- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

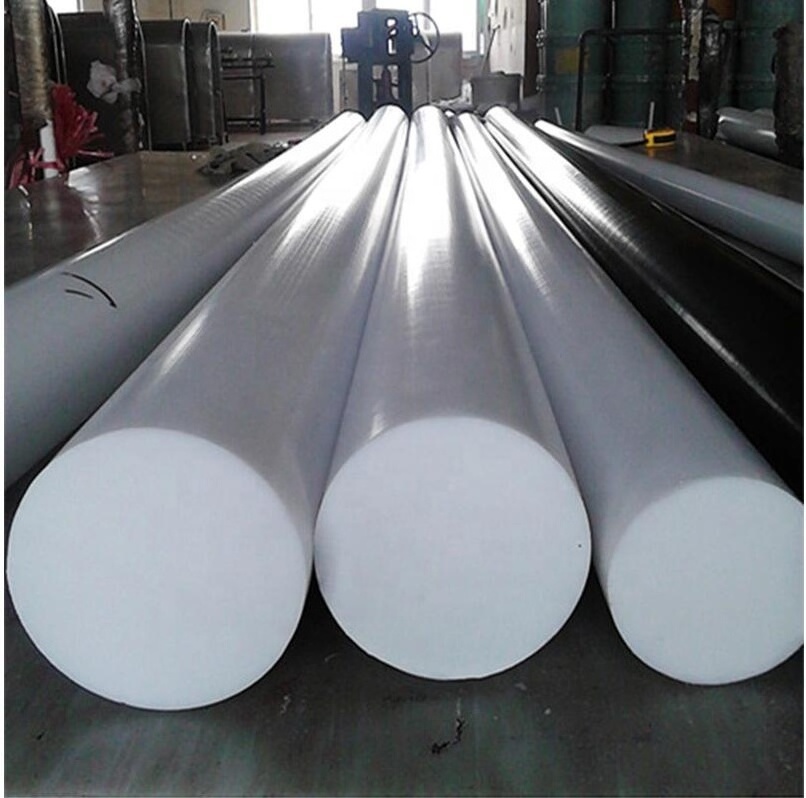

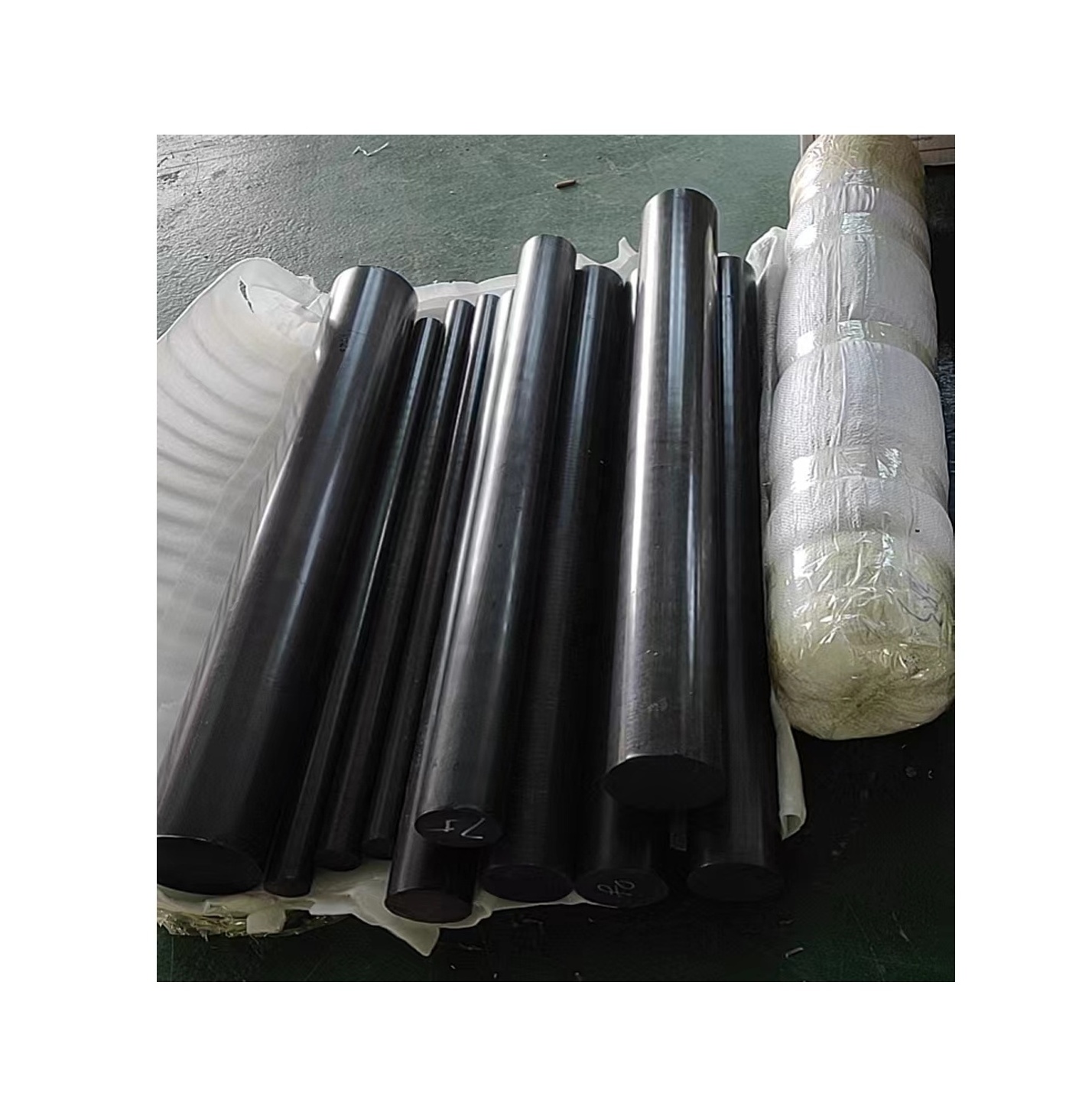

PTFE Rod

-

Appearance density g/cm3:

-

2.10-2.30

-

Tensile strength (min) MPa:

-

18

-

Crack elongation (min) %:

-

230

-

processing:

-

Extruded/Molded

-

diameter mm:

-

1- 500 mm

-

Length:

-

customize

-

hardness shore:

-

65-70

-

working temperature:

-

-180-+270

-

Electric strength:

-

≥10 kv/mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZhaoNM

-

Model Number:

-

ZT-PTFERD02

-

Product name:

-

PTFE Rod

-

Appearance density g/cm3:

-

2.10-2.30

-

Tensile strength (min) MPa:

-

18

-

Crack elongation (min) %:

-

230

-

processing:

-

Extruded/Molded

-

diameter mm:

-

1- 500 mm

-

Length:

-

customize

-

hardness shore:

-

65-70

-

working temperature:

-

-180-+270

-

Electric strength:

-

≥10 kv/mm

Product Description

|

Filled PTFE products have strong corrosion resistance and friction-resistance,By adding filler such as glass fiber,carbon fiber,copper powder,graphite,asbestos,MOS2,AL2O3,carbon powder,ceramic fiber,metal powder,polyamide,PS,the hardness,compression strength and abrasion resistance of the products is improved ,in addition,it will have good heat conductivity and low heat expansion coefficient. |

|

|

Glass Fiber: |

