Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Qingdao city,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

22*2.8*2.8M

-

Power (kW):

-

75

-

Weight:

-

18000 KG

-

Name:

-

Pvc Pipe Production Line

-

Raw material:

-

PVC Granules

-

Keywords:

-

PVC Pipe Extruder Line

-

Final product:

-

PVC pipe

-

Usage:

-

Plastic Pipe Extrusion

-

Processing Type:

-

PVC Extrusion Machine

-

Product Type:

-

PVC Pipe Extruder Machine

-

Machine type:

-

Extrusion Plastic Making Production Machinery PVC Pipe Line

-

Pipe diameter:

-

20mm-800mm

-

Motor:

-

SIEMENS Brand

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

75 rpm

-

Place of Origin:

-

Qingdao city,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

22*2.8*2.8M

-

Power (kW):

-

75

-

Weight:

-

18000 KG

-

Name:

-

Pvc Pipe Production Line

-

Raw material:

-

PVC Granules

-

Keywords:

-

PVC Pipe Extruder Line

-

Final product:

-

PVC pipe

-

Usage:

-

Plastic Pipe Extrusion

-

Processing Type:

-

PVC Extrusion Machine

-

Product Type:

-

PVC Pipe Extruder Machine

-

Machine type:

-

Extrusion Plastic Making Production Machinery PVC Pipe Line

-

Pipe diameter:

-

20mm-800mm

-

Motor:

-

SIEMENS Brand

Product Description

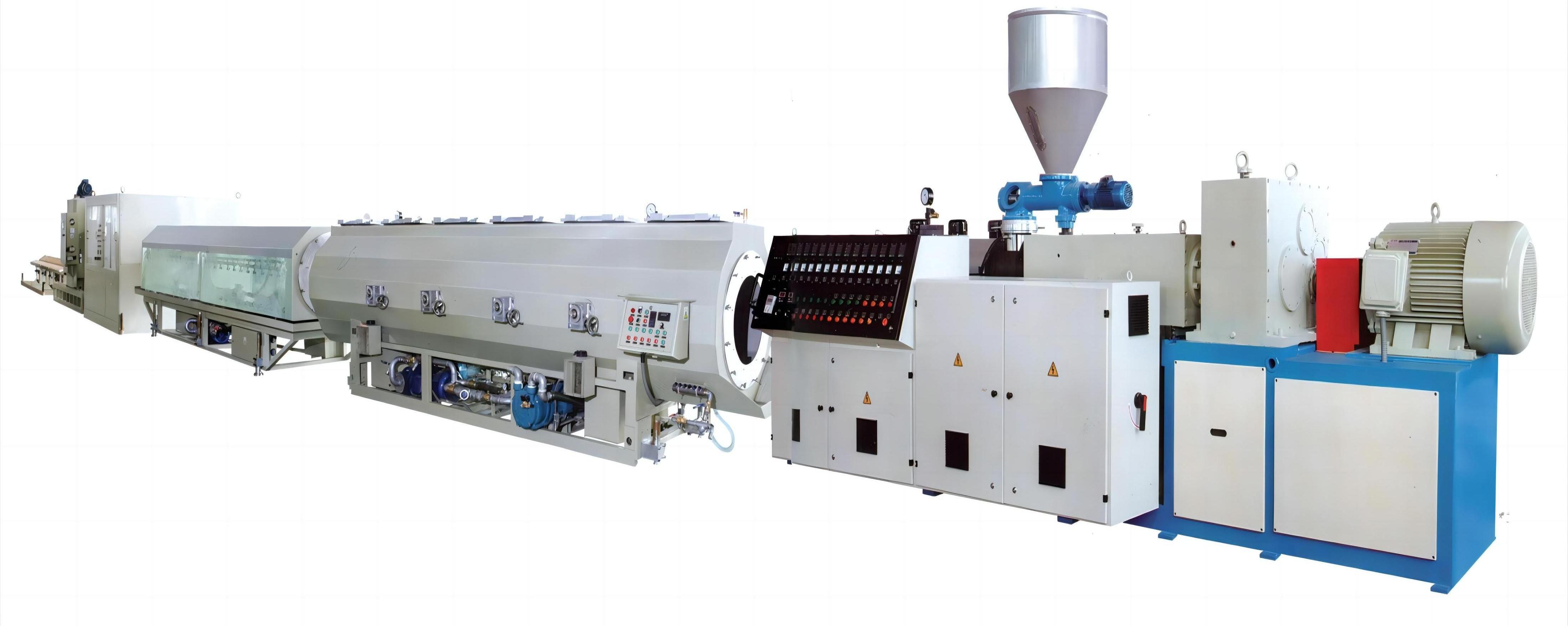

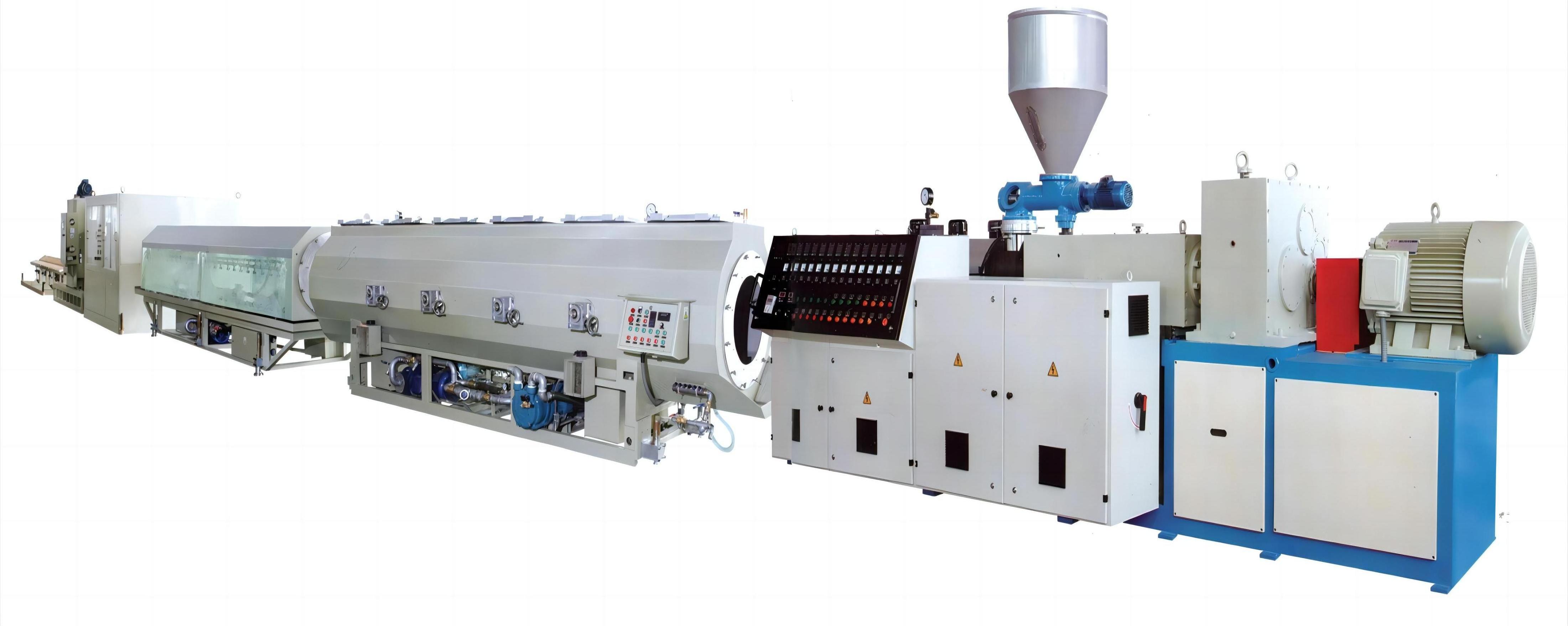

PVC pipe extrusion machine line

Plastic pvc pipe making machine with high speed

Plastic Pipe Making Machine PVC/UPVC/CPVC/PVC Pipe Extruding Machine for Sale

PVC pipe production line is mainly used for electric conduit pipe,agricultural water supply and drainage, construction watersupply and drainage. Because of its characteristics. CPVC pipe is widely used in oil field crude oil gathering and transportation,chemical corrosion resistant pipeline, hot water supply pipe line.

This line with reliable performance and high production eficiency. Our company can also manufacture special pipe production lines,e.g. spiral silencing pipe and core foaming pipe according to your requirements.

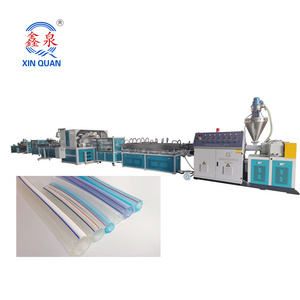

Under high-output requirement for small diameter pipe production, the double-extrusion technology shows great advantage. The characteristics of our dual-strand downstream equipment is with two sets of independent control circuit, the speed of each side can be adjusted respectively, and can even produce different diameter of the pipe at the same time. Four strand extrusion line is suitable for the ≦32mm pipe with high-speed production, unilateral pipe speed up to 25 m/min. This extrusion line adopts special screw and mould design, uniform plasticizing, fast production speed, low energy consumption. Easy controlling and operation,reduce the technical and running requirements the operators. And effectively save the workshop space.

