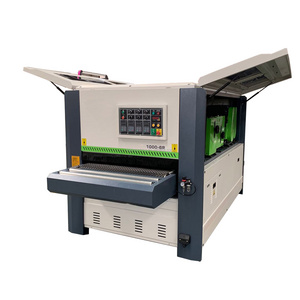

The large sanding roller is composed of several brushes and sanding belt, and the overall

swing is left and right for sanding

.The sanding effect of the

transverse

groove is obvious.

- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

13.58KW

-

Max.width of workpiece:

-

1300mm

-

Min.length of workpiece:

-

400mm

-

Max.depth of workpiece:

-

100mm

-

Height of working table:

-

850mm

-

Feeding speed:

-

0~10m

-

Working power supply:

-

380V 50HZ

-

Total power:

-

13.58kw

-

Dimension:

-

4200x2100x2200mm

-

Weight:

-

3200kg

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KAIYUANJINGKE

-

Weight (KG):

-

3200 KG

-

Power (kW):

-

13.58KW

-

Max.width of workpiece:

-

1300mm

-

Min.length of workpiece:

-

400mm

-

Max.depth of workpiece:

-

100mm

-

Height of working table:

-

850mm

-

Feeding speed:

-

0~10m

-

Working power supply:

-

380V 50HZ

-

Total power:

-

13.58kw

-

Dimension:

-

4200x2100x2200mm

-

Weight:

-

3200kg

The abrasive of the grinding roller

can be freely combined (

DuPont wire, abrasive cloth strip

) to polish the uneven

profile and corners of the plate.

Double row disc sand

Speed conversion speed regulation,

independent lifting control

, convenient

replacement, transfer and vibration movement for sanding, can sanding any profiled surface and corner.

AIl operation interface,

data touch operation

, with remote assistance device program and parameter function.

Body frame

The Body frame makes the whole machine more

stable and balanced

, can carry more parts and protect the whole machine.

Lower polishing roller

The lower polishing roller is used

to sand the

bottom

surface of the plate to make the effect more perfect

Vacuum adsorption air outlet

When conveying the small plate, the

adsorption table can absorb the small plate and then smoothly pass through the sanding parts, mainly to extract the air inside the conveying table to form an air flow, and then

absorb the sanded dust to the outside.

This equipment is equipped with

an

automatic feeding system

, a PLC program memory one-key control sytem, and a flexible combination of multi-component sand heads. It is applicable to the white body of various

flat, profiled surfaces,

curved surfaces and other plates, and the paint can be sanded and polished.

|

Machine model

|

MSG1300- P2A2C4

|

|

Maximum width of workpiece

|

1300mm

|

|

Minimum sanding length

|

380mm

|

|

Maximum Sanding thickness

|

0~100 mm

|

|

Feeding speed

|

0~10 m/min

|

|

Table height

|

860mm

|

|

Conveying motor power

|

2.2Kw

|

|

Power of transverse sand motor of sand roller

|

4 sets of 1.5kw

|

|

Power of disc motor

|

1 set 1.5kw

|

|

Motor power of lifting pressure roller

|

0.37kw

|

|

Swing motor power

|

4 sets 0.37kw

|

|

Total power

|

14.5 KW

|

|

Dimension

|

3850x2230x2050 mm

|

|

Weight

|

3800KG

|

Q1. Are your trading company or factory?

A1. We are

factory

with more than

5000m2 workshop

located in Yucheng Middle Road, Xichong, Lunjiao Town, Shunde Dist., Foshan, Guangdong, China.

Q2. What machine can you supply?

A2. Our main machines are Wide Brush Profile sander, Flat Surface Sander, Linear sander, Straight/Arc Edge Sander, UV Vacuum Edge Spraying Sander, various sol-id wood sanders etc.

widely used for furniture production.

Q3. What is the payment term?

A3.

T/T 30%

in advance and

balance before shipment, LC

or by negotiation.

Q4. What is the delivery time?

A4. Normal 380V voltage is

15-30 days

, other voltage is

30-45days, 40-60 days

for non-standard customized equipment.

Q5. What is the guarantee?

A5.

12 months for

the whole machine. Within

12 months

of normal use and maintenance, if the machine has problems,

replace the parts free of charge

. More t-han 12 months, parts need to be purchased. You will also receive lifelong technical

support and services.

Q6. Can you support the pre-sales service before confirm the order?

A6. Yes , you will receive the support of

experienced pre-sales engineers,

including not only the selection of machines and auxiliary equipment, but also the electrical, pneumatic, and machine layout in the factory.

The factory can provide customers with production line planning drawings for free.

Hot Searches