- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, or customized

-

Power:

-

70KW

-

Dimension(L*W*H):

-

25000*1500*2100MM

-

Weight:

-

3500 KG

-

Marketing Type:

-

New Product 2023

-

Name:

-

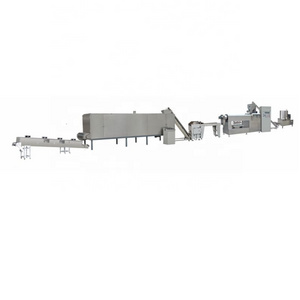

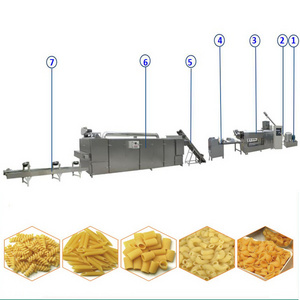

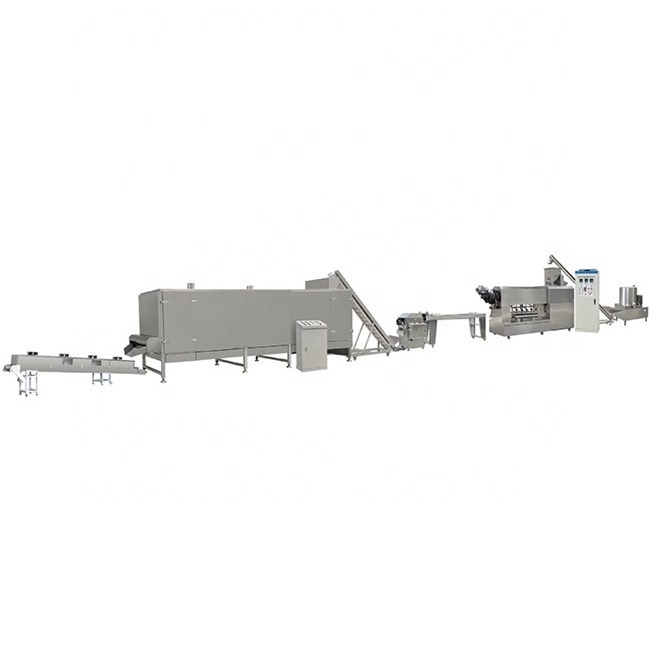

Italian Macaroni Penne Fusilli Shells Pasta Making Machine

-

Function:

-

Fully Automatic High Efficiency Processing Line

-

Product name:

-

Spiral shell straight hollow oblique cut hollow noodle etc.

-

Application:

-

Food Industry Machinery

-

Keywords:

-

Pasta Macaroni Spaghetti Machine

-

Raw material:

-

Wheat Flour Dough

-

Capacity:

-

80-250kg/h

-

Material:

-

Food Grade Stainless Steel

-

Install Power:

-

105kw

-

actual power:

-

70kw

Quick Details

-

Type:

-

Italian Macaroni Pasta Processing Line

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MEST

-

Voltage:

-

380V, or customized

-

Power:

-

70KW

-

Dimension(L*W*H):

-

25000*1500*2100MM

-

Weight:

-

3500 KG

-

Marketing Type:

-

New Product 2023

-

Name:

-

Italian Macaroni Penne Fusilli Shells Pasta Making Machine

-

Function:

-

Fully Automatic High Efficiency Processing Line

-

Product name:

-

Spiral shell straight hollow oblique cut hollow noodle etc.

-

Application:

-

Food Industry Machinery

-

Keywords:

-

Pasta Macaroni Spaghetti Machine

-

Raw material:

-

Wheat Flour Dough

-

Capacity:

-

80-250kg/h

-

Material:

-

Food Grade Stainless Steel

-

Install Power:

-

105kw

-

actual power:

-

70kw

Product Description

Specification

Process flow:

Raw material preparation → mixing → extrusion molding → shaping and cutting → conveying → drying → cooling → (packing)

The hollow pasta machinery and equipment use corn starch and potato starch as the main raw materials, and use a unique extrusion molding process to achieve the best sensory effect on the product shape. The product shape is natural and lifelike, with a delicate texture, a loose taste and no cracking. The production line has reasonable design, strong stability and high degree of automation. The host adopts advanced frequency conversion speed regulation technology, which is highly efficient and energy-saving. Precise parameter control and perfect technological process ensure the stable quality of processed products. The products include spiral noodles, shell noodles, straight hollow noodles, curved hollow noodles, oblique cut hollow noodles, wheel noodles, soaked noodles, etc. dozens of options are available.

|

Model

|

MST-85

|

MST-90

|

|

Voltage

|

380V/50HZ

|

380V/50HZ

|

|

Power

|

70KW

|

82KW

|

|

Install Power

|

105kw

|

146KW

|

|

Capacity

|

80-150kg/h

|

180-250kg/h

|

1. Flour mixing machine

The powder mixer is a machine for mixing raw materials, auxiliary materials, water and other materials to mix evenly.

