- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

1.2%~1.4%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

JM

-

Brand Name:

-

Topower

-

Product name:

-

lightweight clay insulation brick

-

CLASSIFICATION TEMP:

-

1300℃

-

THERMAL EXPANSION:

-

0.5

-

Keyword:

-

Thermal Insulating Clay firebrick

-

Apparent Porosity:

-

20-23%

-

Bulk Density:

-

0.6G/CM3

-

CRUSHING STRENGTH:

-

1.2MPA

-

MODULUS OF RUPTURE:

-

1.0MPA

-

Usage:

-

Refractoy

-

Application:

-

Industrial Furnaces

Quick Details

-

SiO2 Content (%):

-

International Standard

-

Al2O3 Content (%):

-

40%

-

MgO Content (%):

-

0.18%

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

1.2%~1.4%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

JM

-

Brand Name:

-

Topower

-

Product name:

-

lightweight clay insulation brick

-

CLASSIFICATION TEMP:

-

1300℃

-

THERMAL EXPANSION:

-

0.5

-

Keyword:

-

Thermal Insulating Clay firebrick

-

Apparent Porosity:

-

20-23%

-

Bulk Density:

-

0.6G/CM3

-

CRUSHING STRENGTH:

-

1.2MPA

-

MODULUS OF RUPTURE:

-

1.0MPA

-

Usage:

-

Refractoy

-

Application:

-

Industrial Furnaces

Clay insulation brick introduction

According the shape, Clay insulation brick can be divided into standard brick, special-shaped brick.

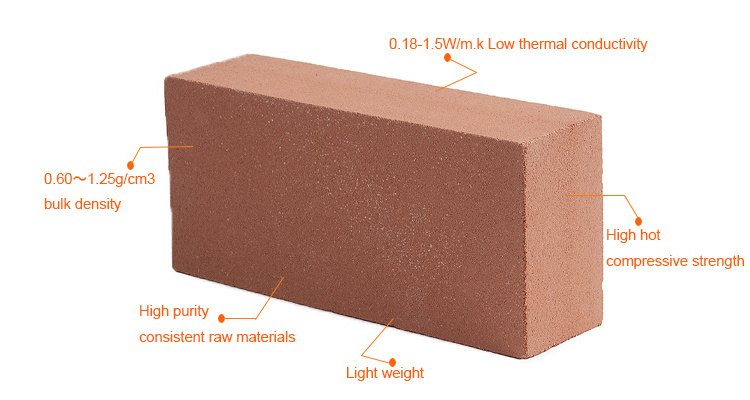

The bulk density of lightweight heat-insulating brick is 0.60~1.25g/cm3. Working temperatures range from 900℃ to 1600℃ Good thermal shock resistance.

Topower series lightweight heat-insulating bricks are made from good quality and super-pure raw materials, with strictly classified fillings according to their grades.this material profitable by lessening fuel costs, construction costs and reducing the amount of time spent in the high temp furnace.

Product Paramenters

|

Brand

Properties

|

B-1

|

B-2

|

B-3

|

B-4

|

B-5

|

||||

|

≤ 2.0% Reheating Shrinkage Temp (℃)

|

900

|

1,000

|

1,100

|

1,200

|

1,300

|

||||

|

Bulk Density (g/cm3)

|

0.70

|

0.70

|

0.75

|

0.80

|

0.80

|

||||

|

(kg/cm2) Cold Crushing Strength

|

25

|

25

|

25

|

25

|

25

|

||||

|

(W/m.k) at 350℃ Thermal conductivity

|

0.17

|

0.18

|

0.20

|

0.22

|

0.23

|

||||

|

Brand Properties

|

B-6

|

B-7

|

C-1

|

C-2

|

C-3

|

||||

|

≤ 2.0% Reheating Shrinkage Temp (℃)

|

1,400

|

1,500

|

1,300

|

1,400

|

1,500

|

||||

|

Bulk Density (g/cm3)

|

0.90

|

1.00

|

1.10

|

1.20

|

1.25

|

||||

|

(kg/cm2) Cold Crushing Strength

|

30

|

30

|

50

|

70

|

100

|

||||

|

(W/m.k) at 350℃ Thermal conductivity

|

0.27

|

0.31

|

0.30

|

0.38

|

0.45

|

||||

|

Main Applications

|

Ceramic Roller Kiln Reheating

Reheating Furnace Blast Furnace Petrochemical Furnace General Industrial Furnace etc. |

|

|

|

|

||||

Recommend Products

Topower is the leading supplier of high-grade refractory products, systems and solutions which are indispensable for industrial high-temperature processes exceeding 1,200°C in a wide range of industries furnace, including steel, cement, non-ferrous metals and glass etc.

Q1 : Are you a manufacture or trader?

A1: We are truly a manufacturer, we not only can provide the high quality products with the best price, but also can offer the best pre-sale service and after-service.

Q2: How can you control your quality?

A2: TOPOWER have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

Q3 : Do you supply samples?

A3 : Of course, free samples are available.

Q4 : What is your lead time?

A4 : It usually needs about 15- 20 days after receiving the PO.

Q5 : Can we visit your company?

A5 : Yes, for sure, you are welcome to visit TOPOWER company and our products.

Also, we can talk more about the technique details if you need.

Q6 : What is the warranty of your products?

A6 : Our products have at least 1 year warranty,if any quality problems,

we will take responsibility of the cost of the shipment and the replacement.

Hot Searches