Brief Introduction

A magnetic powder clutch is a special type of electromagnetic clutch which does not use friction plates. Instead, it uses a fine

powder of magnetically susceptible material (typically stainless steel) to mechanically link an otherwise free wheeling disc attached to one shaft, to a rotor attached to the other shaft. When a magnetic field is applied to the powder, it forms chains connecting the disc and rotor. The strength of the chains depends on the strength of the magnetic field. We use the finest

materials available for magnetic components to yield high friction indexes, as well as premium non-asbestos linings to improve

response time and extend working life.

- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

Inkjet Printer

-

Weight (KG):

-

20

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

zhele

-

Product name:

-

magnetic powder clutch for all kinds of machinery

-

Model:

-

Original Kyocera

-

Name:

-

magnetic powder clutch

-

Torque:

-

6N.m - 200N.m

-

Speed:

-

1000-1400 r/min

-

Gross Weight:

-

3.5kg - 56kg

-

Way of Cooling:

-

Natural cooling/ Water cooling

-

Color:

-

creamy white

-

Voltage:

-

24V DC

Quick Details

-

Condition:

-

New

-

Type:

-

Gripper

-

Use:

-

For Komori Printer

-

Printing Type:

-

Inkjet Printer

-

Weight (KG):

-

20

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

zhele

-

Product name:

-

magnetic powder clutch for all kinds of machinery

-

Model:

-

Original Kyocera

-

Name:

-

magnetic powder clutch

-

Torque:

-

6N.m - 200N.m

-

Speed:

-

1000-1400 r/min

-

Gross Weight:

-

3.5kg - 56kg

-

Way of Cooling:

-

Natural cooling/ Water cooling

-

Color:

-

creamy white

-

Voltage:

-

24V DC

Product Description

Magnetic Powder Clutch Best Price Hot Selling

1.Introduction of magnetic powder clutch:

Magnetic powder clutchcan transmit torque based on electromagnetic theory and the use of magnetic powder.It has the characteristics which magnetizing current and transmit torque has a linear relationship,It has advantages of fast response,simple structure,no pollution,no noise,no shock and vibration,energy-saving and so on.It is a versatile,superior performance of automatic control components.Magnetic clutch can also be used to buffer starting,overload protection,speed control and so on.

Magnetic powder clutchcan transmit torque based on electromagnetic theory and the use of magnetic powder.It has the characteristics which magnetizing current and transmit torque has a linear relationship,It has advantages of fast response,simple structure,no pollution,no noise,no shock and vibration,energy-saving and so on.It is a versatile,superior performance of automatic control components.Magnetic clutch can also be used to buffer starting,overload protection,speed control and so on.

2.Features of magnetic powder clutch

1)The transmission torque has a linear relationship with the magnetizing current. The size of the torque can get controlled within large range. Under normal circumstance, the magnetizing current has a linear relationship with transitive torque within range of 5%-100% rated torque.

2)The friction part will generate heat inevitably or even destroyed when it keep continuous sliding. But this device has a complete cooling set, it will not generate a lot of heat after long time running and it has a long service life.

3.Application of magnetic powder clutch

It is widely used in printing machinery, paper industry machinery, bag-making machinery, paper-making machinery , wire and cable machinery,coil machinery,wire winding machines,strapping bag machinery, textile machinery, weaving-dimensional machinery, woodworking machinery, steel extruders, CNC lathes, specialized machinery and so on.

4.Advantages of magnetic powder clutch

1) High-precision torque control

2) Superior durability,long life

3) The stability of a fixed superior torque characteristics

4) Continuous operation of the use of sliding

5) Ink sleek,non-shock

6) Suitable for high-frequency operation

1)The transmission torque has a linear relationship with the magnetizing current. The size of the torque can get controlled within large range. Under normal circumstance, the magnetizing current has a linear relationship with transitive torque within range of 5%-100% rated torque.

2)The friction part will generate heat inevitably or even destroyed when it keep continuous sliding. But this device has a complete cooling set, it will not generate a lot of heat after long time running and it has a long service life.

