- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4600x2500x1800

-

Weight:

-

5000 KG

-

Product Name:

-

10000-18000 GS Flat Magnetic Iron Remover

-

Magnetic Panel Width:

-

2000mm

-

Magnetic Panel Length:

-

2500mm

-

Magnetic Intensity:

-

15000GS

-

MOQ:

-

1 Set

-

Price:

-

Negotiation before order

-

Quality:

-

Excellent & Chinese Standard

-

Max feeding size:

-

≤3mm

-

HS Code:

-

84741000

-

Keywords:

-

Flat Magnetic Separator,Wet Magnetic Separator,Iron Magnetic Separator

Quick Details

-

Production Capacity:

-

90%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

HengHong Flat Magnetic Iron Remover

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4600x2500x1800

-

Weight:

-

5000 KG

-

Product Name:

-

10000-18000 GS Flat Magnetic Iron Remover

-

Magnetic Panel Width:

-

2000mm

-

Magnetic Panel Length:

-

2500mm

-

Magnetic Intensity:

-

15000GS

-

MOQ:

-

1 Set

-

Price:

-

Negotiation before order

-

Quality:

-

Excellent & Chinese Standard

-

Max feeding size:

-

≤3mm

-

HS Code:

-

84741000

-

Keywords:

-

Flat Magnetic Separator,Wet Magnetic Separator,Iron Magnetic Separator

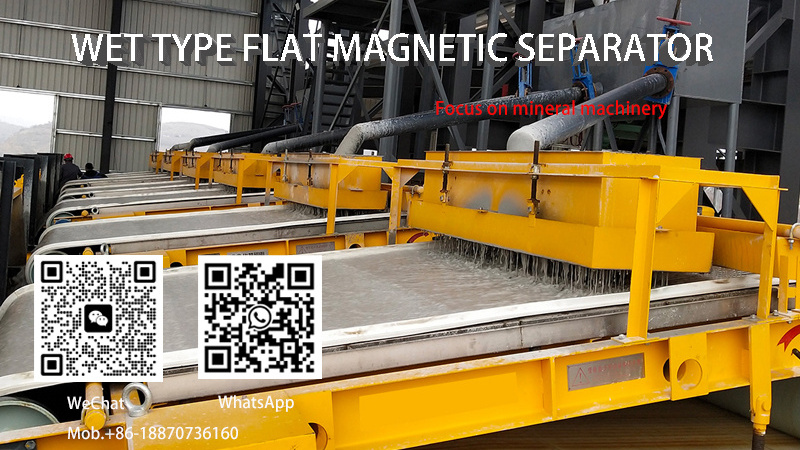

China Top Supplier Magnetic Separation Machine Manganese Silica Sand Quartz Feldspar 10000-18000 GS Flat Magnetic Iron Remover

Jiangxi Henghong mining machinery is devoting to provide turnkey solution with worldwide clients for mineral processing plant including research, design, manufacture,installation and commissioning, personnel training, after-sale service and management of processing plant. Up to now, we have developed six major product lines: they are mining crushing machine, mining milling machine,mining classifying separator, mining flotation machine ,mining magnetic separation machine and the mining gravity separator. When you find us, you find one best mining machinery manufacturer.

Flat Plate Magnetic Separator

High filed strength magnetic flat type magnetic separator is our latest research and development of high gradient and high intensity magnetic separator equipment.

It is mainly used to 1.2 mm fine minerals, such as the weakly magnetic ore and remove the iron impurities from the non-metallic ore, such as mica powder, quartz sand, potassium, feldspar, nepline, fluorite, sillimanite, spodumene,kaoline, manganese ore, weak magnetite,pyrrhotite, calcined ore, ilmenite,hematite, limonite, siderite, chromite, wolframite, columbite-tantalite, red mud. It also can be used in iron-removal operation of coal, non-magnetic ore and building materials etc.

It is mainly used to 1.2 mm fine minerals, such as the weakly magnetic ore and remove the iron impurities from the non-metallic ore, such as mica powder, quartz sand, potassium, feldspar, nepline, fluorite, sillimanite, spodumene,kaoline, manganese ore, weak magnetite,pyrrhotite, calcined ore, ilmenite,hematite, limonite, siderite, chromite, wolframite, columbite-tantalite, red mud. It also can be used in iron-removal operation of coal, non-magnetic ore and building materials etc.

Main Features

2. 8000gs-14000gs (ring with surface) two kinds of magnetic field strength can be designed according to the user's site demand, 11000gs is generally used for the middle section of the high purity products de-ironing process, the latter section needs to be equipped with electromagnetic vertical ring magnetic separator or electromagnetic slurry machine for further de-ironing, 12000gs-14000gs can be used for the terminal de-ironing of common materials.

