High resolution optical CCD Alignment system for precisely mounting BGA and Components. Mounting accuracy is within 0.01mm

﹡ Widely used in Chip Level Repairing in laptop, PS3, PS4, XBOX360, Moblie Phone, Computer, TV, control boards etc.

﹡ Rework BGA, CCGA, QFN, CSP, LGA, SMD, LED etc.

﹡ Automatic desoldering, Mounting and Soldering, automatic pick up chip when desoldering completed.

﹡ HD CCD Optical Alignment system for precisely mounting BGA and Components.

﹡ BGA mounting accuracy within 0.01mm , Repair success rate 99.9%.

﹡ Laser Positioning for Fast Positioning BGA Chip and motherboard.

﹡ Superior Safety Functions, with Emergency protection.

﹡ User-friendly operation, Multi-functional ergonomic system.

|

Specifications

|

|

|

|

|||

|

1

|

Total power

|

5400w

|

|

|||

|

2

|

3 independent heaters

|

Top hot air 1200w, lower hot air 1200w, bottom infrared preheating 2700w

|

|

|||

|

3

|

Voltage

|

AC220V±10% 50/60Hz

|

|

|||

|

4

|

Electric parts

|

7'' touch screen + high precision intelligent temp control module + stepper motor driver + PLC + LCD display + high resolution optical CCD system + laser positioning

|

|

|||

|

5

|

Temperature control

|

K-Sensor closed-loop + PID automatic temp compensation + temp module, temp accuracy within ±2℃.

|

|

|||

|

6

|

PCB positioning

|

V-groove + universal fixture + movable PCB shelf

|

|

|||

|

7

|

Applicable PCB size

|

Max 400x420mm Min 22x22mm

|

|

|||

|

8

|

Applicable BGA size

|

1x1mm~80x80mm

|

|

|||

|

9

|

Dimensions

|

740x630x710mm (L*W*H)

|

|

|||

|

10

|

Net weight

|

70 Kg

|

|

|||

◆

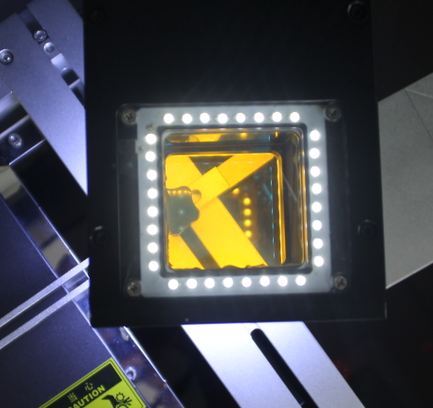

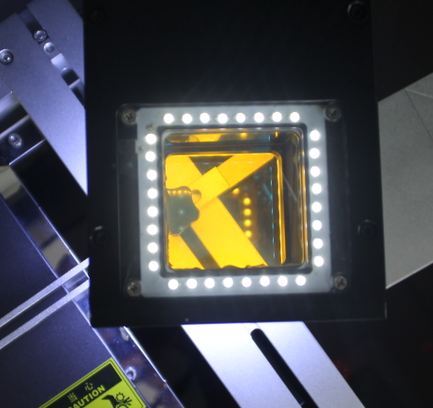

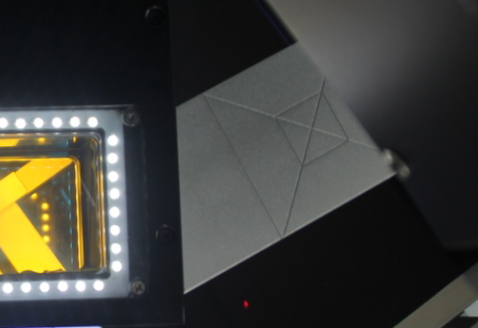

Precise optical alignment system

① Color optical system with functions of split vision, two color separation, zoom in/out and micro-adjust, equipped with aberration detection device, with auto focus and software operation

② CCD camera amplify up to 200x, with top/down light brightness adjust function, mounting accuracy is within 0.01 mm

◆

Advanced features

① Top hot air flow is adjustable, to meet the demand of any chips.

② Desoldering, mounting and soldering automatically. Auto feeding system enabled.

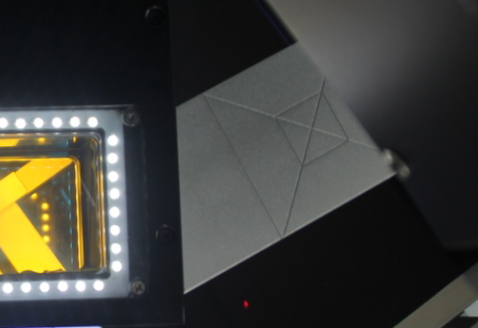

③ Built-in infrared laser positioning, help fast positioning for PCB.

