- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

150bag/min

-

Weight (KG):

-

1850

-

Voltage:

-

220v/380v

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JINTAI

-

Product name:

-

Disposable Plastic Cutlery Packing Machine

-

Machine type:

-

Full-automatic

-

Suitable for:

-

Restaurant

-

Packing material:

-

OPP

-

Packing type:

-

POF PE Film Wrapping

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, COATING, Sealing, BOXING, counting

-

Packaging Type:

-

Cartons, CANS, Bags, Film, Foil, Belt, case

-

Packaging Material:

-

Plastic, Paper, Wood

-

Production Capacity:

-

150bag/min

-

Weight (KG):

-

1850

-

Voltage:

-

220v/380v

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JINTAI

-

Product name:

-

Disposable Plastic Cutlery Packing Machine

-

Machine type:

-

Full-automatic

-

Suitable for:

-

Restaurant

-

Packing material:

-

OPP

-

Packing type:

-

POF PE Film Wrapping

Product Overview

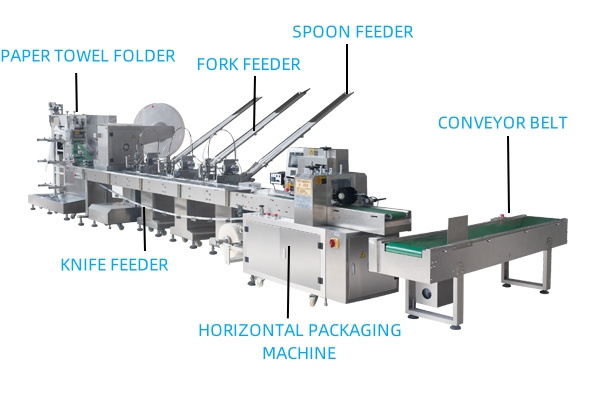

High speed new tableware napkin spoon fork knife straw disposable airline plastic cutlery auto packing line could be packed disposable / plastic napkin(paper tissue), spoon, fork, knife, salt/pepper, sugar, straw, toothpick, chopsticks, stirrer, wet wipe..... specialized for airline, hotel, restaurant, fast food....

PRODUCT SPECIFICATIONS

|

Product Name

|

Automatic Disposable Cutlery (Napkin/ Spoon/Fork/Knife/Toothpick) Packing Machine

|

|

Model

|

RZB260-A

|

|

Packing Material

|

OPP Film, Aluminum Laminated Film, Pure Aluminum Film, and other composite films

|

|

Packing Speed

|

20-150bags/min

|

|

Paper Towel Size

|

6-17inch

|

|

Fold Width

|

25-60mm

|

|

Max Diameter Of Paper Roll

|

900mm

|

|

Max Width Of Paper Roll

|

450mm

|

|

Max Film Width

|

260mm

|

|

Packing Film Thickness

|

0.012-0.05mm

|

|

Voltage

|

220v/380v

|

|

Total Power

|

10KW

|

|

Total Weight

|

2600kg

|

|

Overall Dimension

|

7500x1400x1600mm

|

Main Features

1) Three servo motors' drive mode:

1.1 Positioning stop function, save packaging materials;

1.2 Protect the cutter, improve efficiency.

2) Innovative file hanging structure design to ensure the same tension when using packaging films of different diameters and

materials to ensure the smooth operation of the machine;

3) High sensitivity photoelectric color label tracking, sealing and cutting position is more accurate, saving time and film;

