- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SAIWEI

-

Year:

-

2022

-

Power (kW):

-

5.5

-

Weight (KG):

-

500

Quick Details

-

Max. Bending Angle (Deg):

-

360

-

Bending Precision (Deg):

-

Contact Us

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SAIWEI

-

Year:

-

2022

-

Power (kW):

-

5.5

-

Weight (KG):

-

500

Products Description

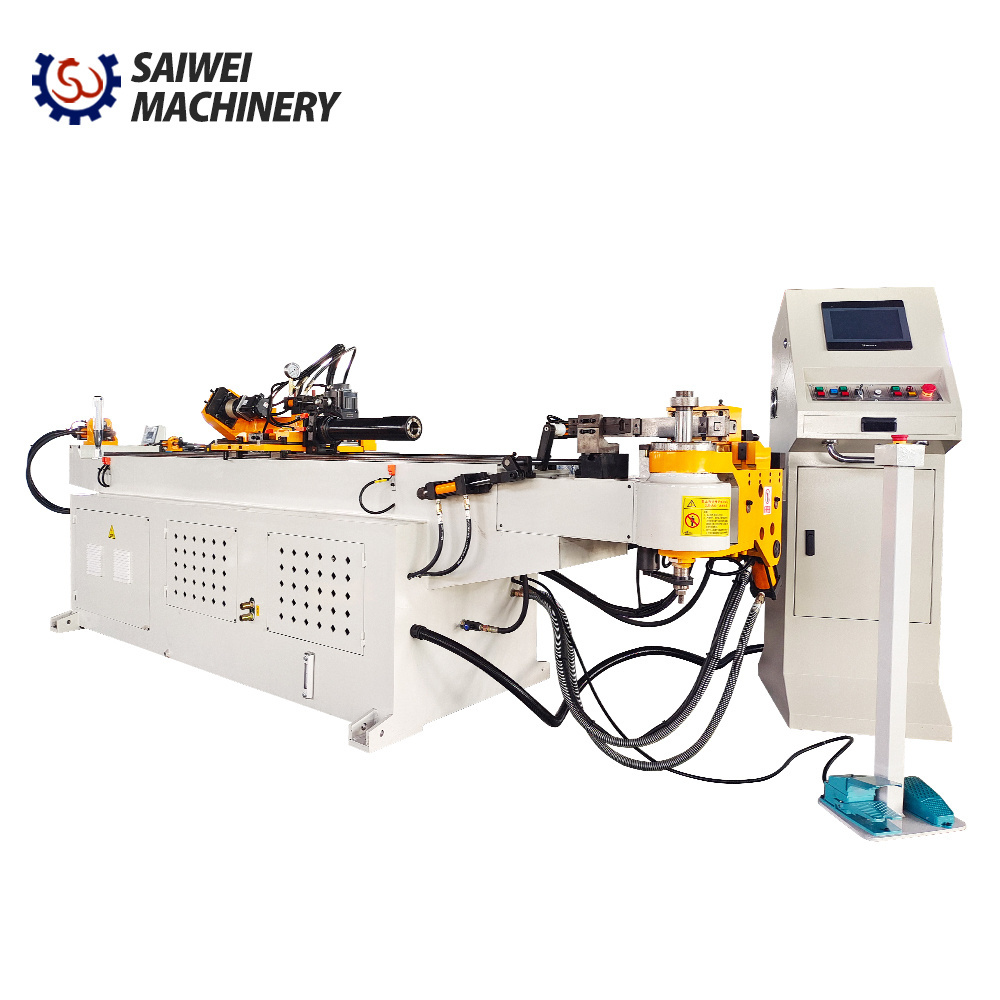

Introduction to CNC controlled hydraulic pipe bending machine

The bending pipe is driven by servo, which is strong and powerful.

The corner and feeding are driven by servo motors, which are fast and accurate.

Simultaneously storing multiple sets of processing programs and being able to switch flexibly facilitates the processing of a wide variety of products, greatly improving production efficiency.

It has the function of automatically detecting errors and faults. When there is any abnormal action or any danger, the machine will immediately stop and issue an abnormal alarm to help the operator troubleshoot,

Especially suitable for processing pipe fittings with multiple spatial angles and high precision requirements. For example, the production and production of car oil pipes, air conditioning pipes, motorcycle and bicycle frames

Equipped with automatic error detection and fault detection function, and displayed on the screen, making it easy for operators to eliminate obstacles. All processing data is input by the touch screen, and after input, the shape can be displayed on the industrial computer panel for bending feasibility simulation to detect possible interference steps and points during the bending process. Each bend pipe can have compensation values, speeds, and demolding clearances set according to different material changes.

Each bend of the same pipe can be individually programmed with 5 action sequences and 10 speeds, allowing operators to use them in combination to improve work efficiency and reduce pipe interference points.