④ Top heating head and mounting head 2 in 1 design.

⑤ Mounting head with built-in pressure testing device, to protect the PCB from being crushed.

⑥ build-in vacuum in mounting head pick up BGA chip automatically after desoldering completed.

◆

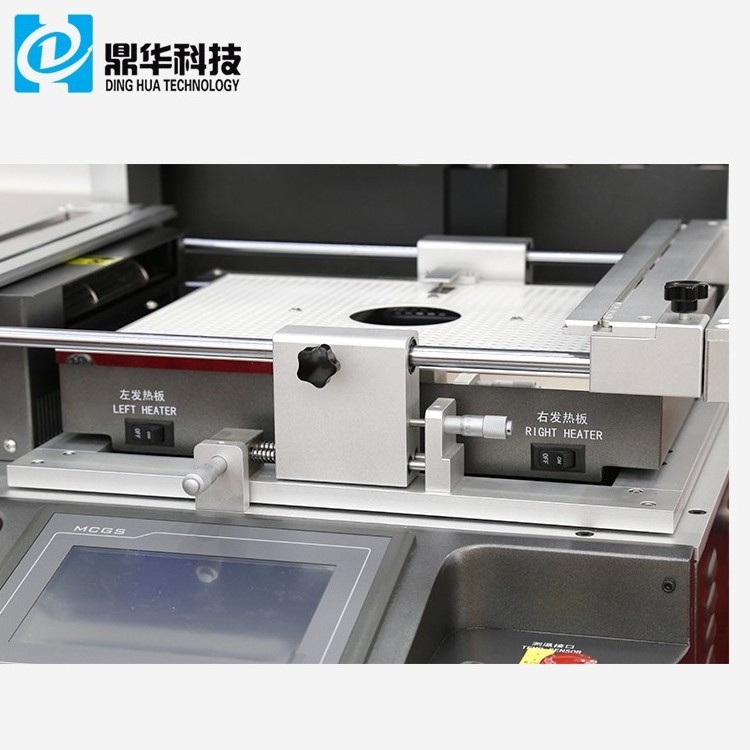

Three independently controlled heaters

① top and bottom heaters are hot-air heating, the third is infrared preheating zone, the top and bottom heaters can set 8 segments rising temperature/constant time/temperature rising slope , can save tens of thousands of groups temperature curves.

② it can heat PCB board and bga chips at the same time. And the third IR heater can preheat the PCB board from bottom evenly, to avoid PCB from deformation during repair process. All three heaters can heat independently .

③ It uses k-type thermocouple closed-loop control and PID automatic temperature compensation system, together with PLC and temperature module to enable precise temperature deviation to ±2 degree centigrade.

④ The external sensor can detect temperature precisely, analyze and calibrate the real temperature curve accurately at any time.

◆

Multi-functional ergonomic system

① bottom heater can be adjusted up and down.

② Adopted all kinds of magnetic top and bottom nozzles, with 360° rotation, easy for installation and replacement, customized sizes are available.

③ Multi-functional PCB support shelf, can be moved along X axis, together with universal fixture and V-groove bracket, suitable for all kind of PCB positioning.

④ powerful cross-flow fan automatically cool the PCB board fast after desoldering or soldering completed, it can prevent the heaters from aging. Fan will be shut down automatically when the heaters temperature drops to normal temperature.

◆

Superior safety functions

Machines are CE certification guaranteed. It is equipped with emergency button. Also there is voice warning around 5 seconds before soldering/desoldering process complete. With automatic power-off protection device when abnormal accident happens, with a double over-heating protection control.

High resolution optical CCD Alignment system for precisely mounting BGA and Components. Mounting accuracy is within 0.01mm

Built-in infrared laser positioning, help fast positioning for PCB board.

Auto feeding system enabled.

Desoldering: mounting head auto pick up bga chip and place it on the feeding plate.

Soldering: mounting head auto pick up bga chip from feeding plate.

|

Packaging

|

|

|

|

Size

|

77cm (L) * 72cm(W) * 73cm(D)

|

|

|

G.W.

|

110 Kg

|

|

|

Packaging Details

|

Strong wooden case +wooden bars+ proof foams and wrapped film

|

|

|

Delivery

|

|

|

|

◆ Sample woulde be sent within 5 business days after receiving full payment. 7-15 days for bulk order. ◆ Shipping By DHL, FedEx, TNT, EMS, UPS express ,or by air or sea, either is at your need.

|

|

|