- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

10000 KG

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Product name:

-

Hot Sale Automatic Carton Board Folder Glue 4 6 Corner Gluer Machine

-

Name:

-

Paper Box Crash Lock Bottom Carton Box Flexo Folder Gluer

-

Box forming:

-

4/6 Corner Box

-

Usage:

-

Corrugated Paperboard Folding Gluing

-

Function:

-

Paper Cardboard Box Gluing Machine

-

Feeding way:

-

Continuously Feeding

-

Speed:

-

260m/min

-

Advantages:

-

Long Working Life

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

15000*2350*1650mm

-

Weight:

-

10000 KG

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Product name:

-

Hot Sale Automatic Carton Board Folder Glue 4 6 Corner Gluer Machine

-

Name:

-

Paper Box Crash Lock Bottom Carton Box Flexo Folder Gluer

-

Box forming:

-

4/6 Corner Box

-

Usage:

-

Corrugated Paperboard Folding Gluing

-

Function:

-

Paper Cardboard Box Gluing Machine

-

Feeding way:

-

Continuously Feeding

-

Speed:

-

260m/min

-

Advantages:

-

Long Working Life

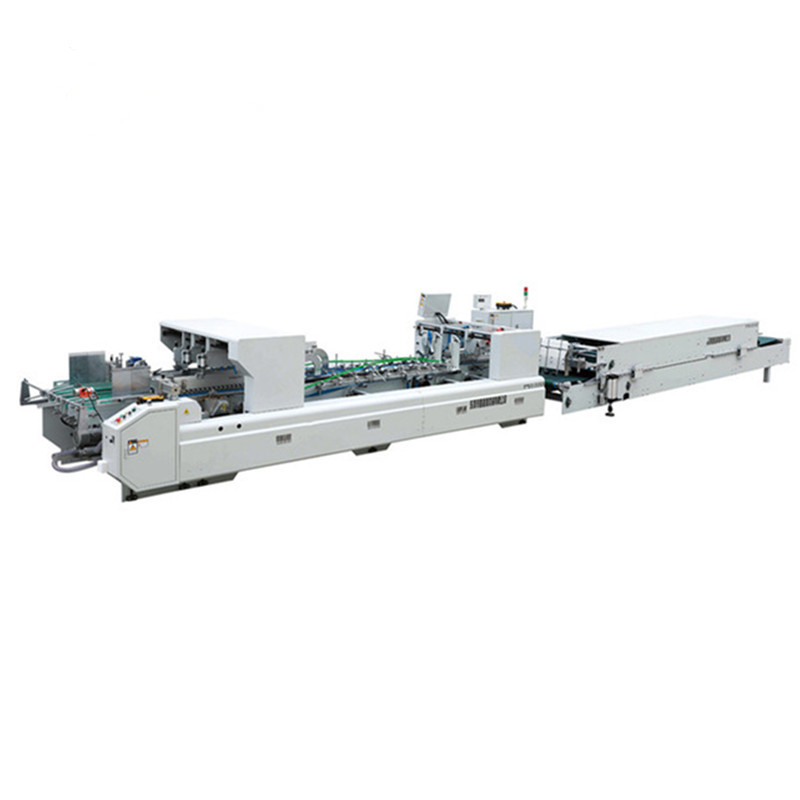

Hot Sale Automatic Carton Board Folder Glue 4 6 Corner Gluer Machine

| Introduction |

1. Automatic gluing and folding machine and it consist of vacuum adsorption feeding part, gluing and folding part and stacking and counter part.

2. It adopts frequency to change speed and controlled by standard PLC touch screen, easy operation and reliable.

3. High speed and energy-saving and save labor.

4. It is suitable for the paper, corrugated paperboard with 3,5 layer.

5. The feeding unit of the machine has the paper board stack to hold the paperboard which helps to improve the production efficiency and it also adopts the air sucking structure to improve transport efficiency and accuracy.

6. Connecting unit adopts hot melt adhesive, four side gauge positioning to ensure accurate register and high precision.

7. The machine major motor and conveyor adopt dual frequency for speed control. Stable and saved energy.

|

| Detailed Images |

|

|

|

|

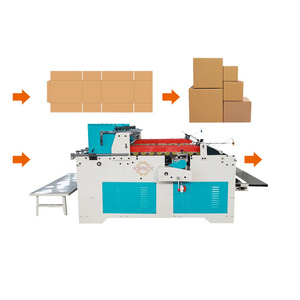

Guiding section It can correct deviation of feeding effectively, when deviated box get to guide will be corrected, adjust the left or right side based on the box shape. |

|

|

|

Pre-folding section This device pre-fold first and third line, make the box more easy to open and fold. |

||

|

Folding section It folds second and fourth which is the last part of the box forming, box forming is folded by upper pressure conveyor belt, folding knife, pressure roller, pressure bar. |

||

|

|

Full pressing section Pressure connect between main machine and transmission, collect the box orderly and guide the box to conveyor device. |

| Parameters |

|

Model |

UG1-1450PC |

UG1-1450AC |

|

paper |

Card board, corrugated board |

Card board, corrugated board |

|

Feeding way |

Automatically ,continuously |

Automatically ,continuously |

|

Speed |

260m/min |

260m/min |

|

Overall dimension |

17000×2350×1650mm |

15000×2350×1650mm |

|

Weight |

12t |

10t |

|

Power |

20.5kw |

18.5kw |

|

Model |

UG-1450PC/AC |

|

A MAX |

1500mm |

|

A MIN |

300mm |

|

B MAX |

1500mm |

|

B MIN |

80mm |

|

C MAX |

730mm |

|

C MIN |

140mm |

|

D MAX |

350mm |

|

D MIN |

20mm |

| Packing and Shipping |

Packaging details: Covered with plastic film, a dopts moisture-proof and shock-proof packaging.

| Our Services |

| FAQ |

1. Q: Are you a factory or trading company?

A: We are a company owned our factory which is specialized in the production of various kind of carton equipment. (With export license)

2. Q: How can I visit your factory?

A: We can pick you up if you need, welcome to visit our factory.

3. Q: What are your products?

A: We are specialized in producing 3ply, 5ply, 7ply corrugated cardboard production line, high speed printing machine, ordinary printing machine, creasing and die cutting machine,folder gluer,flute laminator,stitching&strapping machine and other corrugated

cardboard production equipments.

4. Q: How does your factory do regarding quality controlling?

A: Over the years our company take “the quality first” “integrity-based” corporate purpose always meet users’ requirements as our sole purpose, providing the products with excellent quality, professional technology. Always attach great importance to quality controlling from the very beginning to the very end.

a. All raw material we used are environmental-friendly.

b. Skillful workers care every detail in handling the producing and packing process.

c. Quality control department especially responsible for quality in each process.

5. Q: How is the evaluation of the products?

A: Products are distributed in Russia, the Middle East, Africa, Southeast Asia, EU and other countries and throughout the country. Product quality and enterprise reputation get the high praise at home and aboard.

6. Q: What is the payment term?

A: 30% deposit will be paid within 3 days after the contract is signed, and the remaining 70% will be paid before shipment.