Part of the material contacting the product is made of stainless steel.

The discharge hole adopts a new treatment opening design, which is well sealed to avoid leakage of materials.

High motor speed, double-layer stirring rod, uniform stirring, short time and low energy consumption.

2.

elevator

Use the screw mechanism to lift the raw material mixed by the mixer to the main feeder.Uniform speed feeding, save labor.

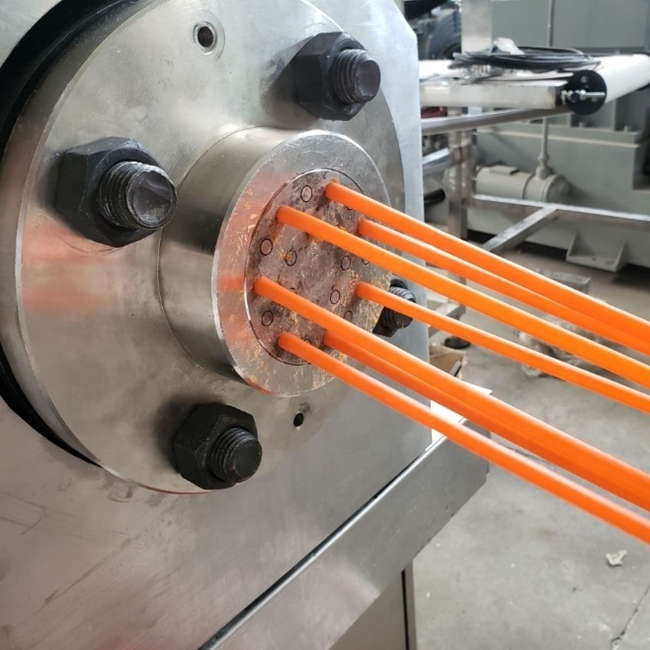

3. Single screw extruder

1. Use advanced frequency control skills, work stably and consume less power;

2. Screw made of alloy steel, with longer service life;

3. Automatic heating control system, easy to work and more accurate parameters.

4. The equipment is equipped with water cycle temperature control system.

5. Feed motor, host motor and rotary cutting motor all adopt frequency conversion speed regulation.

6. The extruder achieve secondary curing, and the product curing effect is good.

4. Traction cutting machine

1. The cutter is used to cut rectangular and round pipes. Bevel straight pipe and straight cutting machine.

2. The traction cutting machine has two parts: cutting system and conveying system.

3. The operation of the equipment is simple, and the length of frequency control can be adjusted.

4. This cut is specially designed for macaroni.

5 elevator

1. The hoist conveys the food from low to high, according to the process; The inlet of the drying box determines the height and horizontal distance of the hoist

2. The conveying adopts food grade, and the frame is made of stainless steel

3. The conveyor belt of hoist is equipped with leakproof material retaining device.

4. The hoist is fixed speed feeding.

6. Drying box (hot air circulation oven )

Hot air drying box after practical experience and product characteristics of professional design for macaroni to make drying box.

1. The oven has compact structure, small occupation area and economic applicability.

2. The net belt and protection plate are all made of food-grade stainless steel, to ensure that the material is qualified.

3. The operation speed of the oven is controlled by frequency conversion, with smooth operation and long-term use.

4. The temperature is controllable, and the precise temperature probe is installed in the zone controlled by heating (constant temperature zone, heating zone, preheating zone) to ensure the temperature error is small and affect the product.

5. Heating mode heating tube, heating tube through special customized configuration of heat sink, to achieve the best performance.

6. The net belt adopts both sides of the chain drive, net belt support rod after bolding, to ensure longer service life.

7. Layer and layer connecting section through the material baffle device to prevent leakage, the lowest end of both ends are set off the material storage box, easy to clean.

8. High speed fan is used in the drying box, and the wind speed circulation device is set in the oven to make the wind speed flow fast and speed up drying.

10. Drying set dehumidification system, is the effective discharge of moisture air.

11 drying belongs to low temperature multi-layer circulating drying box, indirect heating. High drying requirements for macaroni products, high temperature, short shelf life, cracks, bubbles on the surface, bad appearance, easy to spread out when boiled.

12. This drying box can also dry nutritious rice, lemon slices, dried fruit, Chinese herbal medicine and other products requiring high technology for drying.

7. Cool the conveyor

Used to transport food to the next stage.

Related Products

Packing & Delivery

Hot Searches