3. The iron discarding ring belt adopts PU polyurethane type, the service life is 1.5 times-2 times that of PVC ring belt, the side retaining edge of the ring belt uses large S type or straight edge type instead of traditional small S type, which can effectively prevent the entrainment of materials and avoid unnecessary waste.

4. Drive roller and ring belt are equipped with guide grooves inside, which can effectively prevent the ring belt from deflection, rippling and even tearing, and the flat surface is smoother, which can extend the service life of the ring belt while removing iron.

5. Drive part of the first-line brands such as Wannan motor, the national joint warranty, mechanical failure rate is lower.

6. All stainless steel shell, extend the service life, effectively prevent secondary pollution of materials.

|

Model

|

Panel Width (mm)

|

Magnetic Panel Length

(mm)

|

Magnetic Intensity

(Gs )

|

Feed-in Density

(%)

|

Water Pressure

(Mpa)

|

Mineral Particle (mm)

|

Capacity

(t/h)

|

Power (KW)

|

|

SGB-0815

|

800

|

1500

|

15000

|

20 ~25 %

|

≥ 0 . 2

|

-3

|

8-10

|

1. 1

|

|

SGB-1020

|

1000

|

2000

|

15000

|

|

|

-3

|

10-15

|

1. 5

|

|

SGB-1220

|

1200

|

2000

|

15000

|

|

|

-3

|

15-20

|

2. 2

|

|

SGB-1525

|

1500

|

2500

|

15000

|

|

|

-3

|

20-35

|

2. 2

|

|

SGB-2025

|

2000

|

2500

|

15000

|

|

|

-3

|

25-30

|

3

|

|

SGB-2030

|

2000

|

3000

|

15000

|

|

|

-3

|

25-30

|

3

|

|

SGB-2525

|

2500

|

2500

|

15000

|

|

|

-3

|

35-40

|

4

|

|

SGB-2530

|

2500

|

3000

|

15000

|

|

|

-3

|

35-40

|

4

|

Q: 1.What is your machine used for ?

1). Our Flat Magnetic Separator is Used for remove the iron impurities in wet process and purify the non-metallic minerals, such as quartz, sodium or potassium feldspar.In addition, with high magnetic intensity, it has a very good effect in separating the weakly magnetic minerals, like hematite, specularite, limonite, siderite, manganese ore, etc.

Q: 2.Are you factory or trade company?

A: Yes dear,we are the Professional manufacturer from 1985.So we could give you original factory price than those trade companies.

We're also warmly welcome your Visiting our factory if you are coming to China.Please Call at +86-18870736160

Q: 3.Can I operate it well, if I have no experience?

A: Do not worry! Our machines is designed to use easily.You are welcome to visit our company to be trained here,And we could arrange the engineer to go to your country/company to train your workers directly as your requested and the relative travel cost will be on your account.

Q: 4.Can you send me the video to show how the machine works?

A: Surely.we have made video of every machine,so if you need we can send for you to checking in clearly.

Q: 5. What should I take care when using the machine?

A: Please using the machine in regular and Keeping the machine away from thinner and other chemical liquid.

Q: 6.How about your Service ?

A: All of our machines have one year warranty and Wholelife Technology support to make sure your machine work well.

Q: 7.How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: 8.What about the payment method?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q:9 What's Information we need from your side ?

A: What kind of ore do you want to process ? The Capacity per hour do you need ? and the Max feeding size of your material ?

1). Our Flat Magnetic Separator is Used for remove the iron impurities in wet process and purify the non-metallic minerals, such as quartz, sodium or potassium feldspar.In addition, with high magnetic intensity, it has a very good effect in separating the weakly magnetic minerals, like hematite, specularite, limonite, siderite, manganese ore, etc.

Q: 2.Are you factory or trade company?

A: Yes dear,we are the Professional manufacturer from 1985.So we could give you original factory price than those trade companies.

We're also warmly welcome your Visiting our factory if you are coming to China.Please Call at +86-18870736160

Q: 3.Can I operate it well, if I have no experience?

A: Do not worry! Our machines is designed to use easily.You are welcome to visit our company to be trained here,And we could arrange the engineer to go to your country/company to train your workers directly as your requested and the relative travel cost will be on your account.

Q: 4.Can you send me the video to show how the machine works?

A: Surely.we have made video of every machine,so if you need we can send for you to checking in clearly.

Q: 5. What should I take care when using the machine?

A: Please using the machine in regular and Keeping the machine away from thinner and other chemical liquid.

Q: 6.How about your Service ?

A: All of our machines have one year warranty and Wholelife Technology support to make sure your machine work well.

Q: 7.How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: 8.What about the payment method?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q:9 What's Information we need from your side ?

A: What kind of ore do you want to process ? The Capacity per hour do you need ? and the Max feeding size of your material ?

Warmly Welcome to Sending Inquiry,We will give 100% positive responses.

Hot Searches