- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3.25KW+3.25KW

-

Weight:

-

24KG

-

Voltage:

-

220V

-

Year:

-

2022

-

Core Components:

-

Other

-

Model Number:

-

DF-12L-2

-

Product name:

-

Chicken Deep Fryer Machine

-

Application:

-

Fast Food Restaurant

-

Usage:

-

Making Frying Food

-

Material:

-

304 Stainless Steel

-

Capacity:

-

6/8/10/12/26/30L

-

Temperature Range:

-

60~200°C

-

MOQ:

-

2

-

Package:

-

Standard Wooden Package

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

TONLI

-

Dimension(L*W*H):

-

580x550x410mm

-

Power:

-

3.25KW+3.25KW

-

Weight:

-

24KG

-

Voltage:

-

220V

-

Year:

-

2022

-

Core Components:

-

Other

-

Model Number:

-

DF-12L-2

-

Product name:

-

Chicken Deep Fryer Machine

-

Application:

-

Fast Food Restaurant

-

Usage:

-

Making Frying Food

-

Material:

-

304 Stainless Steel

-

Capacity:

-

6/8/10/12/26/30L

-

Temperature Range:

-

60~200°C

-

MOQ:

-

2

-

Package:

-

Standard Wooden Package

Related Products

Product Specification

Power supply installation

: Check whether the power supply installation is normal, and it must be ensured that the power supply voltage is consistent with the furnace voltage.

Cylinder oil level line

: There is an oil level line engraved on the inner wall of the oil cylinder, and the oil level in the oil cylinder should be maintained during use. The maximum oil capacity is outside the "H" mark, and the minimum oil capacity is shown at the "MIN" mark, and the oil capacity can be used according to actual needs.

Working indicator

: plug in the plug, turn on the power, the green indicator is on, and the current has been supplied to the furnace. Rotate the thermostat clockwise, and align the required temperature scale value with the red dot. At this time, the yellow indicator light is on, and the green indicator light is off, indicating that the electric heating tube has worked and the oil in the cylinder has begun to heat up.

Automatic temperature control

: When the oil temperature rises to the set temperature, the thermostat can automatically cut off the power supply, at the same time the yellow indicator light is off, the green indicator light is on, and the electric heating tube stops working. When the oil temperature drops slightly, the thermostat can automatically turn on the power, the yellow indicator light is on, the green indicator light is off, the electric heating tube resumes work, and the oil temperature rises. This cycle is repeated to ensure that the oil temperature is constant within the set temperature range.

Cylinder head

: The cylinder head is set to keep the oil cylinder clean and warm. When adding the cover, it should be noted that there should be no water on the cover, so as to prevent water droplets from dripping into the cylinder and splashing the hot oil and hurting people.

Frying Basket

: Equipped with a dedicated frying basket for frying smaller foods. There are hooks and handles on the basket. When operating, immerse the basket in oil. After frying, lift the frying basket and hang it in the slot above the front of the oil tank to filter out the remaining oil. When frying large food, it can be directly put into the oil tank for frying.

Thermostat

: After work, please rotate the thermostat counterclockwise to the limit position, and cut off the power at the same time to ensure safety.

Cleaning

: When the old oil in the tank needs to be removed, it should be carried out after the oil temperature has dropped to normal temperature. First cut off the power supply, then take out the oil separator in the cylinder, and then pull out the electrical box from the slot at the rear of the bottom box. At this time, the electric heating tube and the electrical box are completely separated from the cylinder body and placed in a clean place, which can be easily Lift out the cylinder for a thorough cleaning.

Cleaning of the oil cylinder and electric heating pipe

: In order to make the stove safe and durable, the user should regularly remove the residue in the oil cylinder and the dirt on the electric heating pipe. In order to keep the oil cylinder and electric heating tube in a clean state for a long time.

Oil separator

: The oil separator in the oil tank is installed to protect the electric heating tube. When frying food, the oil separator must be placed in the oil tank.

Use of oil

: New vegetable oil (or meringue oil) should be used, old oil should not be used to avoid lowering the flash point and excessive boiling.

