- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

20

-

Application:

-

panel stick the decorative film

-

Keywords:

-

lamianting

-

working width:

-

1300 1650 1900

-

press:

-

roller press

-

glue coater:

-

silicon rubber roller with size190mm

-

glue scraping roller:

-

steel roller with size 160mm

-

conveying roller:

-

rubber roller wiht size 190mm

-

hot pressing roller:

-

steel roller with 1.5kw heating lamps

-

cold pressing roller:

-

rubber roller with diameter 190mm

-

Capacity:

-

4 baord per min

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZHC

-

Weight (KG):

-

2000 KG

-

Power (kW):

-

20

-

Application:

-

panel stick the decorative film

-

Keywords:

-

lamianting

-

working width:

-

1300 1650 1900

-

press:

-

roller press

-

glue coater:

-

silicon rubber roller with size190mm

-

glue scraping roller:

-

steel roller with size 160mm

-

conveying roller:

-

rubber roller wiht size 190mm

-

hot pressing roller:

-

steel roller with 1.5kw heating lamps

-

cold pressing roller:

-

rubber roller with diameter 190mm

-

Capacity:

-

4 baord per min

Product Description

Paper and PVC film lamianting machine

roller press mdf panel laminating machinery

white glue panel laminating machine

paper sticking machine

furniture board laminating line

hot and cold glue machine for paper

sheet by sheet glue pasting sticking machine

This type machine is the best choice for laminate decorative material (PVC,PE, wood grain paper etc.)on the surface of the flat board(MDF board,density board, particle board, aluminum panel,steel panel,PVC panel etc.It equipped with dust-cleaning part, glue coating machine,glue heating part, cold and hot pressure part,can finish dust-cleaning, glue coating, hot & cold pressure, material sticking.The final product has a flat surface without wrinkles

the application

The glue : the white glue, water based or oil based PU glue and other glue can coat and stick in the common temperature.

The panel :MDF/HDF, Particleboard, MGO board,WPC board,PVC board,plywood board, gypsum board, foamed board, etc. All the board surface must be flat and mo more than 0.2mm.

The decorative material: HPL/CPL, the PVC film, PU paper, Kraft paper, paint paper, cloth, leather, wooden veneer.the material must be roller.

the reference machinery picture

Technical parameters

Paper and PVC film lamianting machine

| Item | 1350TZ-D |

| Pressing roller control |

air cylinder(when change thickness of the panel, need to adjust the air cylinder one by one) |

| Main body of the machine | Made by 14mm steel plate |

| Voltage | 380V/50HZ |

| Rated power | 18KW |

| Glue coating roller | φ190x1350mm( silicone ) |

| Heating steel Pressing roller | φ190x1350mmx2PCS |

| Rubber pressing roller | φ190x1350mmx2PCS |

| Max processing thickness | 50mm |

| Max.work width | 1350mm |

| working speed | 1-15m/min |

| Overall dimensions | 9600*2300*1600mm |

| Machine weight | 2000kgs |

| Delivery time | Within 15 working days |

| Terms of payment | 30%deposit, paid off the balance before delivery. |

Detail information with pictures for

Paper and pvc film laminating machine

1st the strong and stabilization machine body.

Paper and PVC film lamianting machine

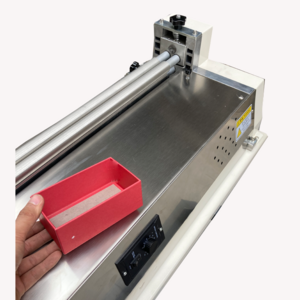

The glue coating part

1:Steel roller together with rubber roller makes the glue coating more uniform.

2:The machine adopt big glue box, adding glue will be more convenient and quick.

3:Main body made by 16mm thickness steel panel,make sure the service life of the machine longer

The pressing part

Paper and PVC film lamianting machine

1:Two sets of hot steel pressing roller together with two sets of cold rubber pressing roller.

2:The steel rollers continuous heating in a constant temperature to make sure the surface much more flat.

3:Main body made by 16mm thickness steel panel,make sure the service life of the machine longer

the samples showing

Paper and PVC film lamianting machine

This photo shows laminate pvc film on Particle board,the surface is flat and strong.