- Product Details

- {{item.text}}

Quick Details

-

Heating Power (kW):

-

140 kW

-

Production Speed(times/h):

-

1080

-

Power Supply:

-

380V/50HZ

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FS

-

Voltage:

-

AC 380/220V

-

Dimension(L*W*H):

-

12000x2000x26000mm

-

Weight (T):

-

28 T

-

After-sales Service Provided:

-

Video technical support, Online support

-

Material:

-

PS

-

Products:

-

Lunch box,plate,tray,bowl and so on

-

Max forming area:

-

1100mmx1400mm

-

Forming pressure:

-

20t (adjustable)

-

Forming mold:

-

Vacuum forming, press forming, mould forming, comprehensive forming

-

Production efficiency:

-

3-5 seconds/mould

-

Delivery time:

-

60 working days

-

Power:

-

140Kw

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Max.Forming Height(mm):

-

50 mm

-

Forming Width (mm):

-

1100 mm

-

Forming Length (mm):

-

1400 mm

-

Heating Power (kW):

-

140 kW

-

Production Speed(times/h):

-

1080

-

Power Supply:

-

380V/50HZ

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FS

-

Voltage:

-

AC 380/220V

-

Dimension(L*W*H):

-

12000x2000x26000mm

-

Weight (T):

-

28 T

-

After-sales Service Provided:

-

Video technical support, Online support

-

Material:

-

PS

-

Products:

-

Lunch box,plate,tray,bowl and so on

-

Max forming area:

-

1100mmx1400mm

-

Forming pressure:

-

20t (adjustable)

-

Forming mold:

-

Vacuum forming, press forming, mould forming, comprehensive forming

-

Production efficiency:

-

3-5 seconds/mould

-

Delivery time:

-

60 working days

-

Power:

-

140Kw

-

Marketing Type:

-

Hot Product 2022

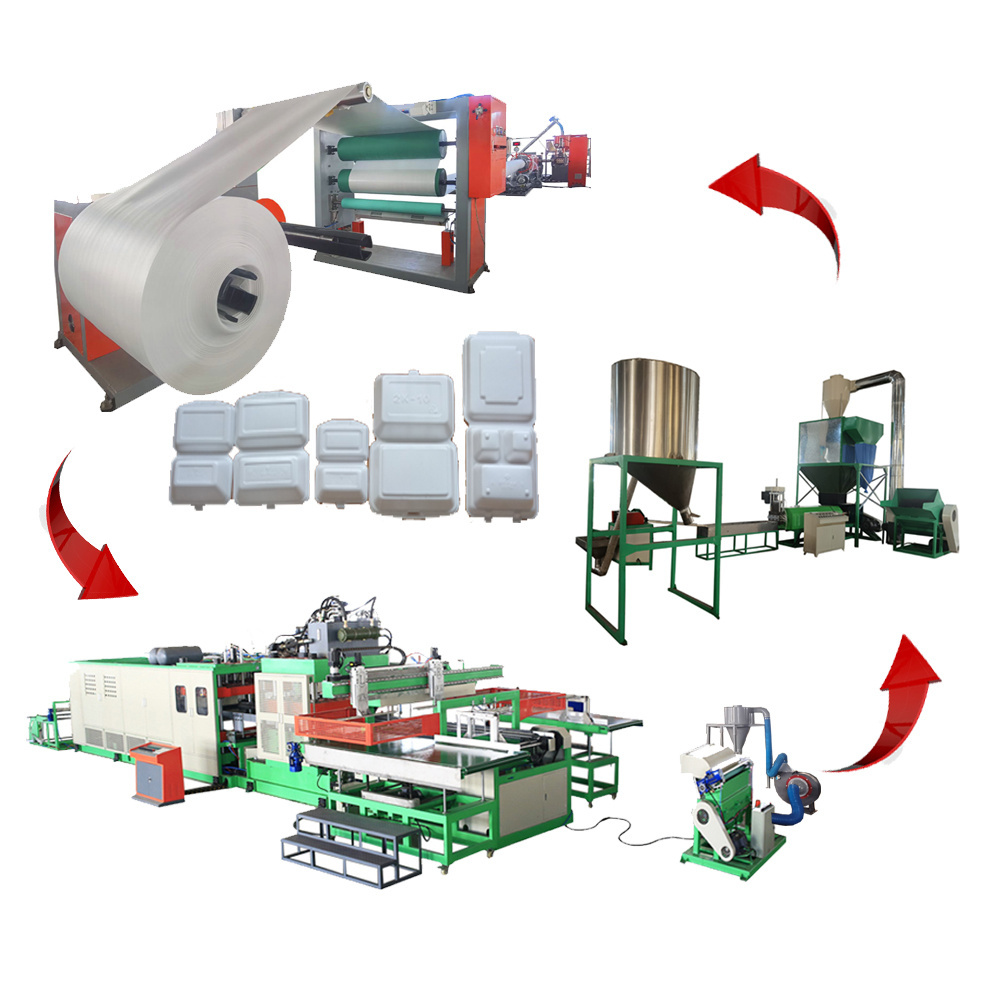

Product Application

PS disposable foam food container vacuum forming cutting & stacking machine

with robot hands makes different kinds type of fast food box, foam tray, foam plate, foam container and so on. If so, you need many moulds.

