- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

BOTTLING

-

Dimension(L*W*H):

-

1900*1500*2300mm

-

Weight:

-

3000 KG

-

Usage:

-

Can carbonated drinks / beer filling

-

Filling speed:

-

1500-20000 cans per hour

-

Control:

-

PLC (SIEMENS)+Touch Screen

-

Can type:

-

PET Aluminum Tin Can

-

Filling volume:

-

100ml-1000ml

-

Filling type:

-

Isobaric filling type

-

Material:

-

SUS304 / 316

-

Frame:

-

2 in 1(filling and sealing part)

-

Automatic grade:

-

Automatic

-

Certification:

-

CE ISO9001

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 2000BPH, 3000BPH

-

Packaging Material:

-

Plastic, Aluminum, Tin

-

Filling Material:

-

Beer, Other, Carbonated drink, Sofr drink, Sparking drink

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

BOTTLING

-

Dimension(L*W*H):

-

1900*1500*2300mm

-

Weight:

-

3000 KG

-

Usage:

-

Can carbonated drinks / beer filling

-

Filling speed:

-

1500-20000 cans per hour

-

Control:

-

PLC (SIEMENS)+Touch Screen

-

Can type:

-

PET Aluminum Tin Can

-

Filling volume:

-

100ml-1000ml

-

Filling type:

-

Isobaric filling type

-

Material:

-

SUS304 / 316

-

Frame:

-

2 in 1(filling and sealing part)

-

Automatic grade:

-

Automatic

-

Certification:

-

CE ISO9001

Products Description

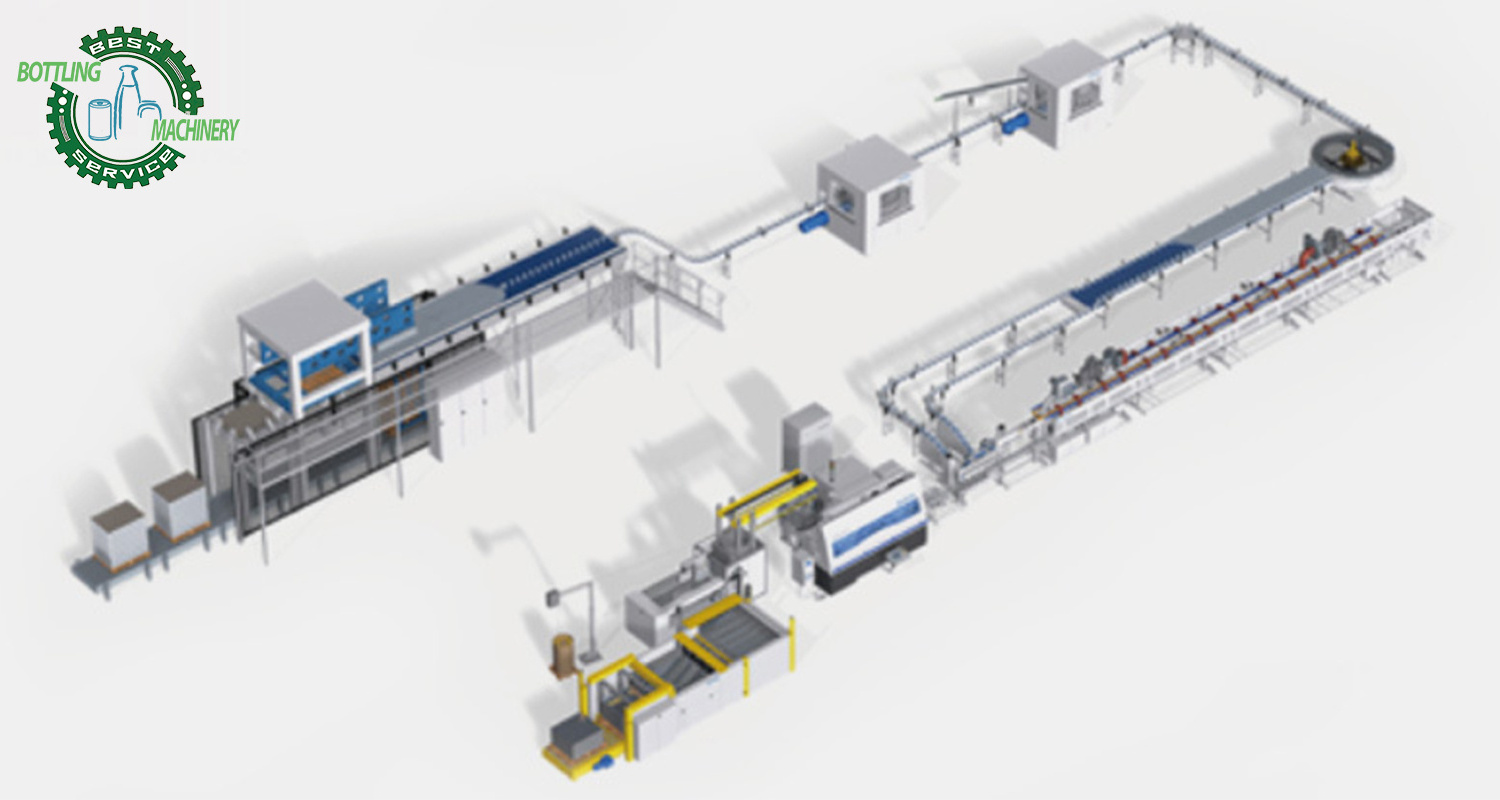

Aluminum can carbonated soft drink/beer filling line 1500CPH-20000CPH

The canned beverage production line mainly includes: water treatment equipment, beverage mixing system,

empty can

depalletizer, empty can washing machine, can filling and sealing machine, can warming machine, (sleeve labeling machine), blow dryer, can turning machine, code Machine, PE film heat shrink packaging machine or carton packaging machine.

