- Product Details

- {{item.text}}

Quick Details

-

Glass material:

-

Borofloat33,Corning Eagle Xg , Quartz glass ,Corning Willow glass

-

Glass material2:

-

Soda lime glass, Borosilicate glass

-

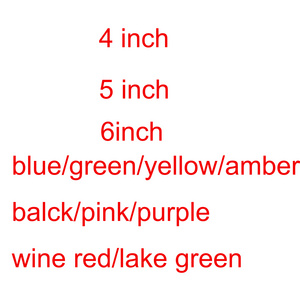

Size:

-

2'' 3'' 4'' 6'' 8'' 12''

-

Light transmission:

-

92%

-

Temperature resistant:

-

550degree C

-

Polishing:

-

Both sides or one side polishing

-

Thcikness:

-

0.1mm 0.2mm 0.3mm 0.5mm 0.7mm

-

Thickness2:

-

0.9mm 1.0mm 1.1mm 2.0mm 3mm 4mm 5mm 6mm 7mm 8mm

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Tking

-

Model Number:

-

Tk012

-

Glass material:

-

Borofloat33,Corning Eagle Xg , Quartz glass ,Corning Willow glass

-

Glass material2:

-

Soda lime glass, Borosilicate glass

-

Size:

-

2'' 3'' 4'' 6'' 8'' 12''

-

Light transmission:

-

92%

-

Temperature resistant:

-

550degree C

-

Polishing:

-

Both sides or one side polishing

-

Thcikness:

-

0.1mm 0.2mm 0.3mm 0.5mm 0.7mm

-

Thickness2:

-

0.9mm 1.0mm 1.1mm 2.0mm 3mm 4mm 5mm 6mm 7mm 8mm

Product Description

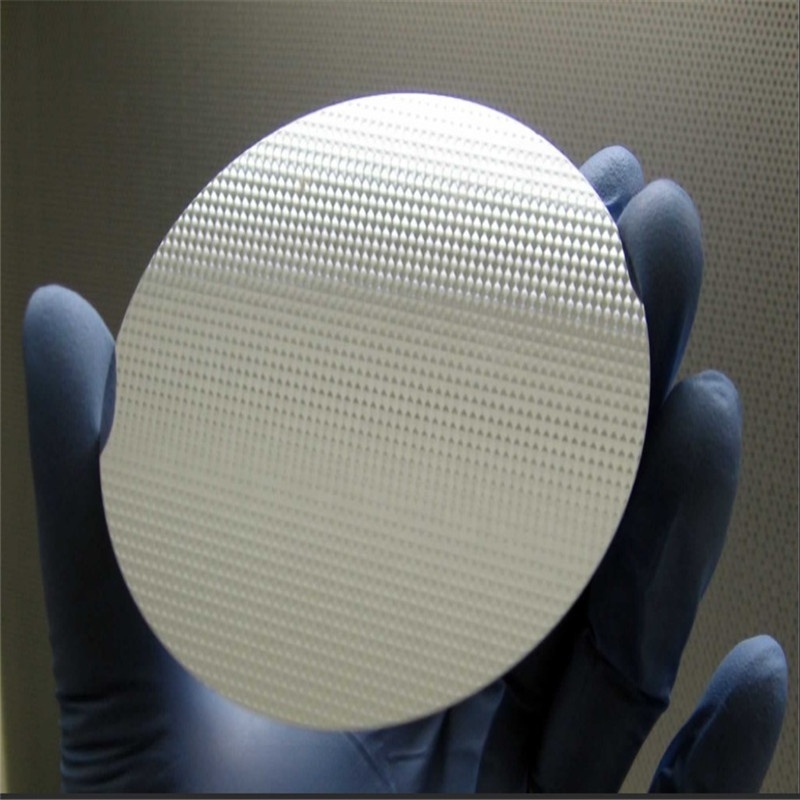

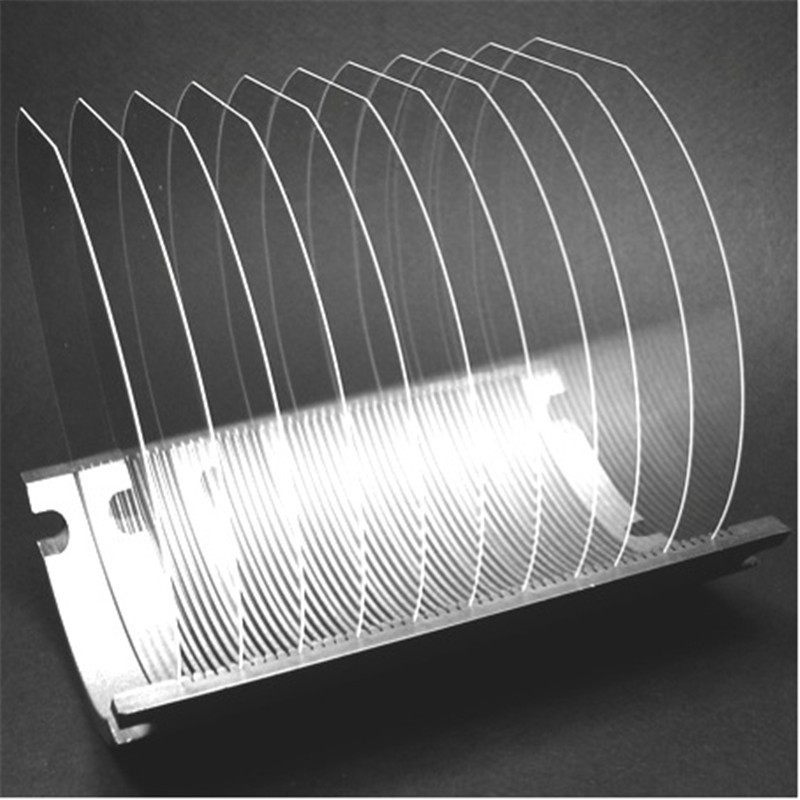

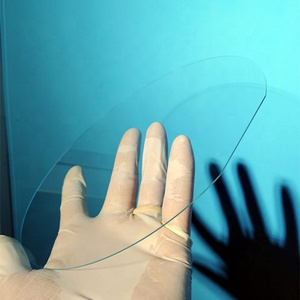

12'' Borosilicate 3.3 substrate glass wafers

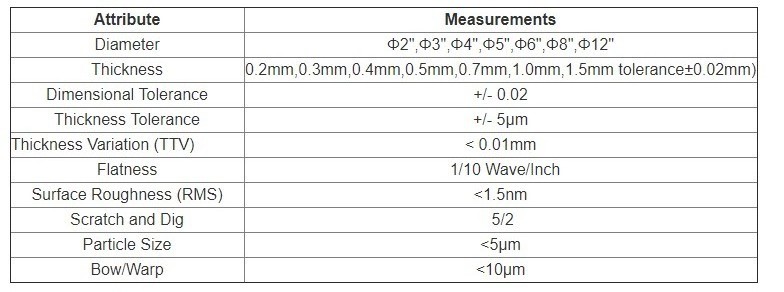

WAFER SPECIFICATIONS

Tking produces wafers to all SEMI Standards including dimensional, flat and notch specifications. In addition, we offer custom specifications designed to your unique needs including, alignment marks, holes, pockets, edge profile, thickness, flatness, surface quality, cleanliness or any other details critical to your application. We also offer these wafers in a broad array of materials including Borosilicate, Aluminosilicate, Fused Silica (instead of quartz), Quartz and Soda Lime.

The following describes the versatility within several of our key processes. For full details on the process, please contact us freely get more information.

WAFER FABRICATION PROCESS

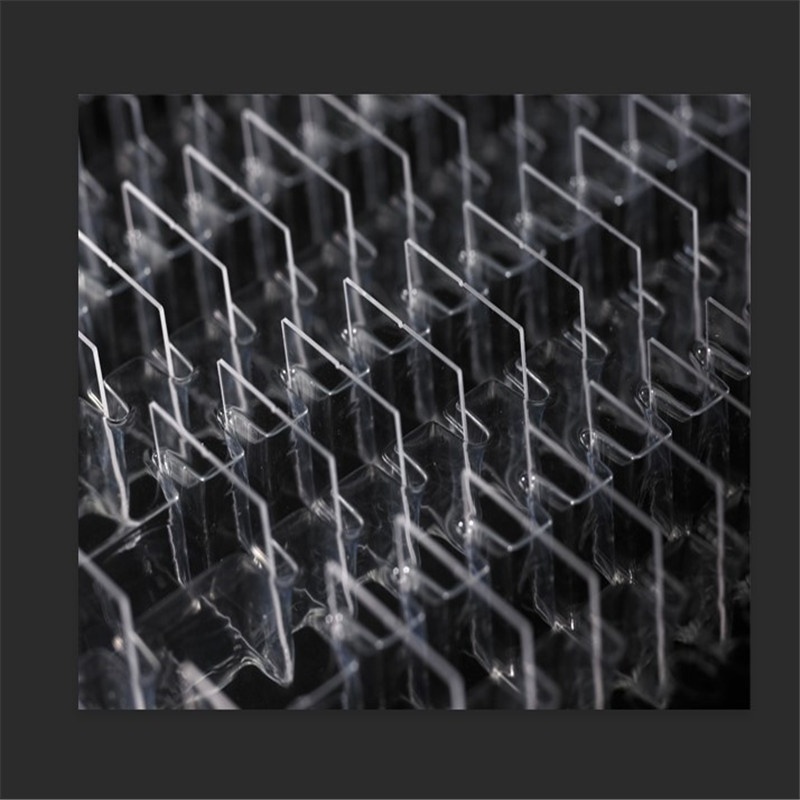

Shape Cut

Thin sheets are scribed, thick sheets are water jetted and blocks are wire sawn to begin the process with a wafer "blank".