PVC Double Extrusion, Four Stand Extrusion Line

Application

Which are commonly use in water drainage and cable/wire protection area. By adding on additional machine equipment, this line can also produce inner wall spiral pipe, inner wall hollow pipe as well as PP, PE, ABS, PPR, PEX and other types of plastic pipes.

Specification

|

Model

|

Pipe Diameter(mm)

|

Extruder Model

|

Output Capacity(Kg/H)

|

Total Power(Kw)

|

Max.speed(M/min)

|

|

YETPVC-50*2

|

16-50

|

SJ-51/105

|

40-150

|

55

|

6

|

|

YETPVC-110

|

50-110

|

SJ-51/105

|

80-150

|

60

|

6

|

|

YETPVC-160

|

63-160

|

SJ-65/132

|

150-300

|

100

|

5

|

|

YETPVC-250

|

110-250

|

SJ-80/156

|

280-400

|

130

|

3.5

|

|

YETPVC-450

|

250-150

|

SJ-92/188

|

350-700

|

150

|

1.5

|

|

YETPVC-630

|

315-630

|

SJ-92/188

|

450-750

|

190

|

0.9

|

|

YETPVC-800

|

400-800

|

SJ-110/220

|

1000-1300

|

320

|

0.6

|

Configuration and Related Technical Parameters

Features:

Our PVC pipe extrusion machine has features of low energy consumption, high output, stable running etc.

Clients also can choose double/four PVC pipe extrusion line to make small size PVC pipes.

Processing flow of plastic pvc pipe making machine extrusion line:

PVC powder + additive → mixing → spring feeding → twin screw extruder → mould and calibrator

→ vacuum forming machine → haul off machine → cutting machine → discharging rack

Our PVC pipe extrusion machine has features of low energy consumption, high output, stable running etc.

Clients also can choose double/four PVC pipe extrusion line to make small size PVC pipes.

Processing flow of plastic pvc pipe making machine extrusion line:

PVC powder + additive → mixing → spring feeding → twin screw extruder → mould and calibrator

→ vacuum forming machine → haul off machine → cutting machine → discharging rack

We have differen model of PVC pipe machine for making 16-800mm PVC pipe

|

No

|

Name

|

Qty

|

|

1

|

Spring Vacuum feeder

|

1set

|

|

2

|

Double Screw extruder

|

1set

|

|

3

|

Die head and mould

|

1set

|

|

4

|

Vacuum water cooling sizing tank

|

1set

|

|

5

|

water spraying cooling tank

|

1set

|

|

6

|

haul off machine

|

1set

|

|

7

|

saw dust cutting machine

|

1set

|

|

8

|

stacker

|

1set

|

Detailed images

Conical twin screw extruder machine with PLC control system

According to the requirements of different diameters, different wall thicknesses and different output of pipes, we have many models of special twin screw extruders and die head to choose from. It adopts a specially designed screw structure, which canevenly heat,plasticize PVC powder and extrude pipes .

High quality Die head

The mould is made of high-quality alloy steel, the internal flow channel is chrome-plated and highly polished, which is wear-resistant and corrosion-resistant; With the special sizing sleeve, the product production speed is hight and the surface of the pipe is good.

Complete set include extrusion die head, Slotting & water ring type calibration sleeve Apply to PVC single,dual,Four cavity

extrusion.

