Zhangjiagang Chinafor Machinery Co., Ltd. is always specialized in waste briquetting machines for various waste EPS, EPP, EPE,XPS,PUR, PSP, cans, films and bottles. We produce a wide range of waste recovery compressors. All compressors produced by Chinafor

Machinery are produced in Qinfeng's own factory in Zhangjiagang,China.

- Product Details

- {{item.text}}

Quick Details

-

Control System:

-

Touch Screen+PLC

-

Capacity:

-

80-100kg/h

-

Name:

-

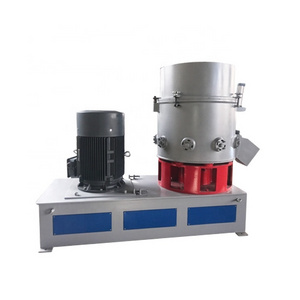

Professinal product plastic melter

-

Colour:

-

Optional

-

Power:

-

29.4KW

-

Plastic Type:

-

EPS,EPE,EPP

-

Material:

-

Carbon Steel

-

Final product:

-

hot melted ingot

-

Color:

-

Optional

-

Product name:

-

EPS recycled hot melter

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Chinafor

-

Certification:

-

CE,Certificate of low noise

-

Control System:

-

Touch Screen+PLC

-

Capacity:

-

80-100kg/h

-

Name:

-

Professinal product plastic melter

-

Colour:

-

Optional

-

Power:

-

29.4KW

-

Plastic Type:

-

EPS,EPE,EPP

-

Material:

-

Carbon Steel

-

Final product:

-

hot melted ingot

-

Color:

-

Optional

-

Product name:

-

EPS recycled hot melter

Product Description

Plastic melter densifier Working Principle:

The twin shaft crushing blades are two parallel blades shaft with different rotation direction , each blade shaft has 18 blades and driven by the gear box to crush material that will be conveyed to the barrel through the screen. The material will be sent by the high speed rotary screw to the heating barrel. Then they will be melted under high temperature extruded to expected sharps.

EPS recycled hot melter Crusher technical :

The tilted feeding hopper is easy to put the EPS material in,and the material won't be pushed out during the crushing process.

The plastic recycling machine use twin shaft crushing blades, two parallel blade shafts symmetrically fixed with blade,the blade on the two blade shafts is dislocation arrangement, and the blade of each shaft is evenly arranged in the axis of the knife with arithmetic point of view in the same direction. The first blade and the last blade of each shaft has a 90°angle.

The plastic recycling machine use twin shaft crushing blades, two parallel blade shafts symmetrically fixed with blade,the blade on the two blade shafts is dislocation arrangement, and the blade of each shaft is evenly arranged in the axis of the knife with arithmetic point of view in the same direction. The first blade and the last blade of each shaft has a 90°angle.

Plastic melter Features:

1,Twin shaft crushing blades, this hot melting machine adopts manual feeding, the material will be crushed by the twin shaft blades and conveyed to the barrel of the main machine through the screen.

2,The screw of the main machine can convey the heating the material to melt condition ,then extrude them and hydraulic blade cut them to pieces for easy storage and transportation.

3,The shape of the products can be designed according to customers' requirement.

2,The screw of the main machine can convey the heating the material to melt condition ,then extrude them and hydraulic blade cut them to pieces for easy storage and transportation.

3,The shape of the products can be designed according to customers' requirement.

Product Paramenters

EPS recycled hot melter CF-HM 200

The following sizes are for reference and special requirements can be discussed in detail.

|

Model

|

CF-HM-200 plasatic melter densifier

|

|

Screw diameter

|

φ197 mm

|

|

Screw distance

|

150 mm

|

|

Screw speed

|

110 r/min

|

|

Capacity

|

100~120Kg/h

|

|

Extrusion center height

|

326 mm

|

|

Motor power

|

15KW

|

|

Crusher motor power

|

2.2kwx2

|

|

Heating power

|

10kw

|

|

Crusher blades quantity

|

2Sets 9sets+10sets

|

|

Crusher rotation speed

|

100r/m

|

|

Size L×W×H

|

2800×1580×1950

|

Working Process:

Advantages.

1. Lower noise——machine drives by gearbox,not the belts.

2.Safe——There is a protective cover at the outlet;The inlet height is in accordance with safety standards;The reducer drives the machine to operate safely and efficiently,And there is emergency stop and the overload switch in the control system.

3.Have nice after-sale service——Provide installation and debugging if the customer needs;12 months warranty.

4.Cost-effective——We offer the customer good quality machines, but in a very reasonable price.

5.Long life——After one year , we will serve the customer continually and the machine can running well for a long time. Our first machine is still running well now.

6.Optional Electrical elements——Inverter(when install inverter,it can deal with different type material:EPS,EPP,EPE.) and the other elements we can set in the machine according to the customer’s requirement.

2.Safe——There is a protective cover at the outlet;The inlet height is in accordance with safety standards;The reducer drives the machine to operate safely and efficiently,And there is emergency stop and the overload switch in the control system.

3.Have nice after-sale service——Provide installation and debugging if the customer needs;12 months warranty.

4.Cost-effective——We offer the customer good quality machines, but in a very reasonable price.

5.Long life——After one year , we will serve the customer continually and the machine can running well for a long time. Our first machine is still running well now.

6.Optional Electrical elements——Inverter(when install inverter,it can deal with different type material:EPS,EPP,EPE.) and the other elements we can set in the machine according to the customer’s requirement.

Detailed Images

Related Products

Packing&Shipping

FCL

delivery, directly wrap film package packing;

LCL , wrap with wrapping film first, then pack in wooden case, the wooden case is fumigation-free, in line with export requirements.

(The equipment can be packaged according to customer's requirement)FOB Shanghai

LCL , wrap with wrapping film first, then pack in wooden case, the wooden case is fumigation-free, in line with export requirements.

(The equipment can be packaged according to customer's requirement)FOB Shanghai

After Sales Service

Company Introduction

Zhangjiagang Chinafor Machinery Co.,Ltd is located near the “Golden Waterway of the YangTze River” in the city of ZhangJiaGang,two hours drive from ShangHai Pudong

International Airport.Zhangjiagang Chinafor Machinery Co.,Ltd is a professional manufacturer and trader specializing in EPS recycling machinery,Plastic Mixing,Plastic Bottle Recycling,Plastic Extruder,Plastic Shredders ,we producting many types of recycling machine for waste recycling.Our boss has been a mechanical engineer for over twenty years.

International Airport.Zhangjiagang Chinafor Machinery Co.,Ltd is a professional manufacturer and trader specializing in EPS recycling machinery,Plastic Mixing,Plastic Bottle Recycling,Plastic Extruder,Plastic Shredders ,we producting many types of recycling machine for waste recycling.Our boss has been a mechanical engineer for over twenty years.

Chinafor Machinery is the leading on the market for the waste compactors, with the extensive knowledge and experience, we continuous development the compactor machine for waste materials and export to different countries.

Zhangjiagang Chinafor Machinery Co.,Ltd Warmly welcome you visit and let’s make the win-win cooperation to build a good future for the earth.

Hot Searches