- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DINGCHEN MACHINERY

-

Voltage:

-

380/440v

-

Power:

-

300KW

-

Dimension(L*W*H):

-

30*6.5*5METER

-

Weight:

-

120 kg

-

Name:

-

Paper Recycling Machine

-

Output paper:

-

Testliner and Fluting Paper

-

Raw material:

-

Waste Carton

-

Forming Type:

-

Cylinder mold

Quick Details

-

Production Capacity:

-

20T/Day

-

Product Type:

-

paper making machine

-

Processing Type:

-

waste paper recycling

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DINGCHEN MACHINERY

-

Voltage:

-

380/440v

-

Power:

-

300KW

-

Dimension(L*W*H):

-

30*6.5*5METER

-

Weight:

-

120 kg

-

Name:

-

Paper Recycling Machine

-

Output paper:

-

Testliner and Fluting Paper

-

Raw material:

-

Waste Carton

-

Forming Type:

-

Cylinder mold

Products Description

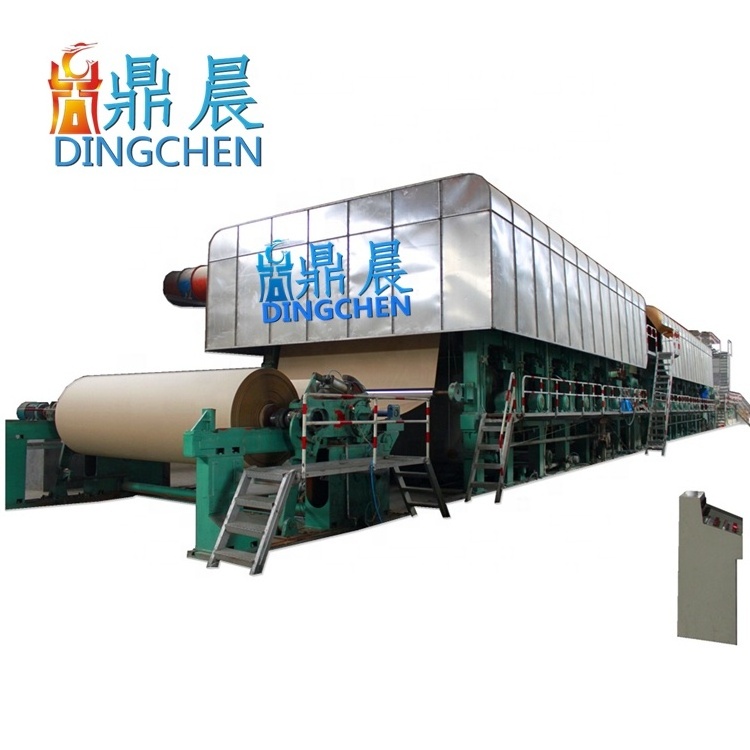

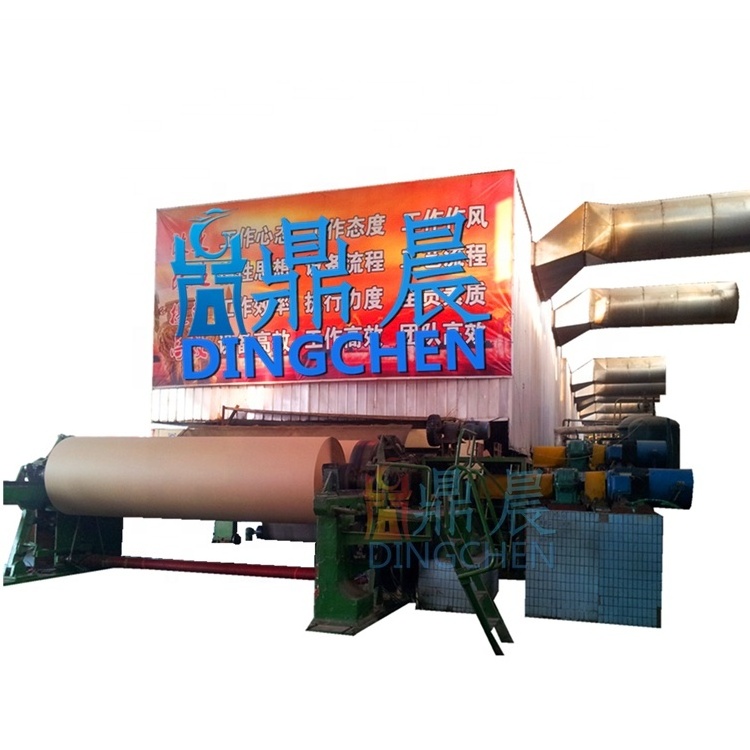

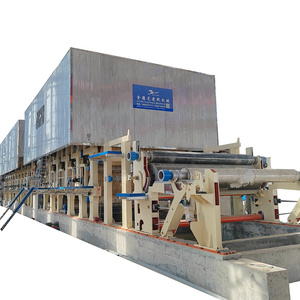

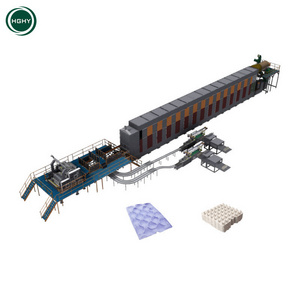

2000mm Type 20Tons Multi Dryer Cylinder & Multi Cylinder Mold Carton Paper Machine

Product Paramenters

2000MM 20TPD Fluting Paper Making Machine

Technical parameter:

1. Raw material:Waste carton;OCC

2. Output paper: Kraft liner paper,fluting paper,corrugated paper

3.Output paper weight: 100-200g/m2

4. Output paper width: 2000mm

5. Capacity: 20T/D

6. Drive way: A/C inverter speed control, sectional drive.

|

No.

|

Item

|

Function

|

||

|

Stock preparation section

|

|

|

||

|

1

|

D type Hydra-pulper

|

To break the waste paper into pulp and drop down the impurity and pins

|

||

|

2

|

High density pulp cleaner

|

To separate and sieve the small stone,staples,heavy impurity in the pulp

|

||

|

3

|

Fiber separator

|

To beating pulp again and separate long and short fiber

|

||

|

4

|

Vibrating screen

|

To separate and remove the small impurity(such as broken plastic tape,foam,etc)

|

||

|

5

|

Pulp refiner

|

To grind pulp fiber

|

||

|

6

|

Low concentration pulp cleaner

|

To remove the sand and tiny impurity in the water and pulp

|

||

|

7

|

Pressure screen

|

To screening pulp fiber

|

||

|

8

|

Impeller

|

To stir the pulp and make sure the pulp and water mixed well

|

||

|

9

|

Pulp pump

|

To provide the pulp for the needed machine

|

||

|

Paper making section

|

|

|

||

|

10

|

Cylinder mold part

|

To forming wet paper web

|

||

|

11

|

Vacuum dewatering part

|

To absorb the water in the wet paper

|

||

|

12

|

Press part

|

To dewatering by mechanical gravity press force

|

||

|

13

|

Dryer section part

|

To dry wet paper

|

||

|

14

|

Winding part

|

To reeling output paper be a jumbo paper roll

|

||

|

15

|

Paper rewinding part

|

To rewind the jumbo roll paper to different size (width&diameter) according to your requirement

|

||

|

Boiler section

|

|

|

||

|

16

|

Gas/diesel/coal boiler

|

To provide high temperature and pressure steam to dryer to dry paper

|

||

Details Images

Product packaging

Hot Searches