- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

AT ceramic

-

Density:

-

5.95 g/cm3

-

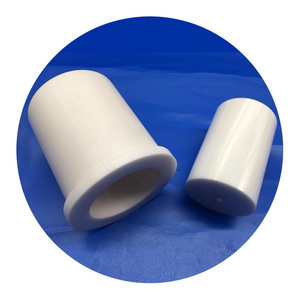

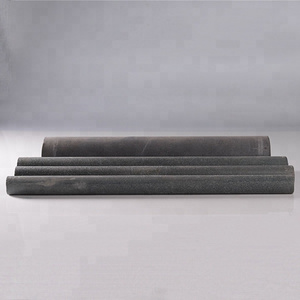

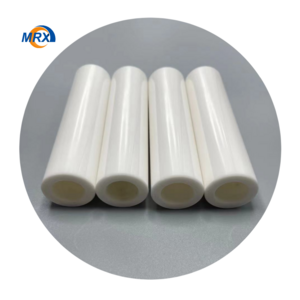

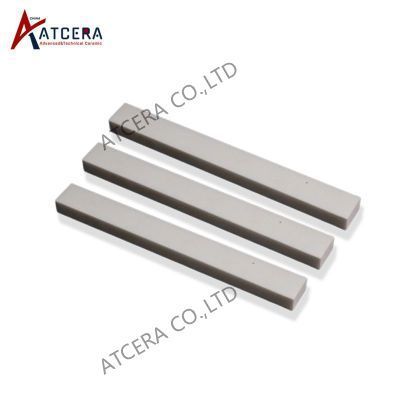

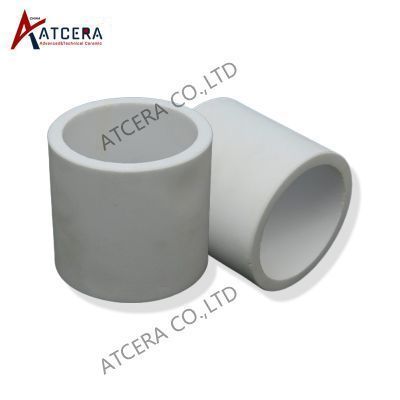

Item:

-

zro2 ceramic tube/rod

-

material:

-

Zirconia Ceramic

-

Working Temperature:

-

2200℃

-

Feature:

-

insulation , wear resistance

-

Color:

-

Ivory White Yellow Pink

-

Shape:

-

Customer's Design

Quick Details

-

Material:

-

Zirconia Ceramic

-

Place of Origin:

-

Hunan,China

-

Model Number:

-

AT ceramic

-

Brand Name:

-

AT ceramic

-

Density:

-

5.95 g/cm3

-

Item:

-

zro2 ceramic tube/rod

-

material:

-

Zirconia Ceramic

-

Working Temperature:

-

2200℃

-

Feature:

-

insulation , wear resistance

-

Color:

-

Ivory White Yellow Pink

-

Shape:

