- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ 3phase

-

Dimension(L*W*H):

-

16000*5000*20000mm

-

Weight:

-

3500 kg

-

Item name:

-

pet cat litter production line

-

Raw materials:

-

soybean, bentonite and so on

-

Color:

-

as your demand

-

Advantage:

-

Low Cost, high performance

-

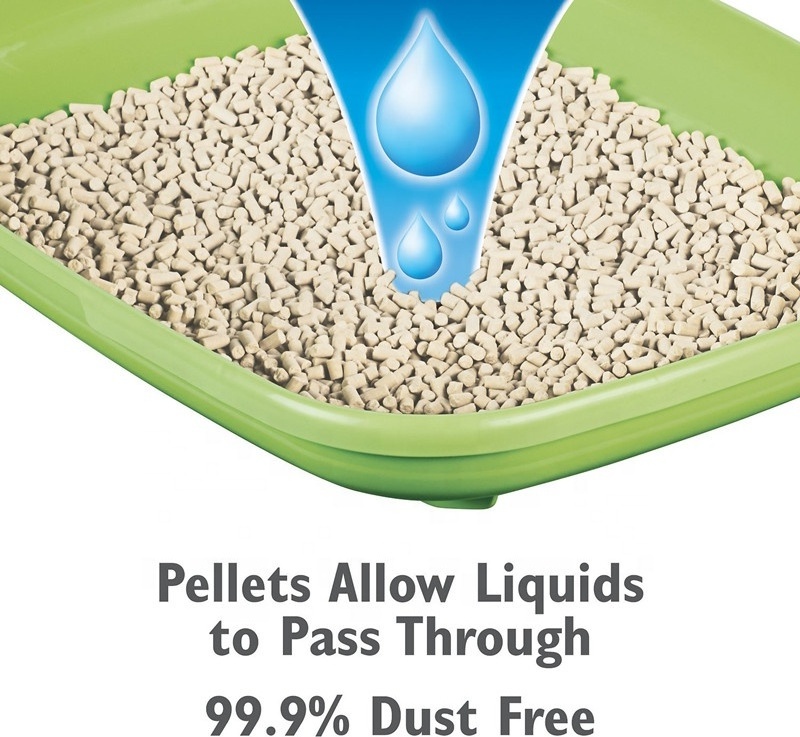

Pellet size:

-

2-5 mm

-

Feeding method:

-

manual or automatic by use bucket elevator or screw elevator

-

Processing Types:

-

cushing, mixing, pelleting,drying, cooling

-

Application Area:

-

cat pet application industry

-

Forming range:

-

99%

Quick Details

-

Max. Capacity:

-

200-500kg/H

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Double Crane

-

Voltage:

-

380V 50HZ 3phase

-

Dimension(L*W*H):

-

16000*5000*20000mm

-

Weight:

-

3500 kg

-

Item name:

-

pet cat litter production line

-

Raw materials:

-

soybean, bentonite and so on

-

Color:

-

as your demand

-

Advantage:

-

Low Cost, high performance

-

Pellet size:

-

2-5 mm

-

Feeding method:

-

manual or automatic by use bucket elevator or screw elevator

-

Processing Types:

-

cushing, mixing, pelleting,drying, cooling

-

Application Area:

-

cat pet application industry

-

Forming range:

-

99%

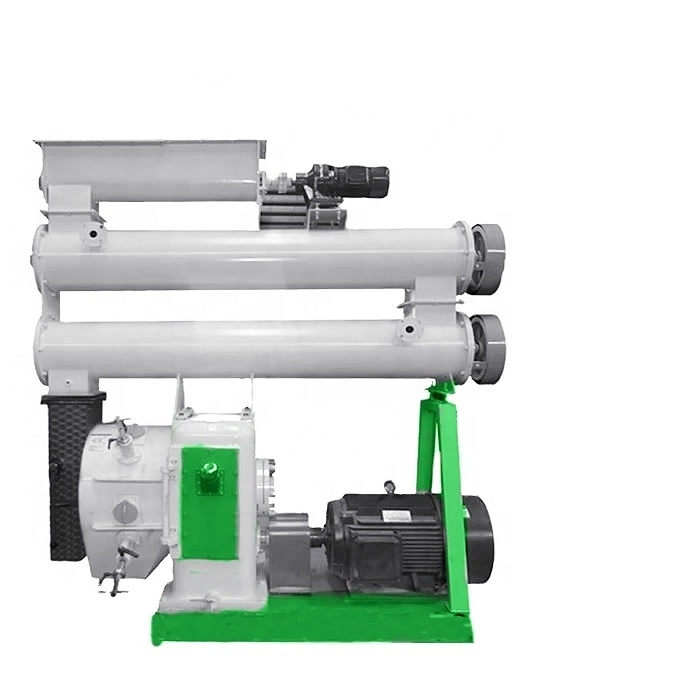

Breeding Plant Feed Pellet Machine to Make Cat Litter Pellet Machine Production Line Rice Bran Straw Pellet Machine

Nontoxic tofu cat litter pellets production line machinery is a complete set of machines that are specifically used to make cat litter pellets. The capacity of feed pellet line produced by Shandong Double Crane Machinery Manufacture Co.,Ltd. can range from 1t per hour to 3t per hour. The machine group generally including the following process: raw materials receiving and cleaning process, crushing process, mixing process, pellet making process, pellet cooling process, (pellet crumbling process), sifting process and packaging process.