The touch screen can switch between Chinese and English. Display other languages and order according to demand. Optional manual/automatic, half cycle/full cycle, no core/with core threading, no auxiliary push/with auxiliary push, auxiliary push single action/auxiliary push linkage

The feeding method can be selected as direct or clamp feeding according to different needs

Input method is YBC

After the data is edited, it is protected by a key to prevent arbitrary modification of the data

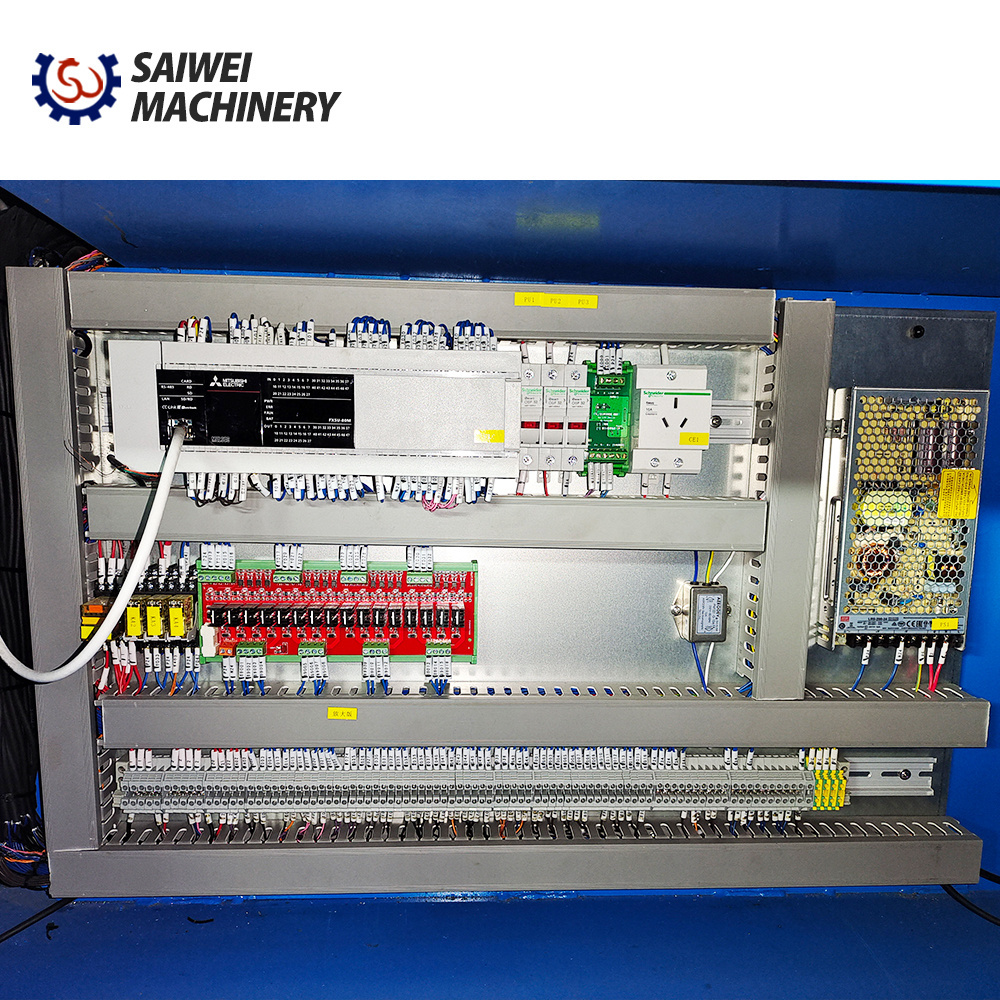

The electronic control system is equipped with a heat exchanger for automatic heat dissipation. If necessary, CNC air conditioners can be purchased to ensure the lifespan of the electronic control system.

The installation of an automatic oil filling system on the machine can reduce the friction of the bent pipe, improve the service life of the core rod, and ensure the quality of the bent pipe.

Can be connected to a printer to print out the information displayed on the screen

The machine can be equipped with a communication interface and a data machine. Remote control, troubleshooting, etc

The feeding position, safety position, mold interference position, and guide mold interference position of the feeding cart can be manually adjusted and automatically memorized to eliminate human measurement errors and machine collision losses.

The feeding shaft will automatically detect before operation to avoid collision with the machine

During actual bending, the disassembly action can be selected to observe the interference point, modify the action, and improve efficiency. The mobile foot switch combines two functions: start and emergency stop

The machine is equipped with an automatic lubrication system to protect the transmission components of the machine and improve its service life. Additional standalone control software can be purchased, which can be used to monitor device usage in the office

