- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

BOTTLING

-

Dimension(L*W*H):

-

1360*700*1820mm

-

Weight:

-

150 KG

-

Product name:

-

Semi auto 2/4 head carbonated drink filling sealing machine

-

Filling speed:

-

0-1000 cans per hour

-

Container type:

-

Can

-

Can volume:

-

180-500ml

-

Filling type:

-

Isobaric filling type

-

Air pressure:

-

0.3-0.6Mpa

-

Air consumption:

-

0.05m3/min

-

Automatic grade:

-

Semi-automatic / Manual

-

Material:

-

SUS304

Quick Details

-

Machinery Capacity:

-

500BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal

-

Filling Material:

-

Beer, Other, carbonated drink, soft drink, soda water, sparking water, spirit

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

BOTTLING

-

Dimension(L*W*H):

-

1360*700*1820mm

-

Weight:

-

150 KG

-

Product name:

-

Semi auto 2/4 head carbonated drink filling sealing machine

-

Filling speed:

-

0-1000 cans per hour

-

Container type:

-

Can

-

Can volume:

-

180-500ml

-

Filling type:

-

Isobaric filling type

-

Air pressure:

-

0.3-0.6Mpa

-

Air consumption:

-

0.05m3/min

-

Automatic grade:

-

Semi-automatic / Manual

-

Material:

-

SUS304

Products Description

Semi auto filling and sealing machine for beer and carbonated drink 1000BPH

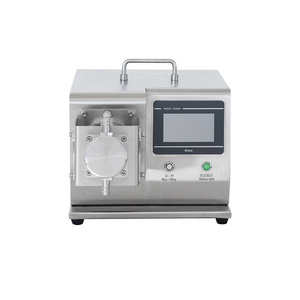

Semi auto balance pressure Filling Machine for Can

|

Product name

|

Semi-auto filling machine

|

|

Model:

|

BZDG-4A

|

|

Filling range:

|

180-500ml

|

|

Air pressure

|

0.3-0.6Mpa

|

|

Air consumption

|

0.05m3/min

|

|

Precision:

|

99%

|

|

Capacity:

|

1000BPH(for 500ml)

|

|

Suitable bottle

|

Height: 120-360mm, diameter: 30-105mm

|

|

Power:

|

0.1KW

|

|

Size:

|

1360*700*1820mm

|

|

Weight:

|

150kg

|

Optional Feature:Rinser loading for Cans

In order to meet higher hygiene standards and product quality requirements, our semi-automatic carbonated beverage can filling and sealing machine can additionally add can inner rinsing function. By adding this rinsinging function, our machine will achieve an integrated operation of rinsing-filling-sealing, making the entire production process more efficient and seamless.

Detail of Can Filling Head: Ensuring Accurate and Precise Beverage Filling

This semi-automatic carbonated beverage can filling machine is equipped with an efficient and reliable filling head. The filling head uses advanced technology to accurately control the filling process, ensuring that each can is injected with the appropriate amount of carbonated beverage accurately.

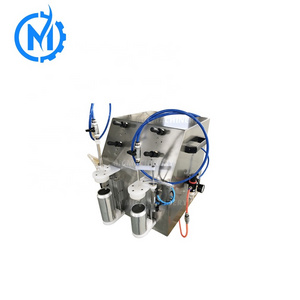

Semi auto

2 head

Sealing Machine

Manual holding a can to put on support base, press start, then the can will be lift up to sealing head, the sealing wheel on the lift side will be close to the press head, the sealing wheels will start to seal at the meantime, and the sealing wheel will leave until the first edge curl work finished, then the sealing wheel on the right side will go to finish the second edge curl work to form the sealing, then one can will be sealed. The seaming effect is good. By adjusting support height, the can height can be adjusted. By changing support base and sealing head, different diameter can will be sealed.

The machine is driven by an electric motor and its construction is compact, so it is easy for operation and maintenance and increase the productivity.

Characteristics:

* This machine seal/close can lid/cover at can bottom/end at can body, and it has second seal, so it can seal tightly, and without leakage.

* This machine can seal perfect tin seam , and simple construction. It is light in weight ,small bulk, less noise.

* This machine can seal round cans in different sizes, It can seal different diameter when change some small parts.

* The machine can be adjusted according to the customer's specific requirements, if customers want to seal other size of cans, just need to change the sealing/seamer mould.

* This machine seal/close can lid/cover at can bottom/end at can body, and it has second seal, so it can seal tightly, and without leakage.

* This machine can seal perfect tin seam , and simple construction. It is light in weight ,small bulk, less noise.