-

Customer's Design

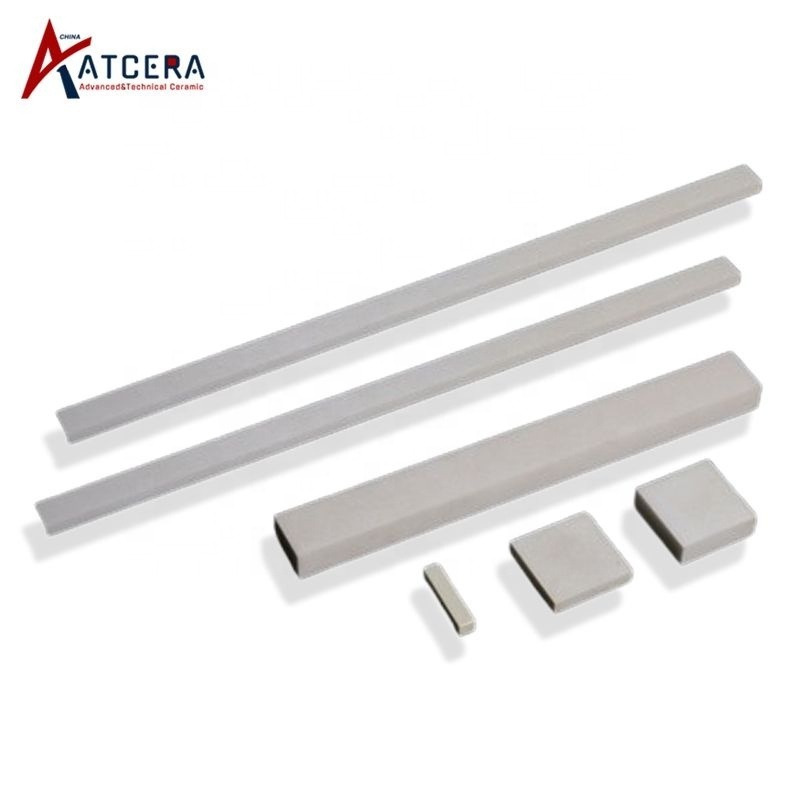

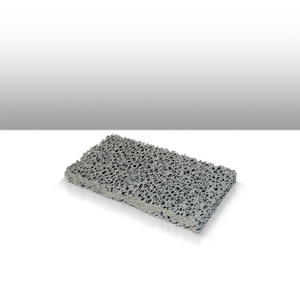

Zirconia Ceramics, or zirconium dioxide ceramics, are exceptionally strong technical ceramic materials with excellent hardness, toughness, and corrosion resistance without the brittleness common to other ceramic materials. There are several grades of zirconia ceramics, with yttria and magnesia partially stabilized zirconia ceramics being the most common.

Each stabilized zirconia provides unique and specific properties that meet the demands of extreme applications found in many industries, they perform in operating environments that plastics, metals and other ceramic materials cannot withstand. Typical applications include structural components, bushings, pistons, sleeves, rollers, guides, insulators, and more.

|

Ceramic Properties

|

|

|

|

|

|

|

||||||

|

Item

|

Unit

|

99%Al2O3

|

ZrO2

|

AIN

|

Si3N4

|

SiC

|

||||||

|

Density

|

g/cm3

|

3.9

|

6

|

3.23

|

3.2

|

3.2

|

||||||

|

Gas permeability

|

|

0

|

0

|

0

|

0

|

0

|

||||||

|

Water Absorption

|

|

0

|

0

|

0

|

0

|

0

|

||||||

|

Flexural Strength

|

Mpa

|

340

|

1000

|

400

|

1000

|

/

|

||||||

|

Compressive Strength

|

Mpa

|

3600

|

3000

|

3500

|

3600

|

2000

|

||||||

|

Modulus of Elasticity

|

Gpa

|

380

|

200

|

380

|

300

|

410

|

||||||

|

Impact Resistance

|

Mpa.m1/2

|

5.1

|

6

|

4

|

7

|

4

|

||||||

|

Vickers Hardness

|

HVO.5

|

1650

|

1200

|

1650

|

1600

|

2000

|

||||||

|

Thermal Conductivity

|

W/mk

|

27

|

< 2

|

260

|

30

|

70

|

||||||

|

Highest Application Temperature

|

°C

|

1750

|

1050

|

2200

|

1300

|

1300

|

||||||

|

Volume resistivity(20°C)

|

Ohm/cm2

|

>1014

|

>1013

|

>1014

|

>1014

|

>1015

|

||||||

|

Dielectric breakdown strength

|

KV/mm

|

25

|

17

|

25

|

20

|

20

|

||||||

|

Dielectric Constant

|

1MHZ

|

9.5

|

30

|

8

|

9

|

/

|

||||||

|

Thermal Expansion(25-1000°C)

|

1X10-6/℃

|

5.4-8.3

|

10

|

4.0-6.0

|

3

|

4.5

|

||||||

Hunan Atcera CO. Ltd. has been deeply engaged in the field of advanced ceramics for 12 years, and has production experience of more than 2000 precision ceramic products. We focus on the material of alumina ceramics, aluminum nitride ceramics, zirconia ceramics, silicon carbide ceramics, boron carbide ceramics, silicon nitride ceramics, boron nitride ceramics, quartz, etc., and aim to provide you with advanced ceramics one-stop service.We have been offering our products and services to our clients from more than 100 countries or regions.

Hot Searches