3.Application of magnetic powder clutch

It is widely used in printing machinery, paper industry machinery, bag-making machinery, paper-making machinery , wire and cable machinery,coil machinery,wire winding machines,strapping bag machinery, textile machinery, weaving-dimensional machinery, woodworking machinery, steel extruders, CNC lathes, specialized machinery and so on.

4.Advantages of magnetic powder clutch

1) High-precision torque control

2) Superior durability,long life

3) The stability of a fixed superior torque characteristics

4) Continuous operation of the use of sliding

5) Ink sleek,non-shock

6) Suitable for high-frequency operation

Advantages of Our magnetic powder Clutch

1) High-precision torque control

2) it is more resistant to wear, superior durability, longer life

3) The stability of a fixed superior torque characteristics, it doesn't exhibit stick-slip phenomenon or stiction

4) Simple structure, no pollution, no noise, no impact vibration energy saving

5) Suitable for high-frequency operation, it has a very fast response time

1) High-precision torque control

2) it is more resistant to wear, superior durability, longer life

3) The stability of a fixed superior torque characteristics, it doesn't exhibit stick-slip phenomenon or stiction

4) Simple structure, no pollution, no noise, no impact vibration energy saving

5) Suitable for high-frequency operation, it has a very fast response time

Detailed Images

Main Features

High Durability. The life of the magnetic powder clutch and magnetic brake rely on the life of the magnetic powder. Generally, the service life is 4500-7500 hours with non-overloaded

Good Cooling Design. The friction part will generate heat inevitably or even destroyed when it keep continuous sliding or overload. But it has the structure which inbreathe the compressed air to the interspaced, and release the heat to exterior. This type can also be used as natural cooling brake.

High Durability. The life of the magnetic powder clutch and magnetic brake rely on the life of the magnetic powder. Generally, the service life is 4500-7500 hours with non-overloaded

Good Cooling Design. The friction part will generate heat inevitably or even destroyed when it keep continuous sliding or overload. But it has the structure which inbreathe the compressed air to the interspaced, and release the heat to exterior. This type can also be used as natural cooling brake.