Increases compressive strength, rigidity and wear. |

|

|

Reduces creep and cold flow |

|

|

Minimal effect on chemical and electrical properties |

|

Carbon: |

Increases compressive strength, hardness, wear, and load properties. |

|

|

Good chemical resistance |

|

|

Various types and amounts of carbon can be added to alter conductivity |

|

Graphite: |

Reduces coefficient of friction |

|

|

Reduces initial wear |

|

|

Increases strength |

|

Molybdenum Disulfide: |

Increases hardness, stiffness, and wear |

|

|

Minimal effect on chemical and electrical properties |

|

Bronze: |

Increases hardness and wear resistance |

|

|

Increases dimensional stability and compressive strength |

Types and Specifications

|

Type |

Diameter(mm) |

Length(mm) |

|

PTFE Extruded Rod |

1~ 500 |

1000,2000,3000

|

|

PTFE Molded Rod |

180,200,250,270,300,350,400,500,600 |

100-500 |

|

No |

Filled Compound And Content By Wt |

Tensile Strength Mpa |

Ultimate Strength% |

Shrinkage |

|

1 |

20% glass fiber |

16±3 |

300±50 |

2.0-3.0 |

|

2 |

25% glass fiber |

15±3 |

250±50 |

1.5-2.5 |

|

3 |

15%glass fiber 5%graphite |

18±3 |

250±50 |

1.6-2.6 |

|

4 |

60%bronze |

19±3 |

150±50 |

1.5-2.5 |

|

5 |

15%carbon fiber |

19±3 |

250±50 |

2.0-3.0 |

|

6 |

25%carbon fiber |

18±3 |

150±50 |

1.6-2.6 |

|

7 |

15%graphite |

20±3 |

200±50 |

1.8-2.8 |