|

Model

|

DW-38CNC

|

DW-50CNC

|

DW-63CNC

|

DW-75CNC

|

|||

|

Maximum bending diaeter and wall thickness

|

Φ38x2mm

|

Φ50x3mm

|

Φ63x4mm

|

Φ75x4mm

|

|||

|

Maximum bending radius

|

R180mm

|

R250mm

|

R250mm

|

R300mm

|

|||

|

Maxcimum bending angle

|

190°

|

190°

|

190°

|

190°

|

|||

|

Maxdmum feed length

|

2200mm

|

2500mm

|

3000mm

|

3000mm

|

|||

|

Feeding mode

|

Direct or pinch delivery

|

Direct or pinch delivery

|

Direct or pinch delivery

|

Direct or pinch delivery

|

|||

|

Elbow speed

|

Max 150°s

|

Max 85°s

|

Max 85°s

|

Max 40°s

|

|||

|

Transfer rate

|

Max 200°/s

|

Max 200°/s

|

Max 200°/s

|

Max 160°/s

|

|||

|

Feeding speed

|

Max 1000mm/s

|

Max 1000mm/s

|

Max 1000mm/s

|

Max 800mm/s

|

|||

|

Ebow precision

|

±0.1°

|

±0.1°

|

±0.1°

|

±0.1°

|

|||

|

Transfer accuracy

|

±0.1°

|

±0.1°

|

±0.1°

|

±0.1°

|

|||

|

Feeding accuracy

|

±0.1mm

|

±0.1mm

|

±0.1mm

|

±0.1mm

|

|||

|

Data entry mode

|

1、Coordinate (X.Y.Z) 2、working value (Y.B.C)

|

|

|

|

|||

|

Bending mode

|

1、Servo bending pipe: 5kw (more than three axes) 2、Hydraulic bending pipe

|

|

|

|

|||

|

Rotary pipe servo motor power

|

750w

|

750w

|

750w

|

1kw

|

|||

|

Feeding servo motor power

|

1kw

|

1.5kw

|

1.5kw

|

1.5kw

|

|||

|

Elbow number

|

1、16 pieces (PLC type) 2、33 pieces (industrial computer type)

|

|

|

|

|||

|

Can store part number

|

1、1000 sets (PLC type) 2、Two million sets (industrial computer type) 5.5kw

|

|

|

|

|||

|

Hydraulic motor power

|

4kw

|

5.5kw

|

5.5kw

|

7.5kw

|

|||

|

Maximum syster pressure (adjustable)

|

12Mpa

|

12Mpa

|

12Mpa

|

12Mpa

|

|||

|

Machine weight

|

1500kg

|

2500kg

|

3000kg

|

4500kg

|

|||

|

Model

|

DW-89CNC

|

DW-114CNC

|

DW-130CNC

|

DW-168CNC

|

|||

|

Maximum bending diaeter and wall thickness

|

Φ89x6mm

|

Φ114x8mm

|

Φ130x8mm

|

Φ168x14mm

|

|||

|

Maximum bending radius

|

R300mm

|

R450mm

|

R450mm

|

R600mm

|

|||

|

Maxcimum bending angle

|

190°

|

190°

|

190°

|

190°

|

|||

|

Maxdmum feed length

|

3000mm

|

3000mm

|

3000mm

|

3500mm

|

|||

|

Feeding mode

|

Direct or pinch delivery

|

Direct or pinch delivery

|

Direct or pinch delivery

|

Direct or pinch delivery

|

|||

|

Elbow speed

|

Max 30°s

|

Max 30°s

|

Max 30°s

|

Max 30°s

|

|||

|

Transfer rate

|

Max 160°/s

|

Max 160°/s

|

Max 160°/s

|

Max 160°/s

|

|||

|

Feeding speed

|

Max 800mm/s

|

Max 800mm/s

|

Max 800mm/s

|

Max 800mm/s

|

|||

|

Ebow precision

|

±0.1°

|

±0.1°

|

±0.1°

|

±0.1°

|

|||

|

Transfer accuracy

|

±0.1°

|

±0.1°

|

±0.1°

|

±0.1°

|

|||

|

Feeding accuracy

|

±0.1mm

|

±0.1mm

|

±0.1mm

|

±0.1mm

|

|||

|

Data entry mode

|

1、Coordinate (X.Y.Z) 2、working value (Y.B.C)

|

|

|

|

|||

|

Bending mode

|

1、Servo bending pipe: 5kw (more than three axes) 2、Hydraulic bending pipe

|

|

|

|

|||

|

Rotary pipe servo motor power

|

1.5kw

|

2kw

|

2kw

|

3kw

|

|||

|

Feeding servo motor power

|

2kw

|

3kw

|

3kw

|

4kw

|

|||

|

Elbow number

|

1、16 pieces (PLC type) 2、33 pieces (industrial computer type)

|

|

|

|

|||

|

Can store part number

|

1、1000 sets (PLC type) 2、Two million sets (industrial computer type) 5.5kw

|

|

|

|

|||

|

Hydraulic motor power

|

11kw

|

22kw

|

22kw

|

30kw

|

|||

|

Maximum syster pressure (adjustable)

|

14Mpa

|

14Mpa

|

14Mpa

|

14Mpa

|

|||

|

Machine weight

|

5500kg

|

6800kg

|

7800kg

|

1200kg

|

|||

|

Application industry

|

|

|

|

|||

|

Furniture

|

Boiler

|

Exhaust

|

Shipyard /oil rig

|

|||

|

Head rest

|

Heavy vehicle cabin

|

Green house

|

Health care

|

|||

|

Aerospace/aviation

|

Serpentine bending

|

Fitness

|

Brake line

|

|||

Sample Display

Application Scenarios

Hot Searches