- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongteng

-

Model Number:

-

K-1688

-

Focal Length:

-

Based on the model

-

Wavelength Range:

-

Based on the model

-

Product name:

-

handheld metal analyzer

-

Application:

-

Metal Elements Analysis

-

Certificate:

-

ISO 9001

-

Key words:

-

Spectrometer

-

Power Supply:

-

220V 50HZ

-

Wavelength accuracy:

-

0.1 Nm

-

Stability:

-

Stable

-

Sensitivity:

-

K:0.01ppm

-

Printer Type:

-

Wireless Bluetooth Printer

-

Advantage:

-

Long service time

Quick Details

-

Warranty:

-

1 years

-

Size:

-

Based on the model

-

Weight:

-

Based on the model

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongteng

-

Model Number:

-

K-1688

-

Focal Length:

-

Based on the model

-

Wavelength Range:

-

Based on the model

-

Product name:

-

handheld metal analyzer

-

Application:

-

Metal Elements Analysis

-

Certificate:

-

ISO 9001

-

Key words:

-

Spectrometer

-

Power Supply:

-

220V 50HZ

-

Wavelength accuracy:

-

0.1 Nm

-

Stability:

-

Stable

-

Sensitivity:

-

K:0.01ppm

-

Printer Type:

-

Wireless Bluetooth Printer

-

Advantage:

-

Long service time

PRODUCT SHOW

The K Series sets a new performance standard for handheld XRF. This instrument perfectly integrates the features of X series products such as small size, fast speed and high precision into one device. It is specially designed for NDT and PMI users to detect hard-to-reach test locations and welds. It has extraordinary analytical capabilities for low-content potassium and fennel.

K-1688 can analyze common alloys in 1 second or less. The system is built on the Microsoft WINCE platform, and the system has better compatibility with the computer platform to facilitate data communication. Users can use it easily as long as they know how to operate a computer.

Temporary files generated by the system operation will be automatically deleted after the instrument is restarted, and the machine can run as smoothly as new for 10 years. One-click system testing, from startup to testing in one step, testing has never been so convenient.

|

K Series Analysis Modes and Elements

|

|

|

|

Modle

|

Standard configuration mode analysis scope, if there are special elements additional elements can be added

|

|

|

K1688

|

Can analyze Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Se, Zr, Nb, Mo, Rh, Pd, Ag, Cd, Sn.Sb, Hf, Ta, W, Re, Pb, Bi, Au and other standard

elements

|

|

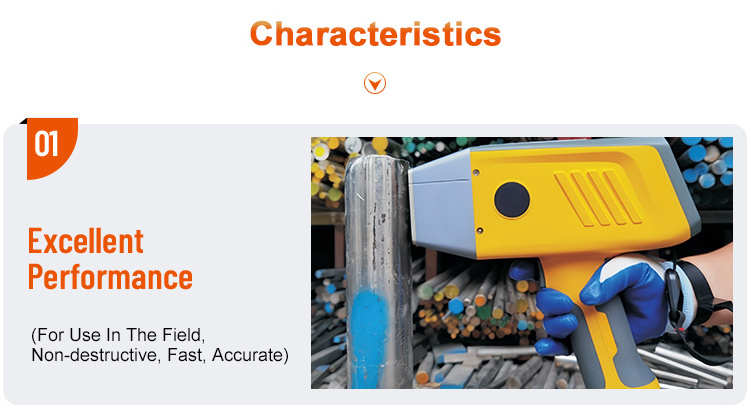

Application Fields and Characteristics

The element symbols are displayed in Chinese and English, with high precision and fast speed, close to laboratory-level analysis level.

It can visually display the alloy grade and element percentage content (elements can reach three decimal places) and ppm content. The entire analysis process only takes a few seconds to complete, and alloy grade identification only takes 1 to 2 minutes. It is a one-click operation that even non-technical personnel can easily master.

Non-destructive testing (NDT) It does not damage or affect the performance of the tested object, does not harm the internal tissue of the tested object, and there is no damage during the entire testing process.

K-max analysis software Professional management and analysis software allows you to easily set a secure user password, customize and personalize analysis reports with company logo, and easily realize remote control of the instrument; users can edit the alloy grade library, Add alloy grades and enterprise-defined grades; automatically calibrate and diagnose instrument faults; software upgrades can be achieved through the Internet.

Waste recycling and sorting Recycling and reuse of scrap metal, conducting on-site analysis, testing and sorting of complex and diverse alloy types and materials. It enables buyers and sellers to make quick and reliable judgments during transactions. Quantitative analysis of metal components such as ferroalloys (stainless steel, etc.), copper alloys, aluminum alloys, copper-iron alloys, lead-tin alloys, mixed alloys, and rapid on-site material identification and sorting.

PACKING & DELIVERY

Recommend Products

ABOUT US

Hongteng is a High-tech enterprise and a municipal Research & Development center. We have more than

10 technicians

with over

5 years of industry experience

. Company owned more than

20 kinds

of spot products, we accept

OEM and ODM

We have

CE and ISO9001 certification

, guaranteed product quality Hongteng products exported to more than

35 countries.

Hot Searches