1. Design & Engineering During Quotation

2. Sample Chain (links) Availability Upon Request

3. Daily & Weekly Reporting During Order Execution

4. Final Data Book Including Full Reports & Certificates With Order Delivery

5. 24x7 Service Hotline Upon Clients Questions And Complaints

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SCIC

-

Model Number:

-

G80 6.3X19mm

-

Material:

-

Alloy Steel

-

KeyWords:

-

Lifting and lashing, chain, short link chain, round link chain lifting

-

Surface Treatment:

-

black finished,black painted,galvanized

-

Application:

-

Lifting

-

Standard:

-

EN 818-2

-

Diameter:

-

6.3mm

-

Certificate:

-

ISO9001

-

Sample:

-

sample chain / link available

-

Grade:

-

Grade80

-

Name:

-

Manufactured From High Strength G80 20mn2 Steel Load Chain Link Chain

Quick Details

-

Finish:

-

Black, ZINC, Plain

-

Structure:

-

Welded Chain

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SCIC

-

Model Number:

-

G80 6.3X19mm

-

Material:

-

Alloy Steel

-

KeyWords:

-

Lifting and lashing, chain, short link chain, round link chain lifting

-

Surface Treatment:

-

black finished,black painted,galvanized

-

Application:

-

Lifting

-

Standard:

-

EN 818-2

-

Diameter:

-

6.3mm

-

Certificate:

-

ISO9001

-

Sample:

-

sample chain / link available

-

Grade:

-

Grade80

-

Name:

-

Manufactured From High Strength G80 20mn2 Steel Load Chain Link Chain

Round steel link chain

Black Alloy G80 Hot Dip Galvanized Lifting Chain High Tensile Heavy Duty Link Chain

Products Description

Category:

lifting and lashing, chain, short link chain, round link chain lifting, Grade 80 chain, G80 chain, chain sling, sling chains, DIN 818-2 medium tolerance chain for chain slings Grade 8, alloy steel chain

Application:

lifting and lashing, loads lifting, loads binding

SCIC Grade 80 (G80) chains for lifting are made as per EN 818-2 standards, with nickel chromium molybdenum manganese alloy steel per DIN 17115 standards; well designed / monitored welding & heat-treatment ensure chains mechanical properties including test force, breaking force, elongation & hardness.

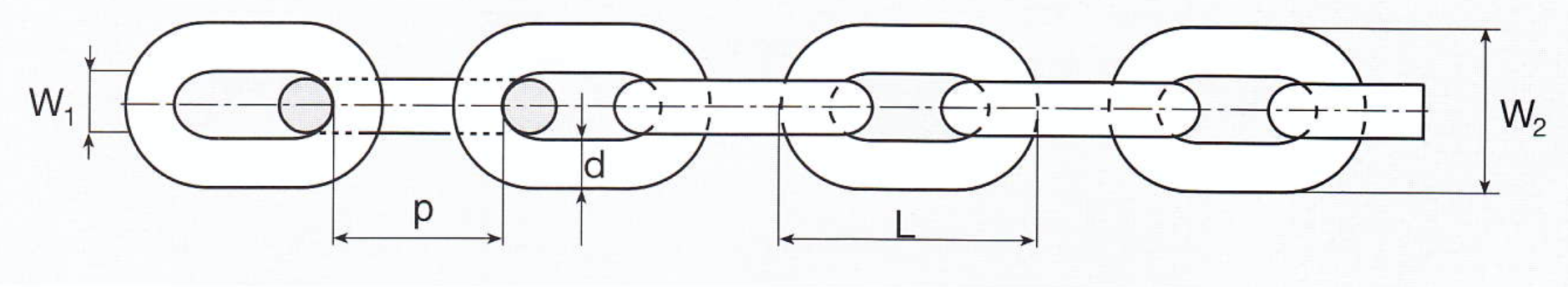

Figure 1:

Grade 80 chain link dimensions

Table 1:

Grade 80 (G80) chain dimensions, EN 818-2

|

diameter

|

|

pitch

|

|

width

|

|

unit weight

(kg/m)

|

|||

|

nominal

d (mm)

|

tolerance

(mm)

|

p (mm)

|

tolerance

(mm)

|

inner W1

min. (mm)

|

outer W2

max. (mm)

