- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINCHI

-

Model Number:

-

1/4"-12"

-

Outer Diameter:

-

11 - 343 mm

-

factory certificate:

-

ISO9001

-

inspection:

-

ISO BV,CCIC,CIQ or at your option

-

connection:

-

joint or flange

-

technology:

-

extrusion

-

work temperature:

-

-196℃-+420℃

-

color:

-

silver

-

work pressure:

-

1.2MPa-7.5MPa

-

place of origin:

-

HeBei China(mainly production)

-

sample:

-

available

Quick Details

-

Technics:

-

Forged

-

Shape:

-

Round

-

Head Code:

-

Round

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINCHI

-

Model Number:

-

1/4"-12"

-

Outer Diameter:

-

11 - 343 mm

-

factory certificate:

-

ISO9001

-

inspection:

-

ISO BV,CCIC,CIQ or at your option

-

connection:

-

joint or flange

-

technology:

-

extrusion

-

work temperature:

-

-196℃-+420℃

-

color:

-

silver

-

work pressure:

-

1.2MPa-7.5MPa

-

place of origin:

-

HeBei China(mainly production)

-

sample:

-

available

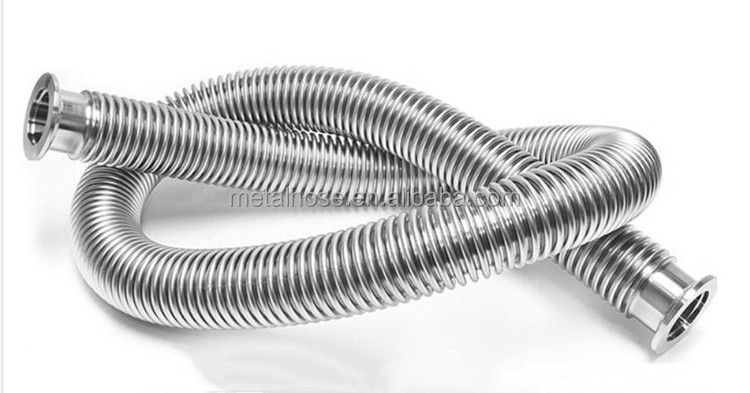

Flexible Vaccum Bellows Hose

XC-Flexible metal Vaccum Bellows Hose

We produce Metal hoses professionally since 1990, there are two wave modes of interlock hose, Annular and Spiral corrugated bellows. Our production line can produce the cargo according to your required parameters.

Details

Production process

1 Steel plate rolling : the steel plate will be thin and we cut them for limited width

2 Rolled round and automatic welding:steel plated rolled to steel pipe,and automatic welding the chink

3 Bellows forming:hydraulic system and mould,it can be pressed out the bellows

4 braided reinforcement:steel wire braided,but usually we have the hose nuts,and we put the metal bellows into the hose nuts.

5 welding:welding the nuts and the hose,welding the hose and the joints

6 pressure test:it must be test,and we can ensure the cooling metal hose 100% no leakage.

Stainless steel vacuum flexible bellow hose

Sunthai's Bellow Hose Is made in food grade SS304,Which alows high vacuum to be obtained With A Large Flow Diameter For Vapors. These Bellow Hoses Are Flexible And Allow The User To Connect A KF Flanged Vacuum Pump To A KF Flanged Vacuum Oven Or Any Other Application like KFX NPT adapters Or KF X Tri-Clamp Fittings.

| Flange Size | KF16,KF20,KF40,KF50,KF80,KF100 |

| End to end length | 50mm to 3000mm(customized) |

| Wall thickness | 0.15 to 0.2mm |

| Surface finish | High mirror polish and |

Features:

1. Soft, flexible, easy to bend, vibration absorbing

2. Helium leakage test before shipping

3.Plastic flange protective cap is included to avoid flange scratching during transportation

4.Delicate Welding to ensure integrity and reliabilityo ensure integrity and reliability

Workshop

0

Packing styles

Application

Transporting Modes

Brief Introduction

Hengshui Xinchi Hose Manufacturing Co.,Ltd (China Metal Hose Factory)

Who located in China(Jinzhou)Rubber and plastic pipe base and f ounded in 1990, 300 employ ee s, the professional and s enior technicians are 100 totally . We have advanced standards for design, mainly produce stainless steel metal hoses, metal bellows, nets, metal& non-metallic compensator polyurethane, high /low pressure hose, hose sheathed insulation, all kind of connectors and other products. Which are widely used in electric power, dock, construction, steel, mining, petroleum, chemical, cement, transportation and other industries of v arious pipes and equipment .

All the product s ha ve passed the ISO9001 international quality system certification.

Using Instruction:

A. When choosing hose, please pay attention to the folloings:

Working environment : working temperature, weather, and the connection with other materials.

Conveyable Matter: Liquid, gasses, solid, mixture of above matters.

Convey ways : delivery matter under the pressure, delivery and suction under vacuum.

Working condition: the pressure and temperature for convying matter, use frquency, impulse and movement.

Installatio n: Bending,vibration of the system, the risk of damaged caused by hitting and friction, application of the right connecting mode.

B. There is limited life for hose assemble;please pay attention that the followings woud reduce the hose useful ife:

a. Making the bend radius smaller than the min bend radius.

b. Twisting, stretching, weld line, squeeze or corrode the hose.

c. To be used exceeded max temperature or lower the min temperature.

d. To be used exceeded the impulse pressure of the max working pressure(the impulse pressure means the rapid rise of pressure).

e. The quality of fitting is not up to the standard and assembling is not well.

C. Requirements for using hose:

a. The pressure(including the impulse pressure)filled in the hose must not be exceeded the max working pressure.

b. Hose can not be used under the temperature not stipulated or suggested including the conveable matter.

c. Hose can not be used under the bend radius that is smaller than the min bend radius stipulated or suggested, or it will block the matter passing, and reduce the hose useful life. The hose should be prevent from twisting or warping around the connection part, because the bending for this part will damage the reinforcement, as a result, the hose will be damaged quickly.

d. The hose can not be used when it is twisted.

e. The edge of hose fitting should be smooth; the size of mandril, sleeve or other accessory must be in confirmed. Less or more control of assembling power will also damage the assembly,.

f. There is a limited life for hose, please check and change it regularly.

Contact Paige

whtaspp:+86-18333708952