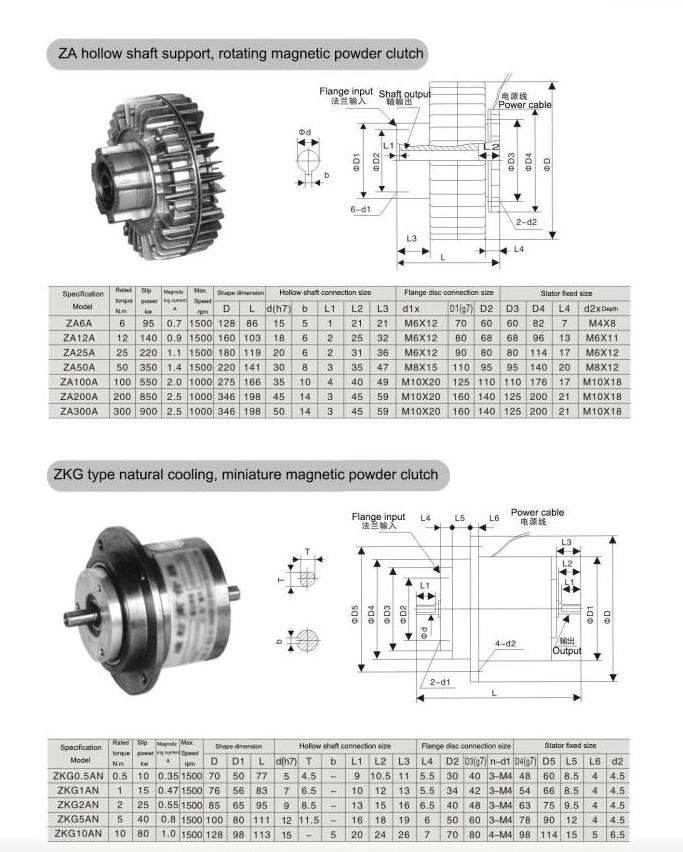

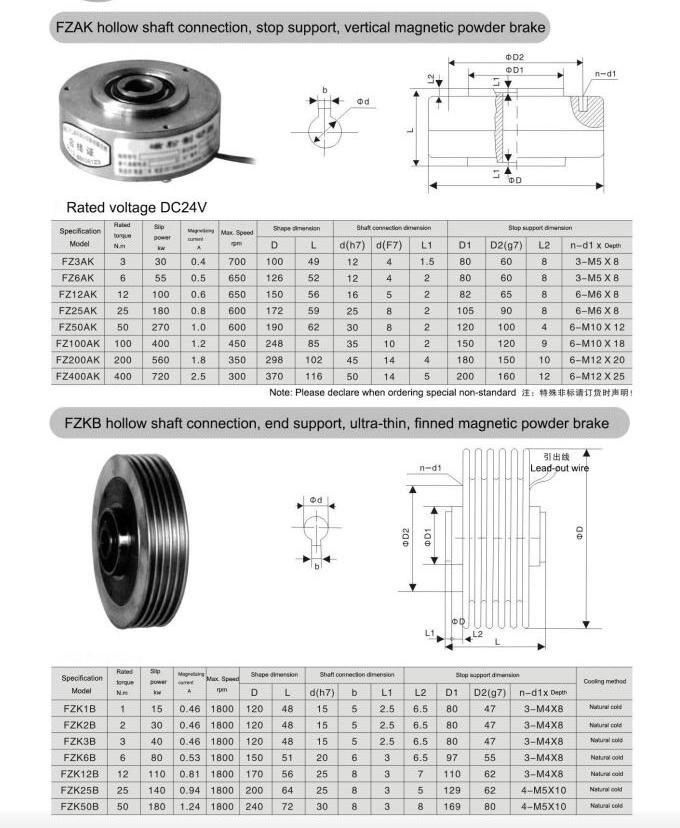

Size Information

Size Chart of This Design

|

Modle

|

Torque(N.m)

|

Current(A)

|

Votage(V)

|

Rotation speed

(RPM) |

Weight(kg)

|

|

ZA6A-1

|

6

|

0.8

|

24

|

1400

|

4

|

|

ZA12A-1

|

12

|

1

|

24

|

1400

|

6.5

|

|

ZA25A-1

|

25

|

1.5

|

24

|

1400

|

9.5

|

|

ZA50A-1

|

50

|

1.8

|

24

|

1400

|

15

|

|

ZA100A-1

|

100

|

2

|

24

|

1000

|

30

|

|

ZA200A-1

|

200

|

2.5

|

24

|

1000

|

55

|

|

ZA400A-1

|

400

|

3

|

24

|

1000

|

80

|

Related Products

Packing&Shipping

Packaging and ShippingWe regard packaging as a crucial link. Careful and appropriate packaging is fairly important to ensure the good condition and successful delivery of the belt conveyor idler rollers.

The following represents the most common practice:

· Wrap each roller with plastic film

· It is evacuated between the roller and the plastic film.

· Add desiccant.

· Bubble wrap.

· Plywood case

The following represents the most common practice:

· Wrap each roller with plastic film

· It is evacuated between the roller and the plastic film.

· Add desiccant.

· Bubble wrap.

· Plywood case

Company Introduction

Based on over 10 years experience in air shaft lines, ANHUI ZHELE MECHANICAL AND ELECTRICAL CO.,LTD was founded in 2006, is a production, design integration of the enterprise.

Using Taiwan professional production technology and advanced production equipment, professional production of face mask,face mask machine,Air expanding shaft(key type),Air expanding shaft(friction),Air expanding shaft(leaf type),shaft parts,aluminum roller with rotation shaft,aluminum roller with rotation shaft,aluminum roller without shaft,aluminum roller with stripe,safey chucks(flange type),safety chuk(slip type),safety chuk(pedeatal type),Electromagnetic Clutch,Air cluth,Air brake,Tension detector,EPC Edge Position Control,CPC Center position control,Tension detector,Automatic tension controller,Manual tension controller,Semi-Auto tension controller,Powder,Powder cluth,Powder brake,Electromagnetic clutch,Electromagnetic brake,etc.

