, Austria, Swiss, Estonia, Norway, UK, Korea, Thailand, Indonesia, Vietnam, USA, Canada, Argentina, Australia,etc.

Q:

Do your WPC products have color fading problem?

A:

To be honest, the products do have some color fading problem mostly during the first 6 months after installation, but not be obvious.

Q:

How many production lines you have? What about the production capacity per month?

A:

14 extrusions lines. 30-35 containers per month.

Q:

What properties will you test for your raw material and end products?

A:

Wood fiber: ash content, fiber size, water content.

HDPE: melting index, ash content, physical property test for finish product

End product: melting index, ash content, physical property test for finish product

End product: strength test, boiling test and expansion rate test, temperature cycle test, outdoor UV test

Q:

What about delivery time for one container?

A:

15-20 days upon deposit payment well received.

Q:

What about the temperature range of your WPC can be used?

A:

-40 to 60 degrees.

Q:

Have you ever received any complaints from your customers?

A:

Frankly speaking, yes. And it’s mainly about color difference, cause our raw material is recycled material, there is always

difference between different lots. Now mixing is done for our HDPE plastic and also after pelletizing to well control of this problem.

Hot Searches