|

SIZE

|

DF-12L-2: 58X55X41CM

|

|

WEIGHT

|

24KG

|

|

VOLTAGE

|

220V

|

|

PACKAGE

|

WOODEN CASE

|

Manufacturing Technique

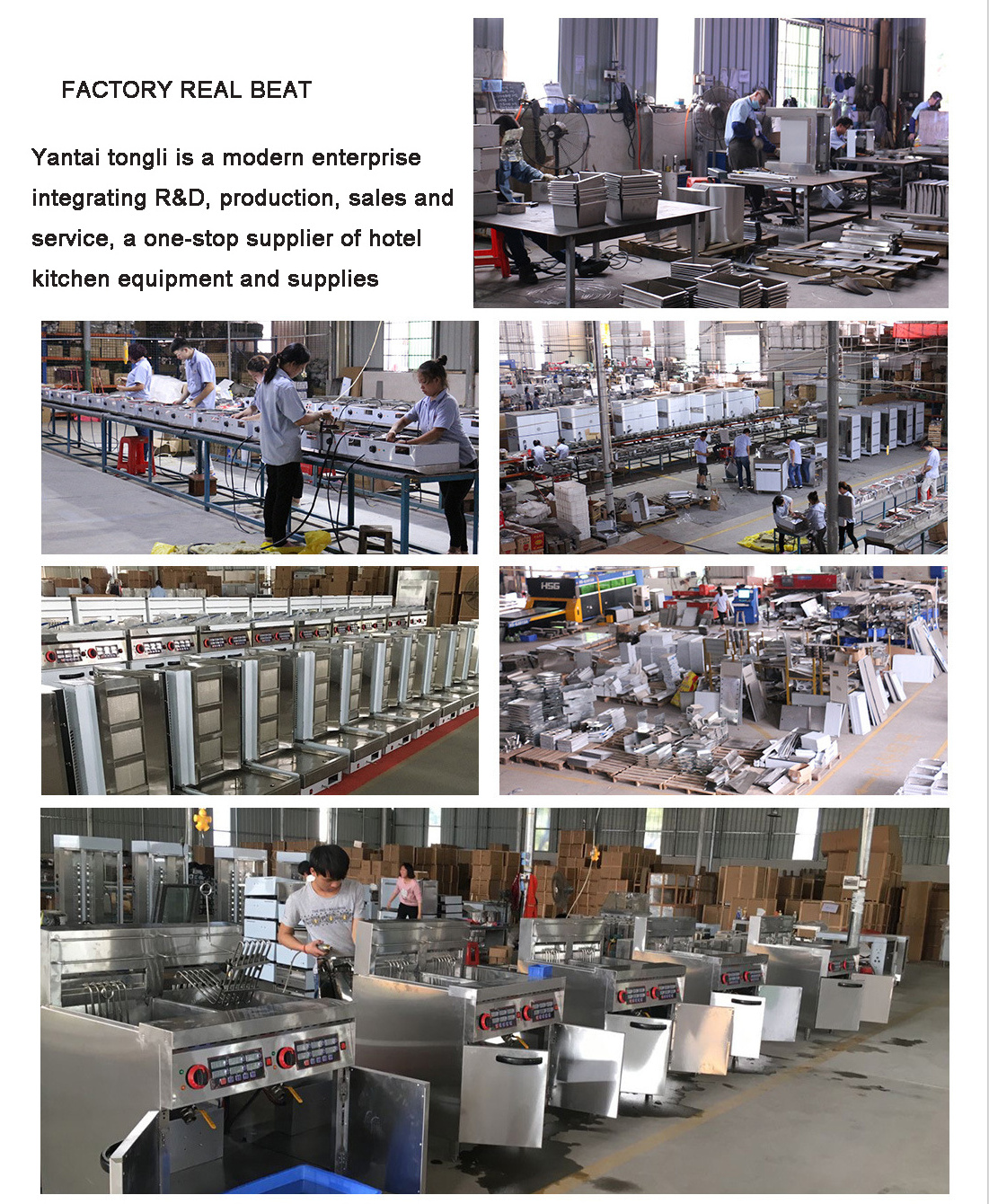

Company Introduction

About us

1、Founded in 1996; Focus on hotel supplies industry for 26 years;

2、Obtained ISO system certification; products passed national standards and international safety tests ,guaranteed international standard quality;

3、The workshop area is 8000 ㎡; the exhibition hall area is 5500 ㎡;

4、One-stop supporting services for commercial catering supplies; OEM/ODM services; sincerely recruiting distributors/brand agents;

5、With independent import and export rights; consistent service to global customers.

Customer Photos

Packing, shipping and payment

Packing .

Inner packing: transparent dustproof plastic bag, carton, foam, etc.

Outer packing: woven bag/carton/plywood, no need for fumigation.

All products are well packaged and delivered to your hands as standard ;

Or according to customer requirements.

Shipping .

1. Express courier like DHL, TNT, FedEx, UPS, EMS etc, shipping time is about 2-7 working days depends on country and area.

2. By air port to port : about 7-12 days depends on port.

3. By sea port to port : about 20-35 days

Or as per customer's request.

2. By air port to port : about 7-12 days depends on port.

3. By sea port to port : about 20-35 days

Or as per customer's request.

Payment .

T/T, L/C , Western Union and so on.

Normally T/T 40% deposit in advance , 60% before shipment. We will show you photos and videos of finished goods.

Normally T/T 40% deposit in advance , 60% before shipment. We will show you photos and videos of finished goods.

Hot Searches