- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4150*850*1500mm

-

Power (kW):

-

11.6 KW

-

Weight (KG):

-

1200 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Product name:

-

Automatic Mdf Edge Banding Machine

-

Panel width(min):

-

50mm

-

Feeding speed:

-

16 M/'min

-

Work piece thickness:

-

10-60mm

-

Band width:

-

12-65mm

-

Band thickness:

-

0.4-3mm

-

Pneumatic pressure:

-

0.6Mpa

-

Machine weight:

-

1200 KG

-

Touch Screen:

-

DELTA

-

PLC:

-

DELTA

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HaiXun

-

Voltage:

-

220v/380v/440v

-

Dimension(L*W*H):

-

4150*850*1500mm

-

Power (kW):

-

11.6 KW

-

Weight (KG):

-

1200 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Product name:

-

Automatic Mdf Edge Banding Machine

-

Panel width(min):

-

50mm

-

Feeding speed:

-

16 M/'min

-

Work piece thickness:

-

10-60mm

-

Band width:

-

12-65mm

-

Band thickness:

-

0.4-3mm

-

Pneumatic pressure:

-

0.6Mpa

-

Machine weight:

-

1200 KG

-

Touch Screen:

-

DELTA

-

PLC:

-

DELTA

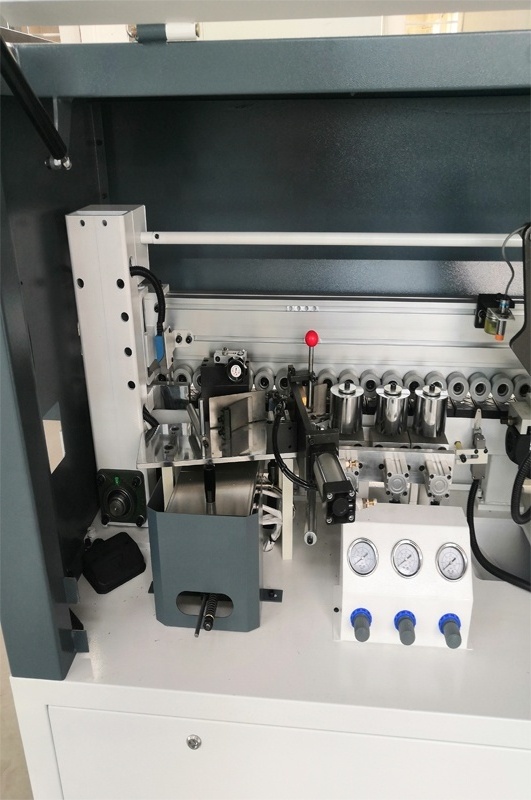

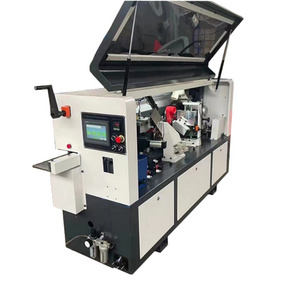

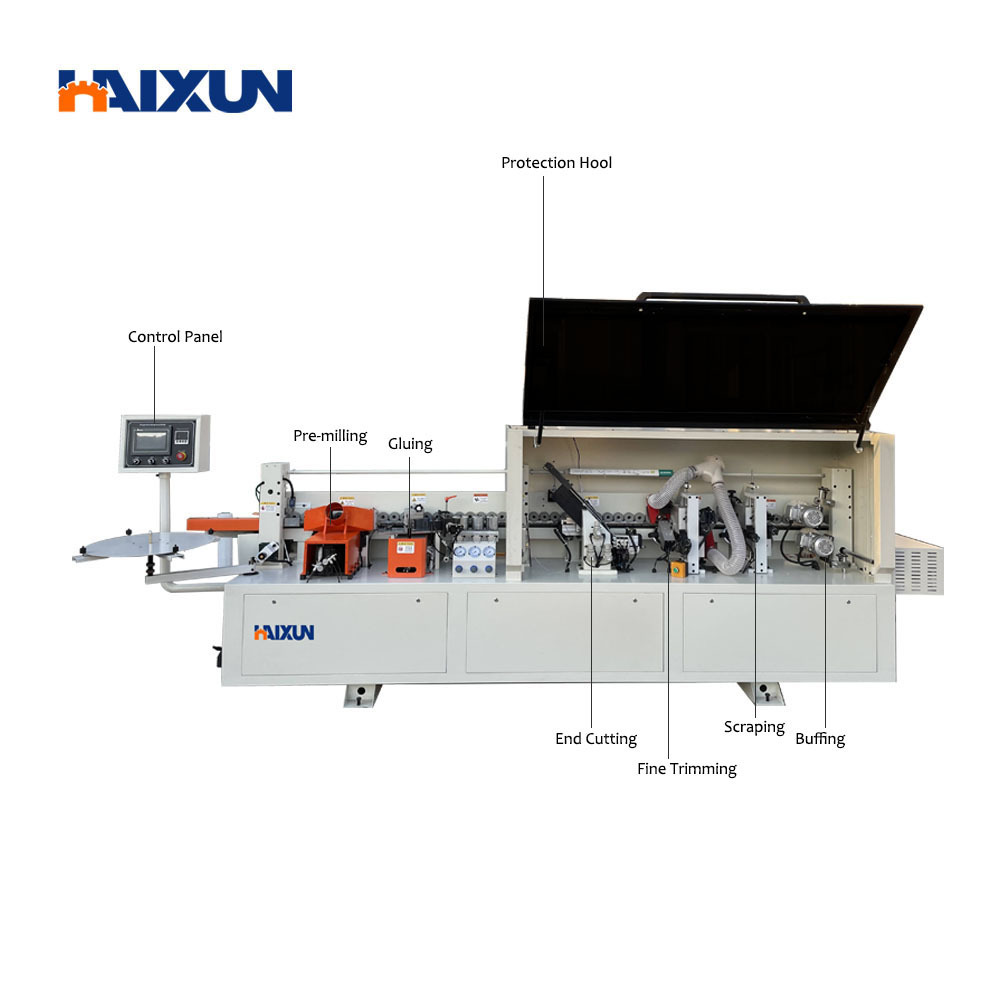

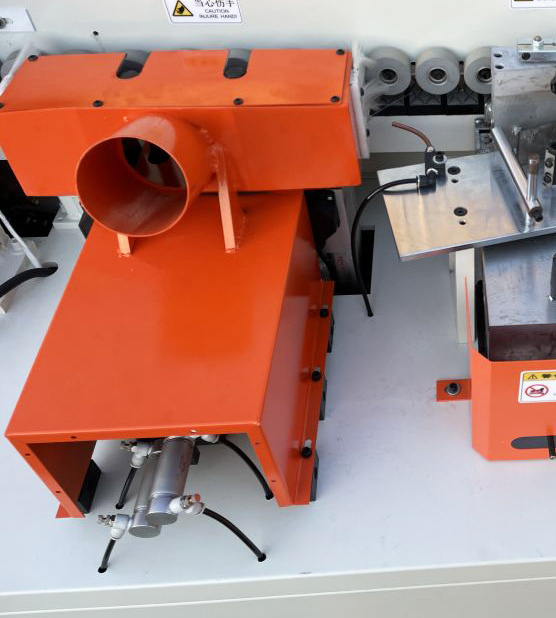

Step 1: Pre-milling

pre-milling equipment with double trimming blades works on the waves effect that is caused by precise sliding table saw.

Step 2:Glue and Pressing

The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination

Step3:End Cutting

The end trimming mechanism through a high precision linear guide rail, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly

Step4:Fine trimming

Used for cutting the excess edge materials,adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly

Step5:Scraping

For a perfect finishing of the applied edge

Step6:Buffing

Adopt the board processed by two cotton polishing wheel, by end-polishing to make the edge side even more smoother surface

|

Edge Banding Machine

|

HX-505JS

|

|

|

|

|||

|

Key Word

|

Edge banding machine

|

|

|

|

|||

|

Motor Power

|

11.6 KW

|

|

|

|

|||

|

Overall size

|

4150*850*1500mm

|

|

|

|

|||

|

Feed speed

|

12-20m/min

|

|

|

|

|||

|

Panel thickness

|

10-60mm

|

|

|

|

|||

|

Belt thickness

|

0.4-3mm

|

|

|

|

|||

|

Min. width of panel

|

≥80mm

|

|

|

|

|||

|

Working air pressure

|

0.6-0.8 Mpa

|

|

|

|

|||

|

Weight

|

1200KG

|

|

|

|

|||

Features

1,It suits for PVC, Melamine and thin batten etc, edge banding material.

1,It suits for PVC, Melamine and thin batten etc, edge banding material.

2,Using high-speed “CNC” control system, tail the processand protect machine from malfunction automatically.

3,Smart frame designing, high precise processing, make a good-looking and

smooth effect for trimming.

4,Using frequency-conversion feeding, crossbeam up-and-down by electromotion, full-close safety shield, more human operation.

5,High quality electric components and transmitting components make machine’s functions more steady

.

1.QINGDAO HAIXUN

have been committed to the research and manufacture of edge banding machines. A technology-knowledge-intensive enterprise specializing in the manufacture of woodworking machinery and equipment integrating development, manufacturing, sales and service.

2.The main products include: semi-automatic edge banding machines, automatic edge banding machines, manual edge banding machines, panel saws, CNC machining centers, woodworking drills, mechanical accessories, etc. Our products are widely used in custom furniture, solid wood furniture, solid wood carving, etc. We can provide you with high-quality products at competitive prices.

3.Our products have obtained CE certificates. Our main products are as follows: semi-automatic edge banding machine, automatic edge banding machine, manual edge banding machine, panel saw, CNC machining center, woodworking drill row, mechanical accessories, etc.

1. who are we?

We are based in Shangdong, China, start from 2019, Major market : Southeast Asia(20.00%),Africa(20.00%). There are total about

11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Woodworking machinery,Automatic edge banding machine,Engraving machine,Panel saw,CNC machining center

4. why should you buy from us not from other suppliers?

We have been committed to the research and manufacture of edge banding machines. A technology-knowledge-intensive enterprise

specializing in the manufacture of woodworking machinery and equipment integrating development, manufacturing, sales and service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;Accepted Payment

Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

We are based in Shangdong, China, start from 2019, Major market : Southeast Asia(20.00%),Africa(20.00%). There are total about

11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Woodworking machinery,Automatic edge banding machine,Engraving machine,Panel saw,CNC machining center

4. why should you buy from us not from other suppliers?

We have been committed to the research and manufacture of edge banding machines. A technology-knowledge-intensive enterprise

specializing in the manufacture of woodworking machinery and equipment integrating development, manufacturing, sales and service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;Accepted Payment

Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Hot Searches