This type of developed by combining the domestic equipment and advantages, is a set of hydraulic pneumatic servo drive for an automatic forming cutting seek. Mainly by electrical components, Japan and Germany pump, ensure the reliability of the equipment operation, and can be used for hot forming process many kinds of plastic material, it can produce PS packaging products, materials used in food, medical supplies, electrical components, tourism products, toys, textile, etc.

Advantage:

1. Suck and pull the food containers up. Even the containers don't be sucked out successfully, this won't affect next move

2. There are one conveyor belt on each side, both can achieve automatically stacking, reduce labor intensity

3. Heater box separate into three parts, hydraulic cutting speed is faster, and use mechanical arms to suck products, all above methods reduce the whole working time

4. Extend mold length, making the forming mold area larger and improving the production efficiency

5. Stacking system installed two sets of static eliminator to eliminate static electricity generated in the production process to avoid fires

Unwinding portion

1. Unwinding length: Photoelectric switch control

2. Unwinding mode:0.75kw turbine decelerating motors

3. Feeding method: Pneumatic feeding

4. Double feeding shaft alternately

Heating portion

1. Heating area:1200×4400(mm)

2. Heating mode: Ceramic tile radiation

3. Heating power:160kw

4.Heating box can be moved back and forth, left and right.

5. Heating box full use of heat insulation material, to prevent the heat loss and save energy.

6. Temperature control: intelligent temperature controller and temperature control module, to control temperature and adjust the both sides voltage of heater, keeping heater constant temperature heating status.

Vacuum Forming portion

1. Max forming area: 1100×1400(mm)

2. Forming model: Vacuum forming, press forming, mold forming and comprehensive forming

3. Forming depth: Max 80mm

4. Forming pressure: Max 35t,adjustable

5. Machine control method: Hydraulic control of the upper and lower mold alone

6. The production efficiency: 3-4 seconds/mold

7. Working table stroke: Photoelectric switch automatic control

Cutting portion

1. Punching pressure: Max 120T

2. Punching mode: Hydraulic automatic control

3. Working table stroke: Photoelectric switch automatic control

4. Punching plate: High quality stainless steel

5. Punching area: 1100×1400(mm)

6. Cutting area can move: Driven by the motor, it is beneficial for changing the moulds and can save the time of changing moulds.

7. Electrostatic eliminators are set on cutting and stacking area, it can eliminate the static produced during the forming process. Make sure the production safety.

Stacking collection system

1. Control method: Controlled by PLC

2. Stacking method: The servo motor control the mechanical arms reciprocating motion, the mechanical arms catch the plate by vacuum sucker, it uses conveyor belt to collect the plate from both sides, and can stack 25pcs plates for single row, it is convenient to put in the carton box or bag.

3.

Transmission mode :Double conveyor belt transmission

4. Control mode:The servo motor control

Waste broken collection

1. Traction transmission: motor power 0.75kw

2. Crusher: motor power:7.5kw

3. Suction fan power:3kw

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Leading Time

Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

PS Foam Food Container Production Line

97.8% Response Rate

EPE Foam Sheet Extrusion Line

86.8% Response Rate

PS Foam Sheet Extrusion Line

96.8% Response Rate

Q1: Why I choose your company?

A:1) We are one of the leading manufacturers of packing materials and related machinery .

2) Our company has made foam machine about 20 years with strong experience and advanced techniqu

3) Best Quality & Best Service with Competitive price. 1 year guarantee and lifetime maintenance

4) We have CE certificate and ISO 9001

5) We have Professional technical team, and will supply 24 hours service

Q2: What should we prepare for PS disposable foam food container making machine

A:You should prepare raw material(GPPS), workshop, water line, electric line, gas, compress air(if you need I can help you buy air compressor). We would supply workshop layout drawing for you.

Q3: Where is your factory located? How can I visit there?

A: Our factory is located in Longkou city, Shandong province, you can fly to Yantai Penglai International Airport.When you confirm the flight No. and time, please tell me then we will pick you up at Airport.