1.PANASONIC servo motor

2.Carbon steel frame, all the parts which can contact products are 304 stainless steel.

3. Packing speed: 30 bags/min

4. Europe hole for hanging

5. Punch hole to remove the air

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

zhongminTaifeng machine

-

Power:

-

11kw

-

Dimension(L*W*H):

-

18*3*3

-

Weight:

-

50

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Electric control system:

-

inverter control

-

Temperature control system:

-

digital display temperature control automatic constant temperature

-

Suitable raw material:

-

latex,PVC,nitrile

-

mold:

-

aluminum hand mold

-

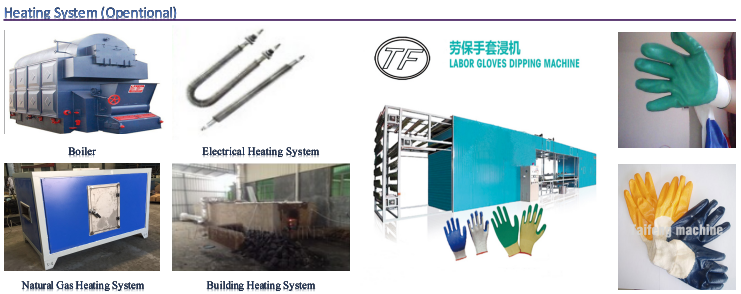

Heating system:

-

automatic thermal cycle system

-

Gumming way:

-

360 rotation cementing

-

Certification:

-

CE

Quick Details

-

Production Capacity:

-

500 pairs/hr

-

Voltage:

-

380V

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

zhongminTaifeng machine

-

Power:

-

11kw

-

Dimension(L*W*H):

-

18*3*3

-

Weight:

-

50

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Electric control system:

-

inverter control

-

Temperature control system:

-

digital display temperature control automatic constant temperature

-

Suitable raw material:

-

latex,PVC,nitrile

-

mold:

-

aluminum hand mold

-

Heating system:

-

automatic thermal cycle system

-

Gumming way:

-

360 rotation cementing

-

Certification:

-

CE

Product Description

1) Machine according to various materials (natural rubber, butyronitrile, PVC) PU curing process of humanized design, reasonable process, automatic balance fill glue system, make products to be stable, uniform coating thickness, length, No hanging point, temperature uniformity, high output, easy to demould, etc.

2) Oven using hot air circulation principle, the internal temperature of the oven, with high performance of insulation materials, ensure the temperature loss effectively, thus improve the thermal efficiency of the machine, the machine automatic temperature control system is adopted for the heating system, with high performance control switch, improve the accuracy of temperature control, so as to improve the product percent of pass.

3) Special design of the elasticity of the piston mold connection device, mold replacement is simple, no off mold phenomenon. Labor insurance gloves production line adopts continuous production method and direct leaching method, uniform film-forming, color and lustre is gorgeous, a variety of specifications can be online at the same time, production line length have 30 meters, 24 meters, 18 meters and so on.a High automation degree, large output, configurable demoulding automatically, Can be installed according to customer's production site design production line length.

2) Oven using hot air circulation principle, the internal temperature of the oven, with high performance of insulation materials, ensure the temperature loss effectively, thus improve the thermal efficiency of the machine, the machine automatic temperature control system is adopted for the heating system, with high performance control switch, improve the accuracy of temperature control, so as to improve the product percent of pass.

3) Special design of the elasticity of the piston mold connection device, mold replacement is simple, no off mold phenomenon. Labor insurance gloves production line adopts continuous production method and direct leaching method, uniform film-forming, color and lustre is gorgeous, a variety of specifications can be online at the same time, production line length have 30 meters, 24 meters, 18 meters and so on.a High automation degree, large output, configurable demoulding automatically, Can be installed according to customer's production site design production line length.

Specification

|

Model

|

TF-BJX-18m

|

TF-BJX-25m

|

TF-BJX-30m

|

|

Capacity(Pairs/Hr)

|

500 pairs/hr

|

1000 pairs/hr

|

1250 pairs/hr

|

|

Power(kw/时)

|

11 kw/hr

|

15 kw/hr

|

30 kw/hr

|

|

Mold(Pcs)

|

920 Pcs

|

1700 Pcs

|

2960 Pcs

|

|

Heat Sumption(Kcal/Hr)

|

22.0000 Kcal/Hr

|

30.0000 Kcal/Hr

|

50.0000 Kcal/Hr

|

|

Weight(Ton)

|

50 T

|

60 T

|

70T

|

Details Images

Final Product

Related products

Hot Searches