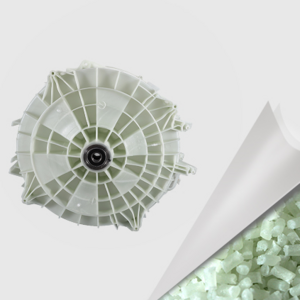

PP can adapt to a wider range of application requirements through modifying, copolymerization, grafting,blending, reinforced

filling, transparency, filling, weather resistance.

2

.It is a colorless translucent thermoplastic lightweight general purpose plastic with chemical resistance, heat resistance,

electrical insulation, high strength mechanical properties and good high wear-resisting machining properties [1]. It is widely

used in the production of clothing, blankets and other fiber products, medical instruments, automobiles, bicycles, spare parts,

transportation pipes, chemical containers, and also used in food and medicine packaging.

electrical insulation, high strength mechanical properties and good high wear-resisting machining properties [1]. It is widely

used in the production of clothing, blankets and other fiber products, medical instruments, automobiles, bicycles, spare parts,

transportation pipes, chemical containers, and also used in food and medicine packaging.