- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

less than 1%

-

Voltage:

-

110V/220/,50HZ/60HZ

-

Place of Origin:

-

ZHE

-

Dimension(L*W*H):

-

1230*380*420mm

-

Weight:

-

95 KG

-

Core Components:

-

Other

-

Function:

-

Washing Filling Capping

-

Product name:

-

Liquid Filling Machine

-

After-sales Service Provided:

-

Online Support

-

Keywords:

-

Fillng Machine

Quick Details

-

Machinery Capacity:

-

500BPH, 2000BPH, 1000BPH, 200BPH

-

Packaging Material:

-

Paper, Wood

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

less than 1%

-

Voltage:

-

110V/220/,50HZ/60HZ

-

Place of Origin:

-

ZHE

-

Dimension(L*W*H):

-

1230*380*420mm

-

Weight:

-

95 KG

-

Core Components:

-

Other

-

Function:

-

Washing Filling Capping

-

Product name:

-

Liquid Filling Machine

-

After-sales Service Provided:

-

Online Support

-

Keywords:

-

Fillng Machine

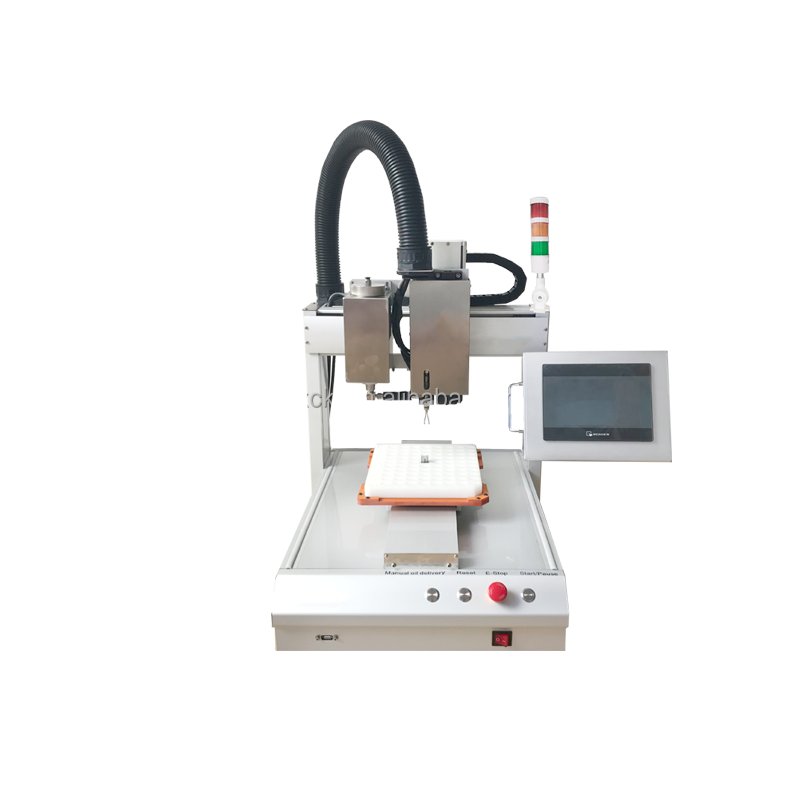

Specification

|

heating oiling machine technical parameters

|

|

|

|

|

||||

|

Single head oil injection machine technical parameters:

|

|

|

|

|

||||

|

parameter

|

|

unit

|

Parameter value

|

|

||||

|

Equipment size

|

|

mm

|

500*600*850mm

|

|

||||

|

Maximum speed

|

X-axis X-axis

|

Mm/s Mm/sec

|

500mm/s

|

|

||||

|

|

Y-axis Y-axis

|

|

500mm/s

|

|

||||

|

|

Z-axis Z-axis

|

|

500mm/s

|

|

||||

|

Motion accuracy

|

|

mm

|

(+/-0.02)mm

|

|

||||

|

Filling accuracy

|

|

g

|

±0.02g

|

|

||||

|

Filling range

|

|

ML

|

0.3-2.0ml

|

|

||||

|

Driving mode

|

|

|

Motor + synchronous belt

|

|

||||

|

Control panel

|

|

|

Operation button to start emergency stop reset manual oil discharge

|

|

||||

|

Control interface

|

|

|

Position adjustment, microprogression, program selection

|

|

||||

|

Mode of movement

|

|

|

point-to-point

|

|

||||

|

controller

|

|

|

assorting

|

|

||||

|

Power source

|

|

v

|

110v-220v

|

|

||||

|

Maximum bearing capacity

|

|

kg

|

Table: 50 kg, Z axis: 3 kg

|

|

||||

Products Description

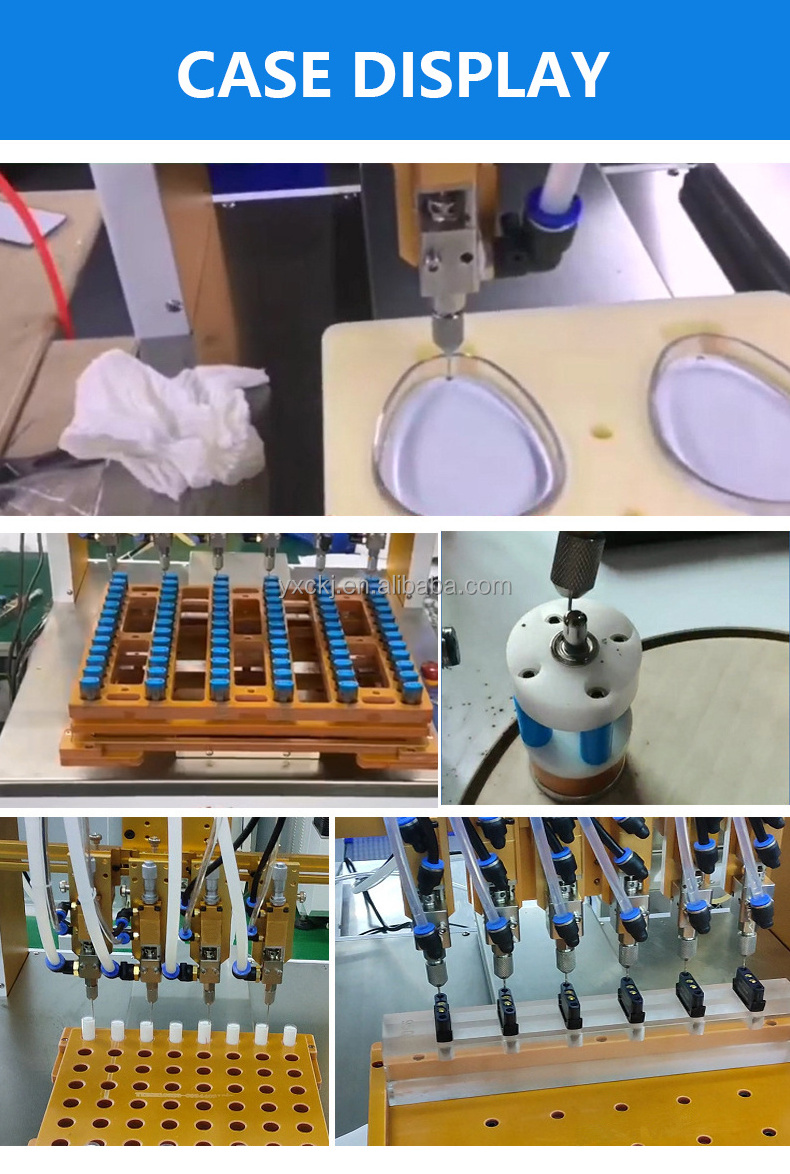

Feature

Desktop type, can be placed on the production line.

DIY mode, free matches of axis and heads, head number range is 1~12.

Optional Full English marked machine body, to be international application.

Multi-axis design with high rigidity aluminum alloy.

Double Yaxis type, automatic working alternatively, saving the time of placing object.

The glue automatic feeding, safe and silence.

Main components of the machine are high quality, ensure the reliability and accuracy.

Fixture and tooling available. Contact us for customization.

Packag

FAQ

Title goes here.

Q1: What is your Warranty for the product? How do you carry out it?

A1: We provide 1 Year Warranty for unit machine and 3 years warranty for main board.More details pls contact me.

Q2: May I buy samples from you?

A2: Yes! You are welcome to place sample order to test our superior quality and service.

Sample's price is the same as bulk's price.

Q3: What’s the leading time? (How long do you need to prepare my goods?)

A3: 1-3 working days for sample orders

3-20 working days for bulk order (based on different quantities).

Q4: How is your product quality?

A4: We provide supreme - Very rigorous testing process for Incoming Quality Control, Input Process Quality Control, and Final Quality Control for every piece. We follow 20 QC test procedure, and do 100% FQC to ensure your satisfaction.

Q5: Do you have any After-Sales service?

A5:Yes! We have professional After-sales Dept. follow-up.

If you have any technical problem or question with the goods, welcome to contact our Technical Support Dept. or our sales directly.

Q6: Are you just trading company or factory?

A6: We are professional manufacturer for automation machine since 2015.

Our factory is located in Baoan District, Shenzhen City, Guangdong Province. Welcome you to visit our factory.

Hot Searches