Miraculously zhele Electromechanical, leading a few microns fine circles.

Using Taiwan professional production technology and advanced production equipment, professional production of face mask,face mask machine,Air expanding shaft(key type),Air expanding shaft(friction),Air expanding shaft(leaf type),shaft parts,aluminum roller with rotation shaft,aluminum roller with rotation shaft,aluminum roller without shaft,aluminum roller with stripe,safey chucks(flange type),safety chuk(slip type),safety chuk(pedeatal type),Electromagnetic Clutch,Air cluth,Air brake,Tension detector,EPC Edge Position Control,CPC Center position control,Tension detector,Automatic tension controller,Manual tension controller,Semi-Auto tension controller,Powder,Powder cluth,Powder brake,Electromagnetic clutch,Electromagnetic brake,etc.

Miraculously zhele Electromechanical, leading a few microns fine circles.

Our Services & Strength

Eight reasons to choose us:

1. Perfect service system and after-sale protection.

2. Quality problems will be solved within 24 hours.

3. One-to-one customer service tracking processing.

4. Companies carry out the ERP management, improve enterprise fast response.

5. Quality assurance, one year warranty.

6. Supporting professional matched other equipment.

7. The company has more than one product testing units, the implementation of ISO9001: 2015.

8. Unique development and design capabilities to meet the needs of special-purpose equipment manufacturing.

Five Core strengths:

1. The first domestic independent R & D manufacturer and 10 years of professional manufacturing.

2. Casting exquisite, beautiful, practical and durable.

3. Complete specifications, cost-effective and spot supply.

4. Independent research and development, special specifications can be customized.

5. Selected materials, high-tech treatment, up to the international standard test.

1. Perfect service system and after-sale protection.

2. Quality problems will be solved within 24 hours.

3. One-to-one customer service tracking processing.

4. Companies carry out the ERP management, improve enterprise fast response.

5. Quality assurance, one year warranty.

6. Supporting professional matched other equipment.

7. The company has more than one product testing units, the implementation of ISO9001: 2015.

8. Unique development and design capabilities to meet the needs of special-purpose equipment manufacturing.

Five Core strengths:

1. The first domestic independent R & D manufacturer and 10 years of professional manufacturing.

2. Casting exquisite, beautiful, practical and durable.

3. Complete specifications, cost-effective and spot supply.

4. Independent research and development, special specifications can be customized.

5. Selected materials, high-tech treatment, up to the international standard test.

FAQ

1.When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell your email, so that we can regard your inquiry priority.

2.How should I place an order?

Please let us know the model number based on our specs for powder clutch, powder brake, air clutch, air brake, electromagnetic clutch, electromagnetic brake and safety chucks, other transmission parts.

For air shafts,air adapter please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

3.What’s your MOQ basis?

Normally, we don’t have MOQ request, except the customized mini clutches/brakes.

4.What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller,which is about 3-5 days. For safety chucks, air shafts which need about 15-30 days.

5.What is the term of shipment?

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.

More concerned for our products , please do not hesitate to inquiry now!

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell your email, so that we can regard your inquiry priority.

2.How should I place an order?

Please let us know the model number based on our specs for powder clutch, powder brake, air clutch, air brake, electromagnetic clutch, electromagnetic brake and safety chucks, other transmission parts.

For air shafts,air adapter please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

3.What’s your MOQ basis?

Normally, we don’t have MOQ request, except the customized mini clutches/brakes.

4.What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller,which is about 3-5 days. For safety chucks, air shafts which need about 15-30 days.

5.What is the term of shipment?

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.

More concerned for our products , please do not hesitate to inquiry now!

After Sales Service

Hot Searches