Depalletizer can be designed as Fully Automatic or Semi Automatic, it is for the unloading the three piece Can, two piece Alu

Can,and Glass Bottle from Pallet to Production Line. The electrical parts like PLC, photoelectric switch, position switch,

pneumatic controller adopt the electrical products from famous brands in German, Japan, and Taiwan.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±5mm

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINMAO, can filling and seaming machine

-

Dimension(L*W*H):

-

1930*1640*3200

-

Weight:

-

2000 KG

-

Keywords:

-

can filling and seaming machine

-

processing:

-

energy drink filling machines

-

material:

-

SUS304

-

bottle type:

-

tin can

-

process type:

-

full automatic

-

process method:

-

filling,capping

-

other:

-

can filling and seaming machine

-

Processing Types:

-

Automatic Filling Sealing Production Line

-

Usage:

-

Beverage Packaging

-

Product name:

-

Soda Water can filling machine production line

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Beer, Other

-

Filling Accuracy:

-

±5mm

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINMAO, can filling and seaming machine

-

Dimension(L*W*H):

-

1930*1640*3200

-

Weight:

-

2000 KG

-

Keywords:

-

can filling and seaming machine

-

processing:

-

energy drink filling machines

-

material:

-

SUS304

-

bottle type:

-

tin can

-

process type:

-

full automatic

-

process method:

-

filling,capping

-

other:

-

can filling and seaming machine

-

Processing Types:

-

Automatic Filling Sealing Production Line

-

Usage:

-

Beverage Packaging

-

Product name:

-

Soda Water can filling machine production line

Product Application

Beverage / Juice Can

Wine / Beer Can

Ketchup / Sauce Can

Tin

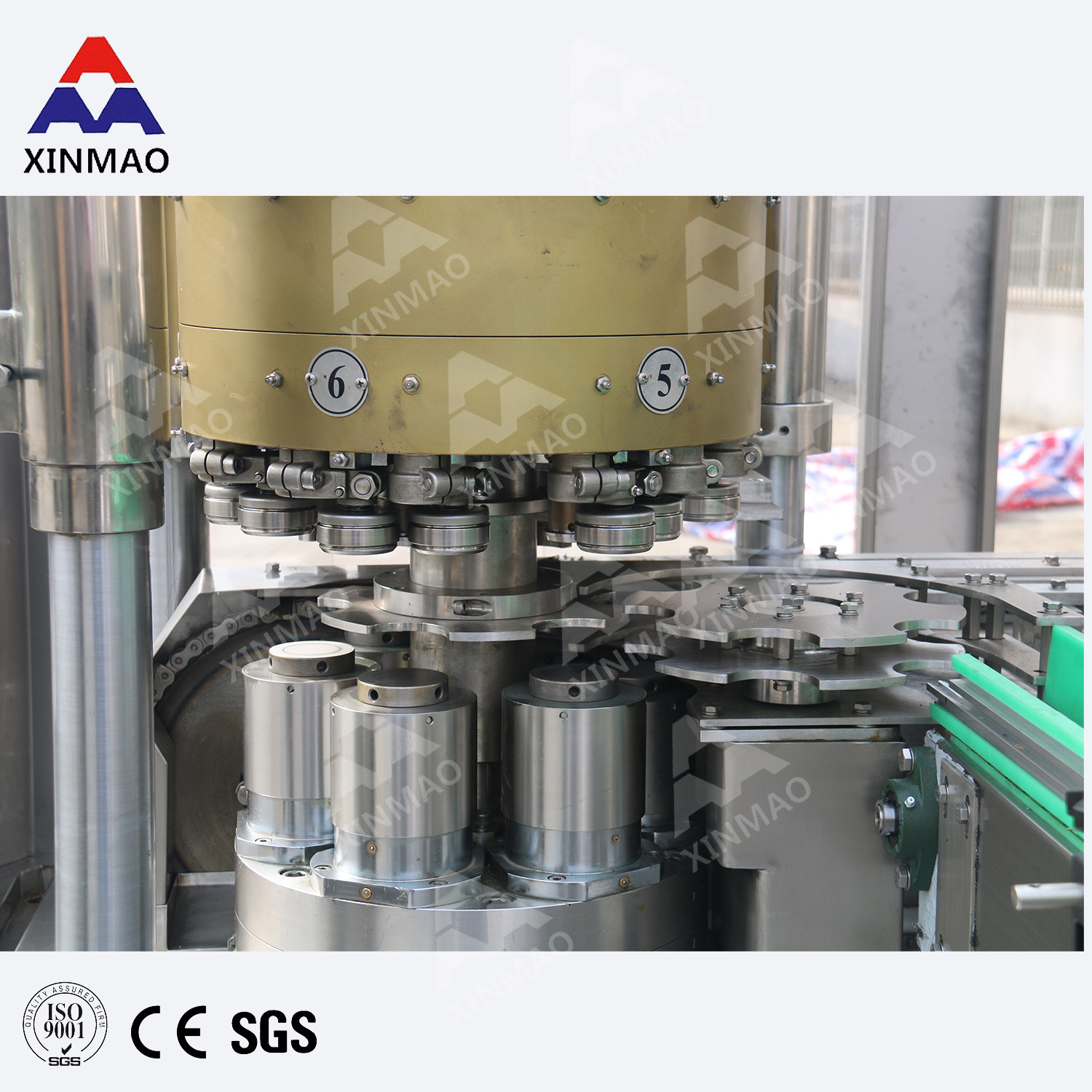

Can Soda Beverage Production Line Canned Drink Automatic Monoblock 2 In 1 Filling And Sealing Machines

The machine is suitable for filling and sealing beverage or brewage industry ,it have such features as rapid filling and sealing speed ,consistent height from the liquid level in the can to the can mouth after filling ,stable machine operation ,good sealing quality ,beautiful and decent appearance ,convenient use and maintenance ,touch screen operation ,frequency conversion speed adjustment ,etc.it is the most ideal filling and sealing device for beverage plants and brew houses.

|

Aluminum Can Carbonated Drink Isobaric Filling Machine Monoblock 2 in 1

|

|

|

||

|

Model

|

Speed/Cph

|

Usage

|

||

|

DGF12-1

|

1500

|

Can Type: Aluminum Can, Plastic Can

|

||

|

DGF12-4

|

6000

|

Can Size: 150ml~750ml

|

||

|

DGF18-4

|

9000

|

Lid Type: 201, 202

|

||

|

DGF24-6

|

12000

|

Liquid Type: carbonated soft drink, cola, sparkling wine, CSD, carbonated juice, sparkling water

|

||

|

DGF32-6

|

15000

|

|

||

Related Products

EMPTY CAN DEPALLETIZER

VACUUM DETECTOR

Because the different Container internal vacuity will cause the different appearance of sealed lid, this detector adopts high precision optical component to identify the tiny size or shape difference that compare with reference parameters. After the data been processed by the central processing unit, the detector will immediately spot out the unqualified Container, and the unqualified Container will be rejected by the following cylinder pusher from the production line. This detector can be applied on all the two pieces Alu Can, three pieces TP Can, Lug Cap Jar, and other Containers that with cover lids, the key components are all from German and Japan, with easy and high efficiency operation, this detector had been widely used in many Beverage and Canned Food factories.

Can INTERNAL PRESSURE DETECTOR

This detector detects the real time internal pressure of Can or PET Bottle , after liquid nitrogen or soft drink been filled. Once there is one unqualified Can been detected, the detector will fast react by firstly reject the Can, then alarm the operator with Sound and Light. It also can process the real time monitoring, if there were batch unqualified Cans been detected, it would issue warning signal to notice the operator, further more it also can be programmed to control the up stream production, by stopping the running of production line, to prevent further more unqualified accidents.

Automatic PVC Shrink Labeling Machine

Application: PVC / PET / OPS label sleeve

* Stainless steel Main Machine Frame / Famous electrical components

* Stainless steel Main Machine Frame / Famous electrical components

Automatic PE Film Shrink Wrapping Machine

This machine is suitable for wrapping and packaging of such products as pop-top, mineral water, bottles beer, drinks etc without

bottom-tray(or with bottom-tray). Working with PE shrink tunnel to pack the goods perfectly. The whole producing of shrink

wrapping machine process adopt the Germany advanced technology. And the main parts of shrink wrapping machine are imported from

international famous companies, capability stable and using long-time.

bottom-tray(or with bottom-tray). Working with PE shrink tunnel to pack the goods perfectly. The whole producing of shrink

wrapping machine process adopt the Germany advanced technology. And the main parts of shrink wrapping machine are imported from

international famous companies, capability stable and using long-time.

Customer Plant Layout

Real Picture Of Customer Factory

Hot Searches