- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized according to your requirements

-

Weight:

-

2600 KG

-

Place of Origin:

-

Henan,China

-

Voltage:

-

220V-480V (TBD)

-

Power:

-

4.5-60kw

-

Key Machines:

-

PLC, fan, Heat pump

-

Product name:

-

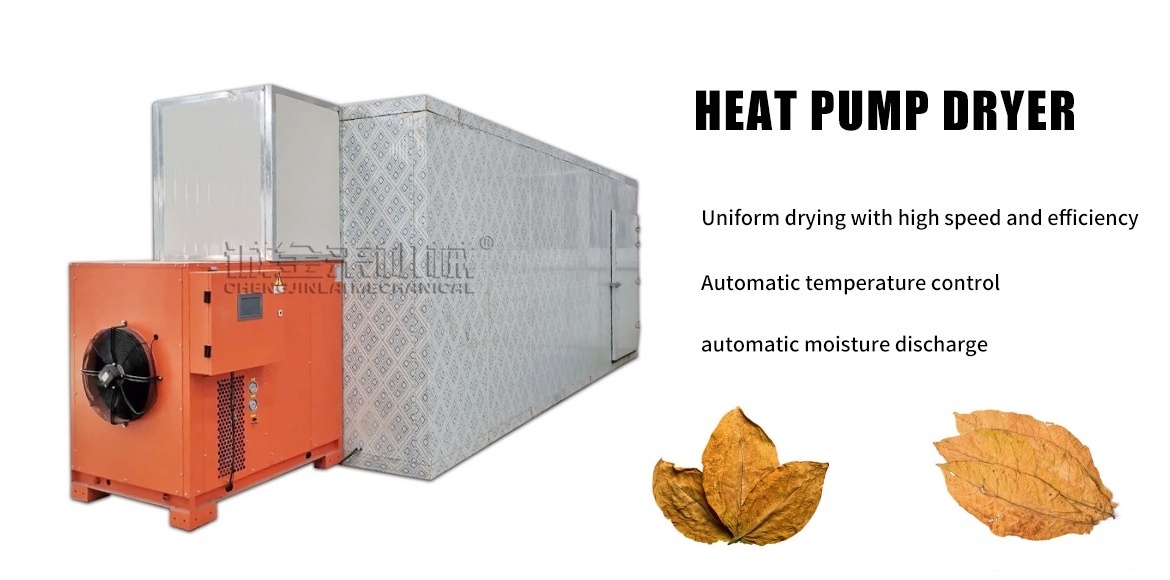

heat pump dryer

-

Type:

-

CJL-H20

-

Production Capacity:

-

Customized according to your requirements

-

Applicable raw materials:

-

Drying and processing of fruits, vegetables, seafood, etc.

-

Colour:

-

According to customer's demand

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

temperature:

-

Adjustable

-

Control System:

-

plc+touch screen

-

Materials:

-

stainless steel

-

Features:

-

Drying/Dehumidifying

Quick Details

-

Machinery Capacity:

-

Evaporation Capacity(30kg/h)

-

Brand Name:

-

CHENG JINLAI MECHANICAL

-

Year:

-

2024

-

Dimension(L*W*H):

-

Customized according to your requirements

-

Weight:

-

2600 KG

-

Place of Origin:

-

Henan,China

-

Voltage:

-

220V-480V (TBD)

-

Power:

-

4.5-60kw

-

Key Machines:

-

PLC, fan, Heat pump

-

Product name:

-

heat pump dryer

-

Type:

-

CJL-H20

-

Production Capacity:

-

Customized according to your requirements

-

Applicable raw materials:

-

Drying and processing of fruits, vegetables, seafood, etc.