Features and Advantages

1).Driven by variable frequency motor, the feeder can be adjusted automatically within a certain scope according to the production;

2).The interlock device, outer machine discharging device and over-load protection device work together to ensure the safety and reliability;

3).Magnetic separation and removal mechanisms are configured to prevent the iron impurities from entering into the suppression of granulation chamber.

4).The cooking time and result are highly improved by the extended stainless steel feeding conditioner with the axial inlet steam.

5).The Circulating lubrication oil system is specially designed to ensure the bearings in good condition.

6).The ordinary conditioner, thermal insulation conditioner or double-shaft differential conditioner are options according to your requirements.

Raw materials

The bean pulp,grain, corn powder,crushed straw and grass,the meat and bone meal,fish meal, Miscellaneous meal. Also can be used to process rice husk, cottonseed skins,weeds,crop stalks, sawdust, and other plant wastes, especilly low-bonging and unformed materials.

Range of application

The poultry feed pellet production line is used to Make the pellet for poultry/animal feed, such as the cow/cattle, the pigeon ,the rabbit , the chicken ,the fish , the dog, the pig ,the horse,the sheep ,the shrimp and other animal,etc.

Pellet size

1.For pig, the pellet diameter is usually ø3.5-6.5mm;

2.For cattle, the pellet diameter is usually ø4.5-8mm;

3.For chicken, pellet diameter is usually ø3.2mm;

4.For fish, pellet diameter is usuallyø2.0, ø2.5, ø3.0mm;

5.For shrimps, pellet diameter is usually ø1.0-ø3.5mm.

Technical Parameters of key machine-feed pellet mill

Technical Parameters

|

model |

HKJ250 |

SZLH320 |

SZLH350 |

SZLH420 |

SZLH508 |

|

Capacity(t/h) |

1-2 |

1-4 |

2-6 |

3-12 |

4-20 |

|

Main power(kw) |

22 |

37 |

55 |

110 |

132 |

|

Conditioner power(kw) |

2.2 carbon steel |

2.2 SS (stainless steel) |

2.2 SS |

2.2 SS |

5.5 SS |

|

Feeder power(kw) |

0.75 |

0.75 |

0.75 |

1.5 |

1.5 |

|

Note |

Belt driven |

Gear driven |

Gear driven |

Gear driven |

Gear driven |

Production Flow

The detailed process of Feed Mill Plant:

Step 1.Raw materials receiving and cleaning process-(drum sieving precleaner, conical powder sieve and peermanent magnetic drum).Drum sieving precleaner is used to clean and sort out the big debris such as corn stalk, stones, rope head, branches, corn cobs and the small debris such as mud, sand and blighted grain. When the raw materials are powder, conical powder sieve is used to clean the debris in the powder. (And the machine can also be used after the mixing process and before the pellet making process to make sure the pellet mill can be smooth operation).

Step 2. Crushing process---hammer mills We have many kinds of hammer mills for your choice: water drop hammer mill, multifunctional hammer mill and 9fq hammer mill etc. This process is mainly used to crush to raw materials into powder.

Step 3.Mixing process---feed mixer The feed mixer we have are single shaft double screw mixer, double shaft paddle mixer, vertical mixer. The process is used to mixed the crushed materials with higher unifomity.

Step 4.

Pellet making process---feed pellet mill We have five models of feed pellet mill for your choice. This process is to press the pellets out.

Step 5.Pellet cooling process---counterflow cooler The newly pressed pellets are very high in temperature. This process is to cool the pellets to ±3-5℃ of the room temperature.

Step 6.Pellet crumbling process----feed crumbler(roller crusher) This process is mainly to crush the big pellets into small ones. It is mainly used for chicken feed pellet line.

Step 7.Sifting process--vibratory sizing sieve and plenary rotary sizing sieve This process is mainly to sort out the inappropriate pellets and powder and send the standard pellets to next process.

Step 8. Packing process -----packaging machine This process is to pack the pellets into bags which is conveninet for storage and transportation.

Products Certification

Large capacity palm kernel shell pellet mill in hot sale inner packed by stretch film, outer packed by venner case. This will keed the machines in good condition when shipping.