* This machine can seal round cans in different sizes, It can seal different diameter when change some small parts.

* The machine can be adjusted according to the customer's specific requirements, if customers want to seal other size of cans, just need to change the sealing/seamer mould.

For the whole can filling line, there are some necessary machines you still need equip:

RO water treatment machine

Bottle blow molding machine

Bottle blow dryer

Bottle labeling machine

Code printer

Film shrink packing machine

company profile

ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. is located in Zhangjiagang city which is core of beverage machinery producer collection in China. Integrated the industry advantages and its own development in R&D, production, sales, after sales service,

BOTTLING MACHINERY is ready to serve more and more customers with our full range products and best service.BOTTLING MACHINERY is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

BOTTLING MACHINERY is ready to serve more and more customers with our full range products and best service.BOTTLING MACHINERY is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

We are the supplier who can design and manufacture for all kinds beverage production plant (pure drinking water, mineral water,carbonated drinks, juice, tea and beer, etc.)

Customer's service:

1. ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. can provide turn-key project for you, we can design the beverage factory plan according to your idea.

2. BOTTLING MACHINERY company have professional design team, our engineers can draw bottle samples and flow chart of workshop for you .

3. BOTTLING MACHINERY company can give you the best quotation for all kinds of beverage production, as long as you tell us which kind of drink you want to produce, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass bottle or can, etc.

After service:

1. We send our engineers to your factory to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the goods shipping to you:

a. Machines layout drawing.

b. Electricity diagram.

c. Machine certificate.

d. General manual book/maintenance book.

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.

1. ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. can provide turn-key project for you, we can design the beverage factory plan according to your idea.

2. BOTTLING MACHINERY company have professional design team, our engineers can draw bottle samples and flow chart of workshop for you .

3. BOTTLING MACHINERY company can give you the best quotation for all kinds of beverage production, as long as you tell us which kind of drink you want to produce, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass bottle or can, etc.

After service:

1. We send our engineers to your factory to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the goods shipping to you:

a. Machines layout drawing.

b. Electricity diagram.

c. Machine certificate.

d. General manual book/maintenance book.

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.

Packing&Delivery of BOTTLING

1. Our machines are packed by wooden case.

2. The delivery date of this machine is within 10-25 days after payment.

FAQ

Q:Are you a manufacturer or trade company?

A:We are a manufacturer in beverage bottling machine field more than 10 years, located at Leyu town, ZhangJiaGang, 2 hours from Shanghai, We will pick you up from Shanghai

Pudong Airport

to visit our factory.

Q:Do you have any certification?

A:SGS,ISO,CE etc

Q:What about the delivery time?

A:Usually 20-30 Working days for most kinds of machines

Q:What about the machine’s capacity?

A:1000 - 20000 bottles

per hour

based on 500ml bottle.

Q:The after-sale service

A:12 months warranty.

We can solve basic questions by telephone, email, whatsapp, wechat and video call.

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

Operating manuals will be sent with machines or by email.

We also have overseas service center

Q:If our bottle size changes, can we just do some adjustment on machine according to our new bottle?

A:Yes. Maybe you just need some spare little parts to change.

Q: If I want to purchase the machine, what information do I need to tell you?

A:a. What kind beverage you want to produce?

b. bottle volume? 250ml, 330ml, 500ml, 750ml, etc.?

c. Producing capacity requirement? How many bottles per hour?

d.Raw water analysis report .

e.Voltage and altitude.

Q:What kinds of product you supply?

A: Drink water/juice/carbonated drink filling line for bottle or can.

5 gallon/20L bottle water filling line.

Water treatment system.

Bottle blowing molding machine.

After packing system(label machine, PE film shrink packing machine, carton machine)

Sachet water packing line

Contact us

MS YOLANDA

5 years’ experience in foreign trade sales

Major in International business at

Yantai University

Whatsapp/Wechat: +8615190564896

Email:

yolanda@zjgbottlingmachinery.com

MR PHIL LANE

8 years’ experience in foreign trade sale

Major

Architecture, skilled CAD drawing, physical structure

China College English Test-6

Whatsapp/Wechat: +8615737466736

EMail: admin@zjgbottlingmachinery.com

EMail: admin@zjgbottlingmachinery.com

MR

ANDY

6 years in foreign trade sales

Major in mechanical engineering at university

Proficiency in photoshop drawing

Whatsapp/Wechat: +8613306249269

Email: sales1@zjgbottlingmachinery.com

Email: sales1@zjgbottlingmachinery.com

Hot Searches