-

Colour:

-

According to customer's demand

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

temperature:

-

Adjustable

-

Control System:

-

plc+touch screen

-

Materials:

-

stainless steel

-

Features:

-

Drying/Dehumidifying

Product Description

Factory Direct Sales Multifunctional Adjustable Temperature Heat Pump Air Dryer Food Dehydrator Tobacco Barn Machine

|

Various energy operating costs

|

Heat consumption kcal

|

Actual calorific value

|

Amount of energy consumed

|

Energy cost

|

|

Electric heating

|

8600

|

817 kcal/degree

|

105 degrees

|

$0.11/kWh

|

|

Coal-fired boiler

|

|

1750 kcal/kg

|

49kg

|

$0.14 /kg

|

|

Oil boiler

|

|

8240 kcal/kg

|

0.4kg

|

$0.86 /kg

|

|

Kinchem heat pump dryer

|

|

2580 kcal/m

|

33 degrees

|

$0.11/kWh

|

Comparison table of energy consumption between heat pump dryer and traditional drying.

The material drying process is a huge energy-consuming process. According to statistics, in most developed countries, the energy consumed for drying accounts for 7%-15% of the country's total energy consumption, while the thermal efficiency is only 25%-50%. , and most drying processes, especially for heat-sensitive materials (such as food and biological materials), will have an impact on their color, nutrition, flavor and texture. The operating cost of a heat pump dryer is only 30% of that of an electric heating dryer, 40% of that of a fuel-fired dryer, and 60% of that of a coal-fired dryer, and the heat pump dryer does not consume any materials.

Raw materials & final products

Heat pump dryers can be widely used in food, agricultural (by-product) products, seafood, paper products, wood, leather, chemicals, tobacco, medicine, etc.

Seafood such as sea cucumber, fish, shrimp, abalone, kelp, etc.;

Vegetables such as tomatoes, peppers, mushrooms, day lilies, edible fungi, etc.

Specification

|

Model

|

Unit

|

CJL-3P

|

CJL-7P

|

CJL-12P

|

CJL-20P

|

|||

|

Voltage frequency

|

V-HZ

|

220v-50HZ

|

380v/3N/50HZ

|

380v/3N/50HZ

|

380v/3N/50HZ

|

|||

|

Refrigeration capacity

|

kw

|

7.5

|

17.5

|

30

|

50

|

|||

|

Heating capacity

|

kw

|

10.5

|

26

|

45.2

|

74.4

|

|||

|

Rated power

|

kw

|

3.3

|

7.35

|

12.51

|

21.5

|

|||

|

Rated current

|

A

|

15

|

14.7

|

25.02

|

43

|

|||

|

Moisture removal capacity

|

L/H

|

12

|

30

|

50

|

84

|

|||

|

Maximum air outlet temperature

|

℃

|

75℃

|

75℃

|

75℃

|

75℃

|

|||

|

Refrigerant charge

|

g

|

2500g

|

4200g

|

4000g*2

|

7200g*2

|

|||

|

Noise

|

dB(a)

|

≤75

|

≤75

|

≤75

|

=75

|

|||

|

Air volume

|

m3/h

|

Internal fan customization

|

|

|

|

|||

|

Exhaust maximum pressure

|

Mpa

|

≤3.0Mpa

|

≤3.0Mpa

|

≤3.0Mpa

|

≤3.0Mpa

|

|||

|

Inspiratory maximum pressure

|

Mpa

|

≤0.75Mpa

|

≤0.75Mpa

|

≤0.75Mpa

|

≤0.75Mpa

|

|||

|

Protection against electric shock level

|

|

Level I

|

Level I

|

Level I

|

Level I

|

|||

|

Protection level

|

|

IPX4

|

IPX4

|

IPX4

|

IPX4

|

|||

|

Implementation standards

|

|

QKNDQ2-2019

|

QKNDQ2-2019

|

QKNDQ2-2019

|

QKNDQ2-2019

|

|||

|

Dimensions

|

mm

|

1620*1020*1280

|

1720*1220*1280

|

2120*1520*1590

|

2320*1820*2090

|

|||

|

Weight

|

kg

|

240kg

|

300kg

|

520kg

|

700kg

|

|||

The above parameters are based on specific working conditions, and the drying time changes due to different material structures.

Our factory supports customization

.

Other types of dryers:

Working principle

The heat pump is essentially a heat-raising device. The high-temperature heat pump drying unit uses the inverse Carnot principle to absorb heat from the surrounding environment and transfer it to the heated object (higher temperature object). Its working principle is similar to that of refrigeration. The machines are the same and work according to the reverse Carnot cycle. The only difference is that the operating temperature range is different.

