- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

203-492-7

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KLB

-

Model Number:

-

CL-26AB-31

-

Type:

-

Neutral

-

A and B with ratio:

-

1:1

-

Viscosity:

-

<100000mpa.s

-

Appearance:

-

thick liquid

-

Features:

-

Good adhesion

-

Curing condition:

-

TC10: 19S*150℃

-

Storage:

-

20℃-25℃

-

Proportion:

-

1.28

-

Shelf life:

-

6 Months

-

Application:

-

3C electronic products

-

Package:

-

1KG/Bottle or 3KG/Bottle

Quick Details

-

CAS No.:

-

63148-62-9

-

Other Names:

-

silicone adhesive

-

MF:

-

C6H18OSi2

-

EINECS No.:

-

203-492-7

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KLB

-

Model Number:

-

CL-26AB-31

-

Type:

-

Neutral

-

A and B with ratio:

-

1:1

-

Viscosity:

-

<100000mpa.s

-

Appearance:

-

thick liquid

-

Features:

-

Good adhesion

-

Curing condition:

-

TC10: 19S*150℃

-

Storage:

-

20℃-25℃

-

Proportion:

-

1.28

-

Shelf life:

-

6 Months

-

Application:

-

3C electronic products

-

Package:

-

1KG/Bottle or 3KG/Bottle

Product Description

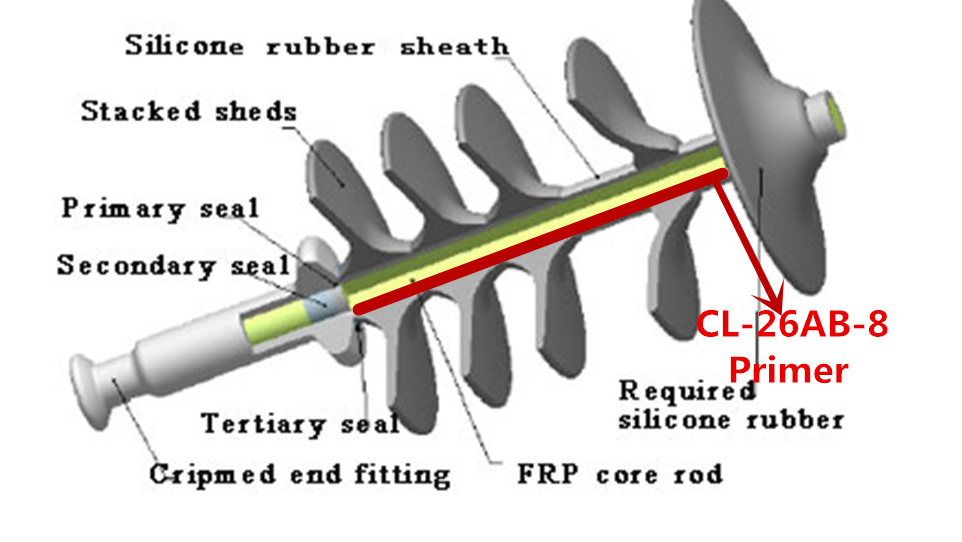

High Performance Heated Silicone Primer for HTV silicon bonding aluminum compression molding

Application

Specification

|

Name

|

Silicone Adhesives CL-26AB-31

|

|

Operate temperature

|

110°C~130°C

|

|

Appearance

|

Transparent or Pasty

|

|

Specifical gravity

|

0.95 g/cm3

|

|

Features

|

Component solvent

|

|

Solvent

|

Apply to soft silicone rubber,PA,metal,bakelite and so on.

|

Operating Steps

Processing

1, Surface Treatment: The surface should be cleaned or degreased by chemical cleaning agent.

2, Coating Method: Firstly, Thoroughly mixed A and B, and then painting, dipping, spraying or printing.

3, Drying condition: Baking at 110°C~130°C for 15~20 minutes.

4, Temporary Storage:All the products which coated should be use within 24 hours, when storage ,it should be placed away from pollution and high temperature or wet air, they can be stored within 3 days.

5, Bonding Method: Silicone raw material gluing with other material should be molded at high temperature or hot air vulcanization

2, Coating Method: Firstly, Thoroughly mixed A and B, and then painting, dipping, spraying or printing.

3, Drying condition: Baking at 110°C~130°C for 15~20 minutes.

4, Temporary Storage:All the products which coated should be use within 24 hours, when storage ,it should be placed away from pollution and high temperature or wet air, they can be stored within 3 days.

5, Bonding Method: Silicone raw material gluing with other material should be molded at high temperature or hot air vulcanization

Attention

1, Keep the product in dry and shade place and avoid heat and fire.

2, Please cap its cover after use to avoid volatilization. (store the used primer in separate way to lengthen the storage time )

3, The solvent is harmful, the workplace should be ventilated and fireproof and avoid long term inhalation and skin contact.

4, The compatibility test is required for the silicone primer with substrates in mold curing process as the primer will result in bad cure when contacting with organic compounds like N, P, S, Sn, Pb, Hg, Sb, Bi as ionic compound.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches