- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V,60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Landpack

-

Dimension(L*W*H):

-

(L)1600*(H)1300*(W)1600mm

-

Weight:

-

400 KG

-

Product name:

-

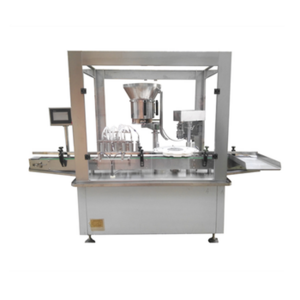

Full Automatic Liquid Filling Machine

-

Filling speed:

-

20-35 Bottles/min

-

Filling range:

-

50-1000 ml range

-

Suitable for:

-

Liquids

-

Model:

-

LFYT-00

-

Advantage:

-

15 Years Experiences

-

Filling head:

-

2 Heads

-

Airconsumption:

-

0.8-1.2m³/min

-

Equipment material:

-

304

-

After Sales Service:

-

Online Support, instruction books, site support

Quick Details

-

Machinery Capacity:

-

Other, 400BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH, 20-35 PCS/min

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, hand soap, Honey, Detergent Liquid, Liquid

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V,60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Landpack

-

Dimension(L*W*H):

-

(L)1600*(H)1300*(W)1600mm

-

Weight:

-

400 KG

-

Product name:

-

Full Automatic Liquid Filling Machine

-

Filling speed:

-

20-35 Bottles/min

-

Filling range:

-

50-1000 ml range

-

Suitable for:

-

Liquids

-

Model:

-

LFYT-00

-

Advantage:

-

15 Years Experiences

-

Filling head:

-

2 Heads

-

Airconsumption:

-

0.8-1.2m³/min

-

Equipment material:

-

304

-

After Sales Service:

-

Online Support, instruction books, site support

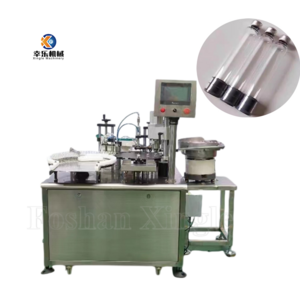

Industrial Automatic 3ml 50ml Perfume Liquid Vial Filling Stoppering Capping Machine

Recommend Products

Contact us

Feature

1. The

ceramic pump filling machine

is a

high-accuracy

filling machine. Widely used in advanced cosmetics, skin care products. High installation accuracy, convenient and flexible use.

3. Program control adopts PLC + touch screen manual operation interface to realize intelligent control.

4. The filling nozzle is made of stainless steel 304 , which is corrosion-resistant and meets GMP production requirements.

5. The material of the feeding hose is PVC , the temperature range: -10 ℃ ~ + 90 ℃.

6. A total of 5 servo controls , two control ceramic pump, two control screw cap, one control turntable.

7. Double vibrating plate , realize automatic tube loading and capping, two filling heads, two capping screw, speed up to 20-40 PCS/min ;

8. Because the bottle can not stand, use the horizontal roll labeling machine.

Control

PLC touch screen control panel, visualization of working parameters, simple operation interface, and the fastest basis for machine conditions. 15 different national operating languages for wider applicability.

Ceramic Plunger Pump

Using a ceramic column pump with higher metering accuracy can ensure that the filling error is below 0.25%

Filling

The size of the tray and the number of filling heads can be customized according to the needs of filling

Circuit layout

The drawer type design makes the circuit layout of the machine clearer and easier to maintain. Reasonable circuit distribution greatly improves the stability of the machine

2.

Equipped with no bottle and no filling function

, the liquid level automatically controls feeding, effectively reducing equipment failure.

3. Program control adopts PLC + touch screen manual operation interface to realize intelligent control.

4. The filling nozzle is made of stainless steel 304 , which is corrosion-resistant and meets GMP production requirements.

5. The material of the feeding hose is PVC , the temperature range: -10 ℃ ~ + 90 ℃.

6. A total of 5 servo controls , two control ceramic pump, two control screw cap, one control turntable.

7. Double vibrating plate , realize automatic tube loading and capping, two filling heads, two capping screw, speed up to 20-40 PCS/min ;

8. Because the bottle can not stand, use the horizontal roll labeling machine.

Control

PLC touch screen control panel, visualization of working parameters, simple operation interface, and the fastest basis for machine conditions. 15 different national operating languages for wider applicability.

Ceramic Plunger Pump

Using a ceramic column pump with higher metering accuracy can ensure that the filling error is below 0.25%

Filling

The size of the tray and the number of filling heads can be customized according to the needs of filling

Circuit layout

The drawer type design makes the circuit layout of the machine clearer and easier to maintain. Reasonable circuit distribution greatly improves the stability of the machine

Product Paramenters

|

Model

|

LFYT-00

|

|

Filling Range

|

50-1000ml(customizable)

|

|

Filling Speed

|

20-40 Bottles/min (100-500ml range)

|

|

Measurement Accuracy

|

±1%

|

|

Bottle Diameter

|

Φ10mm-Φ25mm(customizable)

|

|

Bottle Height

|

30mm-150mm(customizable)

|

|

Control system

|

PLC

|

|

Total production line power

|

1.2 KW

|

|

Power supply

|

220V、50Hz

|

|

Airconsumption

|

0.8-1.2m³/min

|

|

Equipment material

|

304

|

Application

All kinds of test tubes,

perfume,

laboratory liquid,

sanitizer,

reagent,

oil,

cell testing fluids, nucleic acid testing fluids and other liquids;

Filling container:

test tube, vial,

etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

PS:The page price is the reference price, the filling line is a customized product, and the price is subject to the proposal quotation.

Details Images

Pre-sale Service

1. Equipment model selection:

2. According to the special requirements of customers, personalized customized products;

3. Train technicians for customers free of charge;

4. Free professional technical engineers to plan the site on site and design the best process and plan.

5. Acceptance of the product;

6. Assist the client in drafting the construction plan;

Medium-sales Services:

Landpack have the trained team to follow your orders methodically to guarantee the products can be finished

on time with high quality.

After-sales Service

1.One Year Warranty,As long as there is a non-human fault in a year,free re-placement parts.

2.Parts Replacement,Don’t worry about the parts damaged or not sold after the machine is sold.we have a field factory with hundreds of employees to serve you.

3.Engineer Assignment,Lifelong maintain,If your equipment breaks down,we will arrange engineers to repair it.

2. According to the special requirements of customers, personalized customized products;

3. Train technicians for customers free of charge;

4. Free professional technical engineers to plan the site on site and design the best process and plan.

5. Acceptance of the product;

6. Assist the client in drafting the construction plan;

Medium-sales Services:

Landpack have the trained team to follow your orders methodically to guarantee the products can be finished

on time with high quality.

After-sales Service

1.One Year Warranty,As long as there is a non-human fault in a year,free re-placement parts.

2.Parts Replacement,Don’t worry about the parts damaged or not sold after the machine is sold.we have a field factory with hundreds of employees to serve you.

3.Engineer Assignment,Lifelong maintain,If your equipment breaks down,we will arrange engineers to repair it.

4.Online Instruction,We open online services,as long as your equipment failure,our engineers will be the first time for a one-to-one troubleshooting.

5.Feedback Survey,The engineer is required to bring a questionnaire to fill in the satisfaction with the engineer and the use of the equipment.

5.Feedback Survey,The engineer is required to bring a questionnaire to fill in the satisfaction with the engineer and the use of the equipment.

Buyer's Praise

Hot Searches