- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1000w

-

Dimension(L*W*H):

-

Depands on models

-

Weight:

-

1000 KG

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TAIKANG

-

Voltage:

-

220V

-

Power:

-

1000w

-

Dimension(L*W*H):

-

Depands on models

-

Weight:

-

1000 KG

Products Description

Product Paramenters

|

Sr.

|

Evaporation Rate(kg/h)

|

Weight(kg)

|

Power(kw)

|

Material

|

|

1

|

1000

|

7000

|

31.5

|

316L

|

|

2

|

1500

|

9000

|

35.5

|

316L

|

|

3

|

1956

|

15000

|

42.5

|

2205,316L

|

|

4

|

4170

|

13000

|

37

|

304

|

Our Advantages

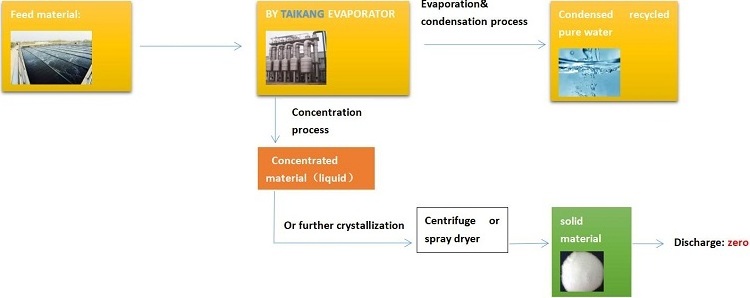

1. Material: SUS304 or SUS316L or Titanium

2.Full closed process, fast and low temperature evaporation;

3.Inside pipes are mirror polishing seamless sanitary pipes, so material is not easy to paste on the pipe all, it's easy for

cleaning;

4.Low steam consumption: 1kg steam can evaporate 3.5kg water;

5.Low evaporation temperature:part of secondary steam can be inhaled into single-effect heater through spray type hot pressure pump, this would make full use of the heat and the evaporation temperature is low.

6.Large concentration ratio: adopt falling film evaporation, which make the material liquid with larger viscosity be easy to flow and evaporate, hard to scale, short concentration time, the concentration ratio can reach to 1:5.

7.This equipment can realize automatic production, intellectual system management, which is in conformity with GMP standard.

8.Can be desiged into different technological process according to the different characteristics of the materials , also can

according to different users' requirements equip with automatic control system.

2.Full closed process, fast and low temperature evaporation;

3.Inside pipes are mirror polishing seamless sanitary pipes, so material is not easy to paste on the pipe all, it's easy for

cleaning;

4.Low steam consumption: 1kg steam can evaporate 3.5kg water;

5.Low evaporation temperature:part of secondary steam can be inhaled into single-effect heater through spray type hot pressure pump, this would make full use of the heat and the evaporation temperature is low.

6.Large concentration ratio: adopt falling film evaporation, which make the material liquid with larger viscosity be easy to flow and evaporate, hard to scale, short concentration time, the concentration ratio can reach to 1:5.

7.This equipment can realize automatic production, intellectual system management, which is in conformity with GMP standard.

8.Can be desiged into different technological process according to the different characteristics of the materials , also can

according to different users' requirements equip with automatic control system.

Hot Searches