CNC Edge

Each wafer is individually edged on a Precision CNC Edge Grinding Station.

Lapping

As required, wafers are lapped to precise thickness or flatness.

Polishing

Double-side Commercial Polish removes subsurface damage and Super Polish creates a pristine finish.

Cleaning

We combine ultrasonics and megasonics on multiple cleaning lines which feed directly into a Class 100 Clean Room.

Inspection

In our Class 100 Optical Clean Room, we inspect to various quality levels under the appropriate lighting conditions.

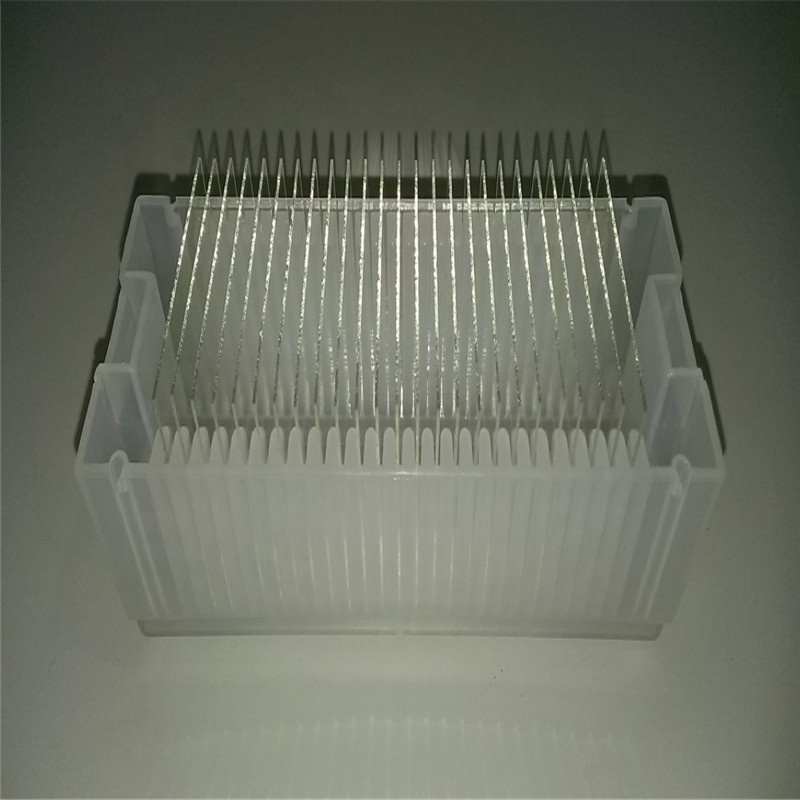

Packaging

All wafers are packed in pre-cleaned containers, double bagged and vacuum sealed within the Class 100 Clean Room.

Tking produces wafers to all SEMI Standards including dimensional, flat and notch specifications. In addition, we offer custom specifications designed to your unique needs including, alignment marks, holes, pockets, edge profile, thickness, flatness, surface quality, cleanliness or any other details critical to your application. We also offer these wafers in a broad array of materials including Borosilicate, Aluminosilicate, Fused Silica (instead of quartz), Quartz and Soda Lime.

The following describes the versatility within several of our key processes. For full details on the process, please contact us freely get more information.

WAFER FABRICATION PROCESS

Shape Cut

Thin sheets are scribed, thick sheets are water jetted and blocks are wire sawn to begin the process with a wafer "blank".

CNC Edge

Each wafer is individually edged on a Precision CNC Edge Grinding Station.

Lapping

As required, wafers are lapped to precise thickness or flatness.

Polishing

Double-side Commercial Polish removes subsurface damage and Super Polish creates a pristine finish.

Cleaning

We combine ultrasonics and megasonics on multiple cleaning lines which feed directly into a Class 100 Clean Room.

Inspection

In our Class 100 Optical Clean Room, we inspect to various quality levels under the appropriate lighting conditions.

Packaging

All wafers are packed in pre-cleaned containers, double bagged and vacuum sealed within the Class 100 Clean Room.

Detailed Images

Certifications

Contact us

Tel:86+13414986564

Skype : yinhuanspring

Sales manager:Spring Lin

.

Hot Searches