|

|

|||

|

6

|

± 0.24

|

18

|

± 0.5

|

7.8

|

22.2

|

0.8

|

|||

|

7

|

± 0.28

|

21

|

± 0.6

|

9.1

|

25.9

|

1.1

|

|||

|

8

|

± 0.32

|

24

|

± 0.7

|

10.4

|

29.6

|

1.4

|

|||

|

10

|

± 0.4

|

30

|

± 0.9

|

13

|

37

|

2.2

|

|||

|

13

|

± 0.52

|

39

|

± 1.2

|

16.9

|

48.1

|

4.1

|

|||

|

16

|

± 0.64

|

48

|

± 1.4

|

20.8

|

59.2

|

6.2

|

|||

|

18

|

± 0.9

|

54

|

± 1.6

|

23.4

|

66.6

|

8

|

|||

|

19

|

± 1

|

57

|

± 1.7

|

24.7

|

70.3

|

9

|

|||

|

20

|

± 1

|

60

|

± 1.8

|

26

|

74

|

9.9

|

|||

|

22

|

± 1.1

|

66

|

± 2.0

|

28.6

|

81.4

|

12

|

|||

|

23

|

± 1.2

|

69

|

± 2.1

|

29.9

|

85.1

|

13.1

|

|||

|

24

|

± 1.2

|

72

|

± 2.1

|

30

|

84

|

14.5

|

|||

|

25

|

± 1.3

|

75

|

± 2.2

|

32.5

|

92.5

|

15.6

|

|||

|

26

|

± 1.3

|

78

|

± 2.3

|

33.8

|

96.2

|

16.8

|

|||

|

28

|

± 1.4

|

84

|

± 2.5

|

36.4

|

104

|

19.5

|

|||

|

30

|

± 1.5

|

90

|

± 2.7

|

37.5

|

105

|

22.1

|

|||

|

32

|

± 1.6

|

96

|

± 2.9

|

41.6

|

118

|

25.4

|

|||

|

36

|

± 1.8

|

108

|

± 3.2

|

46.8

|

133

|

32.1

|

|||

|

38

|

± 1.9

|

114

|

± 3.4

|

49.4

|

140.6

|

35.8

|

|||

|

40

|

± 2

|

120

|

± 4.0

|

52

|

148

|

39.7

|

|||

|

45

|

± 2.3

|

135

|

± 4.0

|

58.5

|

167

|

52.2

|

|||

|

48

|

± 2.4

|

144

|

± 4.3

|

62.4

|

177.6

|

57.2

|

|||

|

50

|

± 2.6

|

150

|

± 4.5

|

65

|

185

|

62

|

|||

Table 2:

Grade 80 (G80) chain mechanical properties, EN 818-2

|

diameter

d (mm)

|

working load limit

WLL (t)

|

manufacturing proof force

MPF (kN)

|

min. breaking force

BF (kN)

|

|||

|

6

|

1.12

|

28.3

|

45.2

|

|||

|

7

|

1.5

|

38.5

|

61.6

|

|||

|

8

|

2

|

50.3

|

80.4

|

|||

|

10

|

3.15

|

78.5

|

126

|

|||

|

13

|

5.3

|

133

|

212

|

|||

|

16

|

8

|

201

|

322

|

|||

|

18

|

10

|

254

|

407

|

|||

|

19

|

11.2

|

284

|

454

|

|||

|

20

|

12.5

|

314

|

503

|

|||

|

22

|

15

|

380

|

608

|

|||

|

23

|

16

|

415

|

665

|

|||

|

24

|

18

|

452

|

723

|

|||

|

25

|

20

|

491

|

785

|

|||

|

26

|

21.2

|

531

|

850

|

|||

|

28

|

25

|

616

|

985

|

|||

|

30

|

28

|

706

|

1130

|

|||

|

32

|

31.5

|

804

|

1290

|

|||

|

36

|

40

|

1020

|

1630

|

|||

|

38

|

45

|

1130

|

1810

|

|||

|

40

|

50

|

1260

|

2010

|

|||

|

45

|

63

|

1590

|

2540

|

|||

|

48

|

72

|

1800

|

2890

|

|||

|

50

|

78.5

|

1963

|

3140

|

|||

|

notes: total ultimate elongation at breaking force is min. 20%;

WLL shall not exceed 25% of breaking force. |

|

|

|

|||

|

changes of Working Load Limit in relation to temperature

|

|

|

|

Temperature (°C)

|

WLL %

|

|

|

-40 to 200

|

100%

|

|

|

200 to 300

|

90%

|

|

|

300 to 400

|

75%

|

|

|

over 400

|

unacceptable

|

|

Recommend Products

About Us

About Us -

SCIC Round Link Chain

As a round steel link chain manufacturer for 30 years, our factory has been staying with and serving the very important period of Chinese chain making industry evolution catering for mining (coal mine in particular), heavy lifting, and industrial conveying requirements on high strength round steel link chains. We don’t stop at being the leading round link chain manufacturer in China (with annual supply over 10,000T), but stick to non-stopping creation and innovation.

Raw material stock

Round steel link chain making machines

Heat-treatment furnaces

Force / load testing machines

Laboratory facilities

Coating and packing

Why Choose Us

Our advantage

Product Packaging

FAQ

Q1: Is SCIC a manufacturer?

Yes, SCIC is a round link chain manufacturer for over 30 years for serving Chinese market as well as overseas markets on mining and industrial lifting & rigging applications. We set up SCIC now to enhance international marketing to offer clients worldwide with better service and professionality.

Q2: What scope of products do SCIC produce and supply?

We specialize in making round link chains of high grade and strength for coal mining industry Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), road header machines, as well as flat link chains; we make Grade 70, Grade 80 and Grade 100 chains for lifting and rigging (chain slings), bucket elevators and fishing industry.

Q3: Do you maintain full inhouse testing and inspection facilities and measures?

Yes, we carry out inhouse tests including manufacturing force test, breaking force test, charpy V notch impact test, bending test, tensile test, hardness test, non destructive examination (NDE), macro examination and micro examination, finite element analysis, etc., in accordance with DIN 22252, DIN EN 818 standards and client’s requirements.

Q4: Do you make ODM and OEM?

Yes, with our automatic and robotized machines and experienced engineers, we can make ODM and OEM round link chains to clients’ specifications

Q5: Do you have minimum order quantity (MOQ)?

For client of first time ordering, there is no MOQ requirement, and we’re glad to supply flexible quantity for client’s trial use.

Q6: What is your chain finishing / coating?

We offer different color coatings per clients requirements, as well as galvanization and other means of finishing per order negotiation.

Q7: What’s your chain packaging means?

We offer various packaging means, including jumbo bags, drums, pallets, steel frames, etc.

Q8: What’s your quality assurance and guarantee?

We issue full test reports and photos for client’s review during manufacture and before delivery to confirm release on delivery. In case of any failure during our round link chain service, we will be positively cooperate with client on failure analysis (including retest) to determine the causes and proper resolutions to mutual understanding and acceptance.

Hot Searches