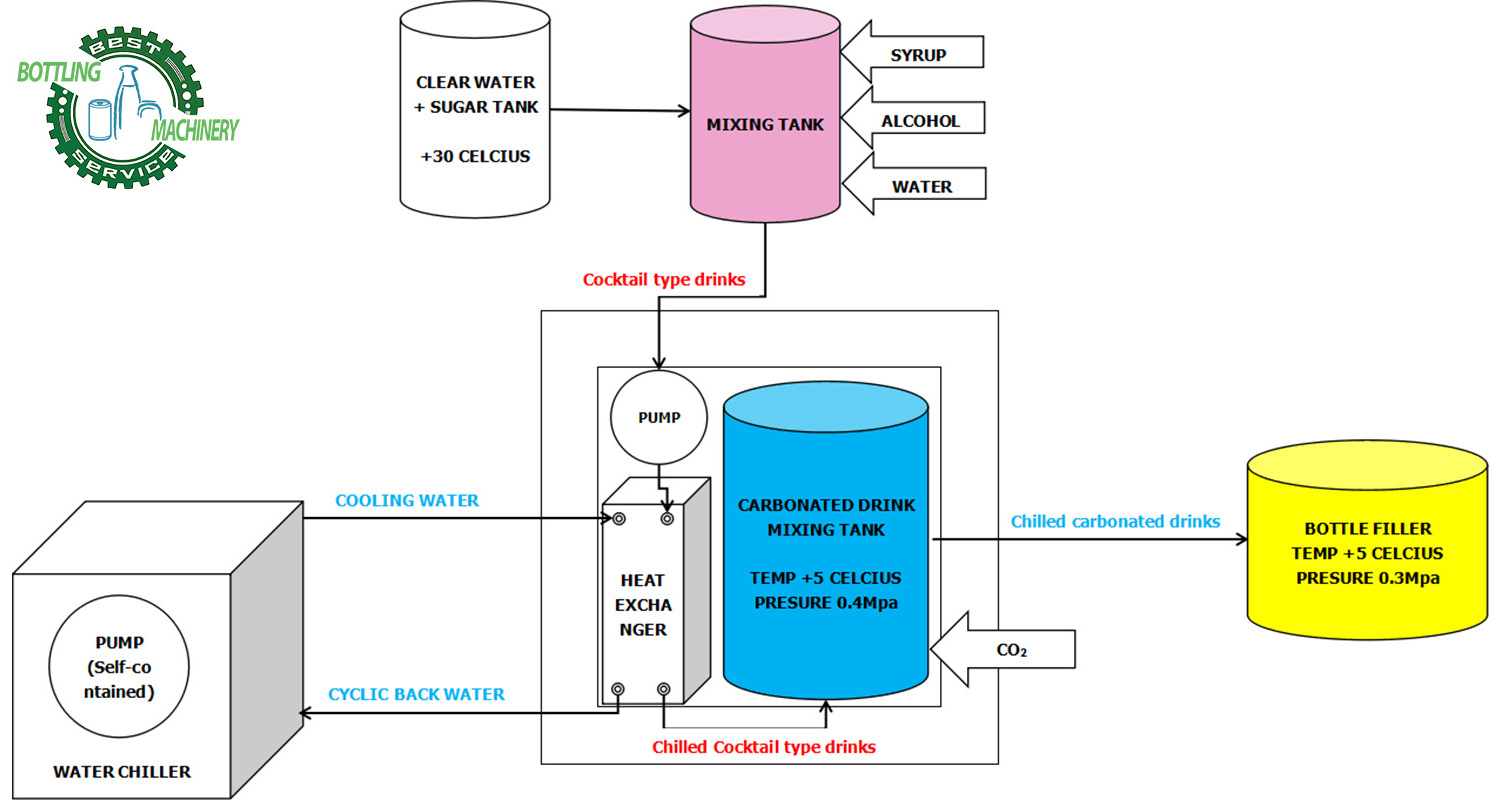

The carbonated drink mixing processing plant

Single tank

carbonator

,

double tank carbonator,

high ratio carbonator.

Syrup mixing, drinks cooling and CO2 mixing system:

Carbonated beverages are mainly composed of water, syrup, and carbon dioxide. The syrup is made through the sugar pot and the mixing tank. After filtration, it is pumped into the syrup tank in the carbonated drink mixer. At the same time, the sterilized finished water is also pumped into the beverage mixer. The water tank is vacuum degassed to facilitate the mixing of carbon dioxide. Through the proportioning system on the beverage mixer, the water and syrup are mixed in proportion to achieve the desired taste, and our mixer incorporates carbon dioxide jet technology, The sandy taste of the beverage is equivalent to Coca-Cola, and the mixed materials are cooled by a plate heat exchanger, where the other end of the plate heat exchanger is mainly connected with a water chiller (cold water is provided, with antifreeze added, and the water outlet temperature is -3℃ -8°C adjustable) connection, we will select the chiller based on the user’s local climatic conditions. Through this heat exchange method, the material can be cooled to 0°C~3°C and fed into the beverage mixer. The carbon dioxide mixing tank can dissolve carbon dioxide into the material under the control of proper pressure to make carbonated beverages with ideal gas lock capacity.

CIP Separate alkali, acid tank, hot water tank;

Heating pipes used for cleaning liquid heating by steam connection or hot water boiling recycling;

Centrifugal pump to discharge cleaning liquid to the machines which need to be washed;

Feedback pump can be added for cleaning liquid recycling;

It is for easy equipment s cleaning, divided into 5 steps of cleaning:A, Pre-Hot Water cleaning B, Alkali cleaning C, Post-Hot Water cleaning D, Acid cleaning E, Post-Hot Water cleaning

Automatic can depalletizer:

1, The depalletizer is the first step of the can production line. The entire can stack is unloaded one by one to the conveyor by the depalletizer to prepare for the subsequent filling, saving labor.

2, If it is an aluminum can, it is matched with a screw auger washing machine. The cans on the depalletizer are turned over by the screw auger until the mouth of the can is upward and enters the can washing machine in an orderly manner. The inside of the can is cleaned and then filled. Pack and seal to the back packaging. If it is a tinplate can, it can be transported through the screw auger for filling.

3, The main working process of the depalletizer is: the can stack is shoveled by a forklift (or hydraulic truck) to the positioning on the loading conveyor, PLC is automatically controlled throughout the whole process, the can stack is driven by the chain to be sent to the hanging basket, and the can stack is placed in the hanging basket. When the empty tank on the tank stack blocks the radiation of the through-beam photoelectric switch, the lift stops. At this time, the position of the first layer of tank bottom is exactly on the same plane as the transport plane of the buffer platform. Next, the empty tank is sent to the buffer platform under the action of the tank pushing plate, and the tank pushing cart to the designated position (controlled by the proximity switch). After a short pause, reverse and return to the initial position. So back and forth. When the proximity switch that detects the gondola detects a signal, the gondola descends until it reaches the bottommost position, so that the second stack can be unstacked again. The speed of buffer conveying and rapid conveying can be adjusted by stepless speed regulator to adapt to the production speed of the entire production line.

4, The output is 10,000-20000 cans per hour.

