- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V (adjustable)

-

Dimension(L*W*H):

-

custom made

-

Weight (T):

-

5 T

-

Power (kW):

-

120

-

After-Sales Service:

-

1 year

-

Chamber material:

-

Cast iron, stainless steel, optional

-

Structure:

-

Horizontal, vertical, batch, continuous

-

Loading capacity:

-

3000kg (adjustable)

-

Vacuum system:

-

Leybold, EVP, Edwards, Kinney

-

Heating method:

-

resistance, induction

-

PLC controller:

-

SIEMENS, MITSUBISHI, LG

-

Heater:

-

Mo belt, Tungsten, Graphite, SiMo, SiC

-

Max temperature:

-

500C - 1800C (custom made)

-

Temperature uniformity:

-

±5 C

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

SIMUWU

-

Voltage:

-

380V (adjustable)

-

Dimension(L*W*H):

-

custom made

-

Weight (T):

-

5 T

-

Power (kW):

-

120

-

After-Sales Service:

-

1 year

-

Chamber material:

-

Cast iron, stainless steel, optional

-

Structure:

-

Horizontal, vertical, batch, continuous

-

Loading capacity:

-

3000kg (adjustable)

-

Vacuum system:

-

Leybold, EVP, Edwards, Kinney

-

Heating method:

-

resistance, induction

-

PLC controller:

-

SIEMENS, MITSUBISHI, LG

-

Heater:

-

Mo belt, Tungsten, Graphite, SiMo, SiC

-

Max temperature:

-

500C - 1800C (custom made)

-

Temperature uniformity:

-

±5 C

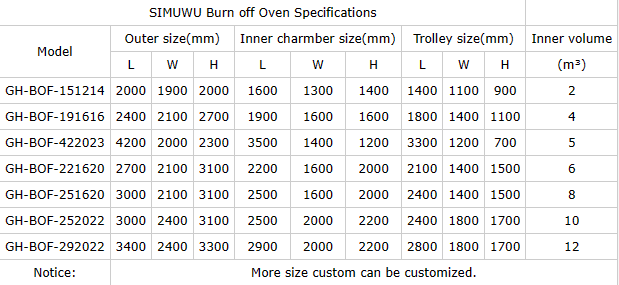

Products Description

More furnace as below for your choice!

|

FURNACE NAME

|

Model

|

Application

|

Decription

|

|

Vacuum Heat Treatment Furnace

|

(1) RVGQ-series Gas Quencing

(2) VOGQ-series Oil Quencing (3) RVA-series Annealing (4) RVT-series Tempering (5) RVC-series Vacuum Carburizing (6) RVN-series Nitriding (7) RVN-T-series PIT Gas Nitriding (8) GH-GCF-series Gas Carburizing |

Mould steel

High speed steel. H13 HSS D2 Inconel Stainless steel Other material |

Max Temp:1350℃

Temp Uniformity: ±3℃or±5℃ Ultimate vaccum:6.67x10-3Pa(custom made) Gas pressure:6/10/15/20Bar |

|

Vacuum Sintering Furnace

|

(1) RVS-series Sintering Furnace

(2) IVS-H Induction Sintering (3) CDF-series Catalytic debinding (4) RVS-S-Series SIC Sintering (5) RVS-D-series Debinding&Sintering |

MIM parts

PM parts CIM parts Silicone carbide SIC B4C NdFeB Titanium Tungsten carbide Other material |

Max Temp:1200-2400℃

Temp Uniformity:±3℃or±5℃ Ultimate vaccum:6.67x10-3Pa (custom made) Gas:Ar/N2/H2(Optional) |

|

Vacuum Brazing Furnace

|

(1)RVB-series Low temperature brazing

(2)RHVB-series High temperature brazing (3)RVB-AL aluminum brazing |

Glass brazing

Bar-plate, tube fin aluminum heat exchanger Stainless steel Copper PCD,PCBN,CVD Other material |

Max Temp:850-1300℃

Temp Uniformity:±3℃or±5℃ Ultimate vaccum:6.67x10-3Pa (custom made) Gas:Ar/N2/H2(Optional) |

|

Non-Standard Vacuum Equipment

|

Custom made

|

More materials

|

Custom made according to your requirement

|

Packaging & Shipping

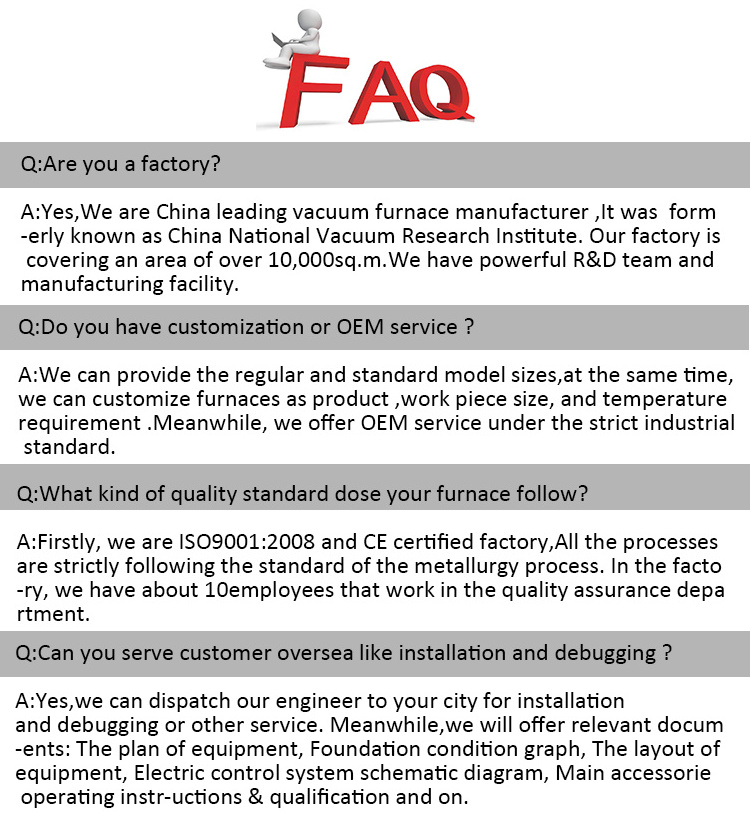

FAQ

Related Products

Click on the image for more related products

Hot Searches