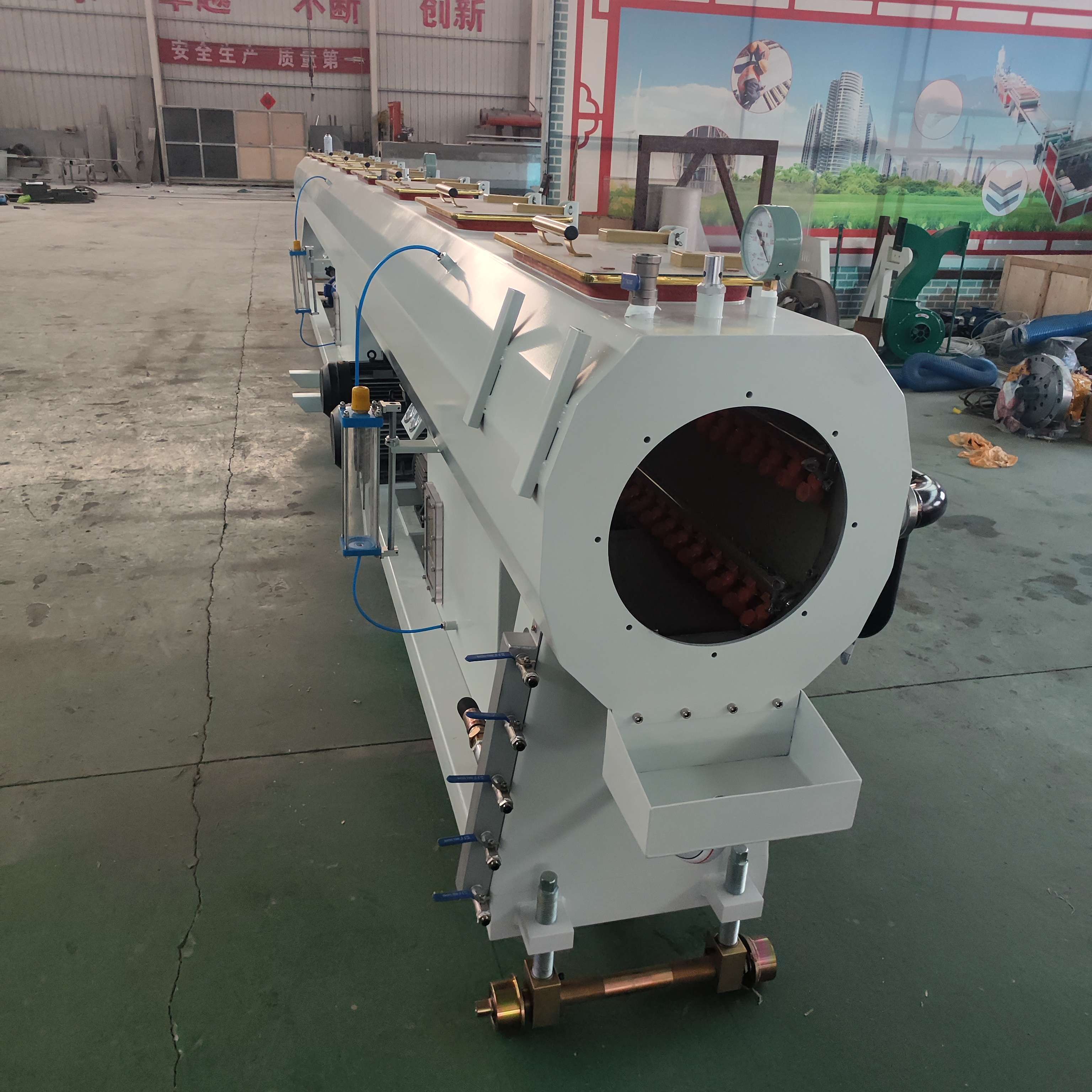

Vacuum calibration cooling tank

The calibrating and cooling tank can calibrate and cool the pvc pipe from mould,

so as to reach standard pipe size.

Include full set of vacuum and water pump.

Calibration Tank Length: 6m, Adopt 3mm thickness stainless steel board, Adopt 0.75KW Gearbox Speed Reducer Motor, Adjusting Distance equal to 800mm

Calibration Tank Length: 6m, Adopt 3mm thickness stainless steel board, Adopt 0.75KW Gearbox Speed Reducer Motor, Adjusting Distance equal to 800mm

Caterpillar Hall-off machine

Rubber block is soft material. Adopt best design,it can press products closed,and delivery stably.

Which is with imported frequency regulator,for different pipe diameter and extruder speed requirements, we designed all kinds of the Hall-off unit, have two caterpillars, three caterpillars, four caterpillars, six caterpillars until up to 16 caterpillars. The wide adjustable range for the Hall-off unit, running is stable and reliable, and small noise.

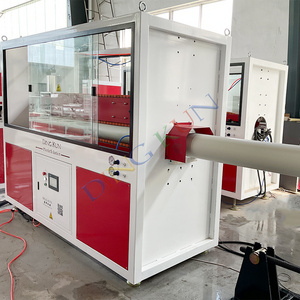

Cutting machine

Cutting Machine control by PLC,we can cutting by meter.We provide different saw to cut different material products,we also have two kind of cutter.One is saw cutter,another one is no-dust cutter(cutting by knife).

Most important,we also can confirm some special products cutting accuracy.

Most important,we also can confirm some special products cutting accuracy.

Stacker

Stacker length 4m. 1.5mm stainless steel board, Stacking by Gas cylinder, Adopt limited switch send out cutting signal.

Hot Searches