Can washing machine:

It automatically sprays and sterilizes the inner cavity and outer surface of the can. The material is stainless steel. When flushing the cans, first turn the cans into the can washer, spray down a warm water pipe with a porous, and then rotate 0.5 meters to achieve the purpose of cleaning, and then extend the cans to slide into the next conveyor chain. road. It is necessary to pay attention to the tank not to be interrupted in the chute to prevent the fast irrigation speed and the unclean water control.

Can Filling Sealing machine:

1, The filling equipment for canned beverages adopts the principle of equal pressure filling. When the empty can enters the lifting tray via the dial, the filling valve and the empty can are centered, the empty can is lifted and sealed, and the valve of the filling valve is automatically opened at the same time When the filling liquid level blocks the valve's return pipe mouth, the filling will be stopped. The filled can is sent to the sealing machine head through the hook chain, and the lid is sent to the can mouth by the cap feeder and the pressure head. When the can supporting mechanism is raised, the pressure head presses the can mouth, and the sealing wheel is pre-sealed and then solidified. After the can is sealed, it is pushed out by the head of the capping mechanism, and then enters the delivery of the can.

2, The can filling production line adopts PLC, frequency converter, and man-machine interface control system. It has control technology such as frequency conversion speed regulation, automatic filling with cans, and no filling without cans. Through various sensors on the equipment, the accurate production speed and production quantity can be displayed on the touch screen. The production speed can be set on the touch screen according to user requirements. The whole machine has various protections for the main motor and other electrical appliances, such as overload and overvoltage. At the same time, various faults will be automatically displayed on the touch screen, which is convenient for users to find the cause of the fault.

Filling part:

304/316 Stainless steel high precision filling nozzle.Filling volume adjustable in fine rank, same liquid level after filling All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

Capping part:

The capping head adopts constant magnetic torque device to ensure the high capping quality without damage. High efficient cap settling system, cap feeding system and no bottle no cap system make the whole capping system perfect.

|

Technical parameter of all our can carbonated drink filling machine:

|

|

|

|

|

|

|||||

|

Model

|

Linear 12-1

|

DG12-1

|

DG18-4

|

DG24-6

|

DG36-6

|

|||||

|

Capacity(cans/hour)

|

1000-1500

|

1000-2000

|

3000-6000

|

4000-9000

|

6000-15000

|

|||||

|

Can material

|

PET / aluminum

|

7000BPH

|

5.2KW

|

2450*2100*2400mm

|

|

|||||

|

Can diameter

|

DN52.9*99mm

|

12000BPH

|

5.2KW

|

2750*2400*2400mm

|

|

|||||

|

Can height

|

39-160mm

|

|

|

|

|

|||||

|

Filling type

|

Isobaric filling

|

15000BPH

|

7KW

|

3350*2680*2400mm

|

|

|||||

|

Filling pressure

|

<0.4 Mpa

|

20000BPH

|

7KW

|

3860*3150*2400mm

|

|

|||||

|

Can volume

|

100ml-1000ml

|

24000BPH

|

8KW

|

4500*3500*2400mm

|

|

|||||

|

Application

|

carbonated beverage / soft drink / beer filling machine

|

1500BPH

|

5.2KW

|

2500*2100*2100mm

|

|

|||||

|

Total power

|

3kw

|

4.5kw

|

5kw

|

6.5kw

|

7.2kw

|

|||||

|

Dimensions(m)

|

2.5*1.9*2.3m

|

1.75*1.14*1.9

|

2.32*1.4*1.9

|

2.58*1.68*1.9

|

3.66*2.53*1.9

|

|||||

|

Weight

|

2500kg

|

3100kg

|

3800kg

|

4400kg

|

5000kg

|

|||||

Stainless Steel Carbonated Drinks Spraying Can Warming Tunnel

This machine is used for carbonated beverages. Because the filling temperature is 0-4 degrees Celsius and the ambient temperature is 20-30 degrees, The bottle warming machine adopts a three section steam recycling heating design,the water spraying water temperature shall be controlled around 40 degrees. After the bottle go out, the temperature will be around the 25 degrees. Users can fix the temperature according to need. All the end of the warmer, it is equipped with the drying machine to blow the water outside the bottle. It is equipped with the temperature control system. Users can adjusted the temperature by himself

Main features:

The conveyor is frequency controlled.

All nozzle and spray tubes are made of stainless steel and spray evenly

The catchment flume is made of stainless steel and equipped with a level alarm device

The spray tunnel has a spray cooling recycling water pump and steam adjustment valve

Steam consumption is adjusted according to the temperature.