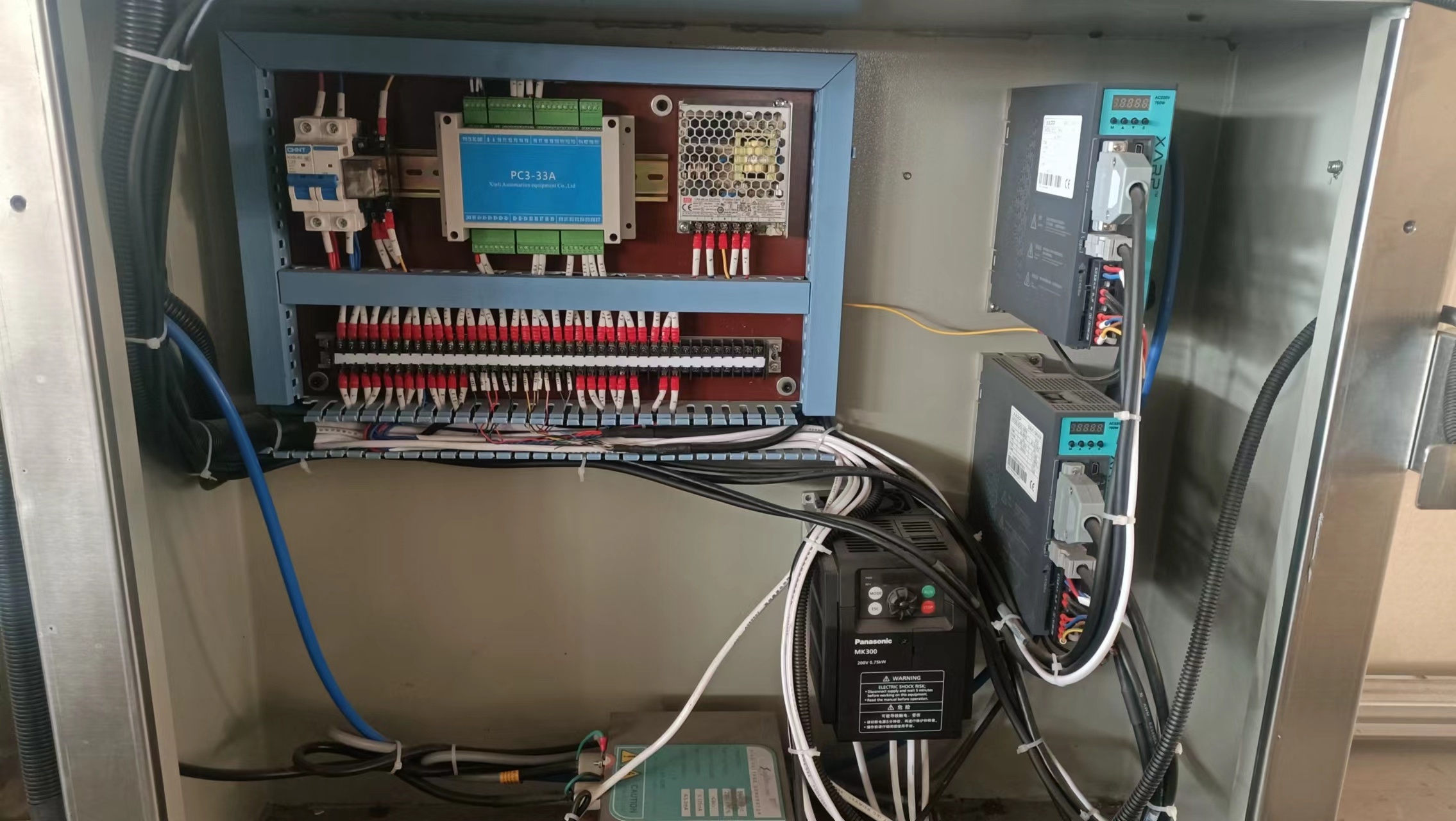

4) Imported electrical appliances and touch screen, free setting of parameters, convenient and fast;

5) All operations are controlled by software, simple and easy to set&use, convenient for technical upgrade and function adjustment in the future;

6) Temperature independent PID control, better suitable for all kinds of packing material;

7) Compact structure design, simple rotation system, stable performance, more convenient maintenance;

8) With fault self-diagnosis function, reduce maintenance time, to ensure stable production.

1.1 Positioning stop function, save packaging materials;

1.2 Protect the cutter, improve efficiency.

2) Innovative file hanging structure design to ensure the same tension when using packaging films of different diameters and

materials to ensure the smooth operation of the machine;

3) High sensitivity photoelectric color label tracking, sealing and cutting position is more accurate, saving time and film;

4) Imported electrical appliances and touch screen, free setting of parameters, convenient and fast;

5) All operations are controlled by software, simple and easy to set&use, convenient for technical upgrade and function adjustment in the future;

6) Temperature independent PID control, better suitable for all kinds of packing material;

7) Compact structure design, simple rotation system, stable performance, more convenient maintenance;

8) With fault self-diagnosis function, reduce maintenance time, to ensure stable production.

Product Description

Touch Screen

lt adopts PLC controller and touchscreen (man -machine interface)all the working parameters can besetup on the control panel which

is convenient for parameter settingand adjusting.(Makes the packing machine easier to operate)

is convenient for parameter settingand adjusting.(Makes the packing machine easier to operate)

Electric system

With CHINT and other high-quality brand electrical components, stable and better quality

Raw material stand

Raw paper roll can be put on this stand and paper unwinding by transmission belt

Napkin Former

Napkin Roll Cutting into Paper Sheet

Automatic Cutlery Feeder

Automatic Feeding Plastic /Paper/Plastic Fork Spoon Knife

Packaging Forming

Double frequency conversion control,

the bag length is cut immediately, no need to adjust, and it can be done in one step

SIMILAR PRODUCTS

Hot Searches