Product Details

Energy-saving and high-efficiency external rotor axial flow fan

It has compact structure, easy installation, reliable operation, low noise, energy saving and high efficiency, and an average service life of more than 30,000 hours.

Large evaporator

The system design is optimized and improved. The heat exchange capacity is 1.2 times higher than that of its peers. It is economical, durable and corrosion-resistant. It has excellent water-skiing performance and can reduce wind resistance. The use of high-quality water-resistant aluminum foil to make inner copper tubes and corrugated aluminum foil structures greatly improves efficiency.

International brand powerful compressor

Using the American Copeland compressor, the performance is stronger and the adaptability is stronger. On the basis of effectively ensuring the service life of the equipment, it is equipped with multiple safety features such as overcurrent protection and phase loss protection.

Well-known brand temperature probe

Using Japan's Oizumi thickened and thickened temperature probe, it can accurately sense temperature changes and keep the temperature constant.

Packing & Delivery

Our factory packaging method:

1. All machines should be wrapped with plastic film first. The machine is packed in wooden boxes or transported in unpackaged containers to prevent damage during transportation.

2. Make a wooden box according to the size and weight of the machine, put it into the machine after loading and fix the box.

3. Put machine parts into fixed containers to avoid collision, wear or loss.

4. Our factory has a strict quality management system and a quality inspection department. Only products that pass the inspection can leave the factory.

5. We can produce products of different sizes according to your phase requirements and give appropriate discounts based on your order quantity.

We will choose the most convenient and economical way to deliver your goods. If you have special requirements for delivery, you can

contact us

in advance and we provide customization.

Why choose us

Henan Chengjinlai Machinery Manufacturing Co., Ltd. is located in Dahuangye Industrial Park, Gongyi City, Henan Province. It has a factory building of more than 10,000 square meters. It is a machinery and equipment manufacturer focusing on R&D, production and sales. It mainly produces briquette machines, charcoal machines, carbonization furnaces, hookah charcoal forming machines, briquette machines and other mechanical equipment. So far, the company's products have passed more than 20 national patents, and have passed multiple quality system certifications such as ISO, TUV, and CE. In addition, the company adheres to the business philosophy of quality and service and wholeheartedly provides high-quality products and services to new and old customers to meet the needs of our customers to the greatest extent.

Serve

Pre-sale service

1. Sample testing support.

2. Inquiry and consultation support.

3. Quality issues raised by users will be dealt with 24 hours a day.

4. Our factory professionals will plan the production line for you free of charge.

3. Quality issues raised by users will be dealt with 24 hours a day.

4. Our factory professionals will plan the production line for you free of charge.

After-sales service

1. Teach you how to install the machine.

2. Teach you how to use the machine.

3. Engineers can install machines overseas.

4. If it is necessary to send someone to deal with the problem on site, they will arrive at the site in time for service.

2. Teach you how to use the machine.

3. Engineers can install machines overseas.

4. If it is necessary to send someone to deal with the problem on site, they will arrive at the site in time for service.

FAQ

Q: Are all the machines you produce of uniform standards?

A: We will customize the machine for you according to your requirements.

Q: How to choose the right machine?

A: Please tell us your production raw materials and the output you need and other requirements, we will recommend the most suitable product for you.

Q: How is the machine installed?

A: Generally, we provide complete machine delivery. We can also arrange technicians to go to the site to guide the installation.

Q: What is the supply situation of main parts?

A: Spare parts are always provided at cost price, and a spare parts list will be provided when you purchase the machine.

Q: Do you test the machines before shipping?

A: Yes, we will test each machine and production line before shipment and send you the working video. You can also inspect the machine you purchased at our factory before delivery.

Q: Can I visit your factory?

A: We really warmly welcome every customer to visit our factory. Every year, many domestic and foreign customers come to visit our factory. Our company is located in Dahuangye Industrial Park, Gongyi City, Henan Province, China. You can get here by plane or train. The nearest airport is Zhengzhou Xinzheng International Airport, and the airport code is CGO. We will pick you up at the airport.

Hot Searches