For the whole can filling line, there are some

necessary

machines

you still need equip:

RO water treatment machine

Bottle blow molding machine

Bottle blow dryer

Bottle labeling machine

Code printer

Film shrink packing machine

company profile

ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. is located in Zhangjiagang city which is core of beverage machinery producer collection in China. Integrated the industry advantages and its own development in R&D, production, sales, after sales service,

BOTTLING MACHINERY is ready to serve more and more customers with our full range products and best service.BOTTLING MACHINERY is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

BOTTLING MACHINERY is ready to serve more and more customers with our full range products and best service.BOTTLING MACHINERY is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

We are the supplier who can design and manufacture for all kinds beverage production plant (pure drinking water, mineral water,carbonated drinks, juice, tea and beer, etc.)

Customer's service:

1. ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. can provide turn-key project for you, we can design the beverage factory plan according to your idea.

2. BOTTLING MACHINERY company have professional design team, our engineers can draw bottle samples and flow chart of workshop for you .

3. BOTTLING MACHINERY company can give you the best quotation for all kinds of beverage production, as long as you tell us which kind of drink you want to produce, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass bottle or can, etc.

After service:

1. We send our engineers to your factory to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the goods shipping to you:

a. Machines layout drawing.

b. Electricity diagram.

c. Machine certificate.

d. General manual book/maintenance book.

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.

1. ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. can provide turn-key project for you, we can design the beverage factory plan according to your idea.

2. BOTTLING MACHINERY company have professional design team, our engineers can draw bottle samples and flow chart of workshop for you .

3. BOTTLING MACHINERY company can give you the best quotation for all kinds of beverage production, as long as you tell us which kind of drink you want to produce, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass bottle or can, etc.

After service:

1. We send our engineers to your factory to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the goods shipping to you:

a. Machines layout drawing.

b. Electricity diagram.

c. Machine certificate.

d. General manual book/maintenance book.

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.

Packing&Delivery of BOTTLING

1. Our machines are packed by wooden case.

2. The delivery date of this machine is within 10-25 days after payment.

FAQ

Q:Are you a manufacturer or trade company?

A:We are a manufacturer in beverage bottling machine field more than 10 years, located at Leyu town, ZhangJiaGang, 2 hours from Shanghai, We will pick you up from Shanghai

Pudong Airport

to visit our factory.

Q:Do you have any certification?

A:SGS,ISO,CE etc

Q:What about the delivery time?

A:Usually 20-30 Working days for most kinds of machines

Q:What about the machine’s capacity?

A:1000 - 20000 bottles

per hour

based on 500ml bottle.

Q:The after-sale service

A:12 months warranty.

We can solve basic questions by telephone, email, whatsapp, wechat and video call.

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

Operating manuals will be sent with machines or by email.

We also have overseas service center

Q:If our bottle size changes, can we just do some adjustment on machine according to our new bottle?

A:Yes. Maybe you just need some spare little parts to change.

Q: If I want to purchase the machine, what information do I need to tell you?

A:a. What kind beverage you want to produce?

b. bottle volume? 250ml, 330ml, 500ml, 750ml, etc.?

c. Producing capacity requirement? How many bottles per hour?

d.Raw water analysis report .

e.Voltage and altitude.

Q:What kinds of product you supply?

A: Drink water/juice/carbonated drink filling line for bottle or can.

5 gallon/20L bottle water filling line.

Water treatment system.

Bottle blowing molding machine.

After packing system(label machine, PE film shrink packing machine, carton machine)

Sachet water packing line

Contact us

MS YOLANDA

5 years’ experience in foreign trade sales

Major in International business at

Yantai University

Whatsapp/Wechat: +8615190564896

Email:

yolanda@zjgbottlingmachinery.com

MR PHIL LANE

8 years’ experience in foreign trade sale

Major

Architecture, skilled CAD drawing, physical structure

China College English Test-6

Whatsapp/Wechat: +8615737466736

EMail: admin@zjgbottlingmachinery.com

EMail: admin@zjgbottlingmachinery.com

MR

ANDY

6 years in foreign trade sales

Major in mechanical engineering at university

Proficiency in photoshop drawing

Whatsapp/Wechat: +8613306249269

Email: sales1@zjgbottlingmachinery.com

Email: sales1@zjgbottlingmachinery.com

Hot Searches