- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

36*6*3M

-

Weight (KG):

-

18000 KG

-

Warranty:

-

12 MONTH

-

Name:

-

full-auotmatic ps foam container making machine

-

Application:

-

Plates, food container/tray/bowl

-

Working speed:

-

3-5s/mould

-

Controller:

-

PLC Screen

-

Key word:

-

take away container production line

-

Forming area:

-

1000*1250mm

-

Forming pressure:

-

35T

-

Certification:

-

CE/ISO, CE

-

Weight:

-

18T

-

Power:

-

170KW

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HONGRUN

-

Machine Type:

-

Automatic

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

36*6*3M

-

Weight (KG):

-

18000 KG

-

Warranty:

-

12 MONTH

-

Name:

-

full-auotmatic ps foam container making machine

-

Application:

-

Plates, food container/tray/bowl

-

Working speed:

-

3-5s/mould

-

Controller:

-

PLC Screen

-

Key word:

-

take away container production line

-

Forming area:

-

1000*1250mm

-

Forming pressure:

-

35T

-

Certification:

-

CE/ISO, CE

-

Weight:

-

18T

-

Power:

-

170KW

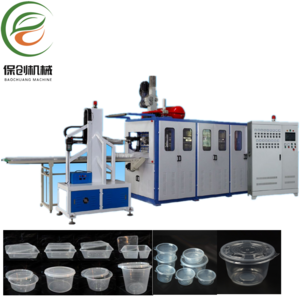

disposable take away food container foam thermocol plate box making machine

Click here for free samples or unexpected surprise.

disposable take away food container foam thermocol plate box making machine production line

disposable foam machine for food box high output lunch food container machine includes

3 PARTS

:

(1)

PS foam sheet extrusion line

: make PS foam sheet from raw material

| Model | HR-PSP70/90 | HR-PSP105/120 | HR-PSP120/150 | HR-PSP135/150 | HR-PSP150/200 |

| Screw Diameter | Φ70/90 | Φ105/120 | Φ120/150 | Φ135/150 | Φ150/200 |

| Foam Rate | 1.0-3.0 | 1.0-3.0 | 1.0-3.0 | 1.0-3.0 | 1.0-3.0 |

| Width of Product (mm) | 640-1080 | 640-1080 | 640-1080 | 640-1200 | 1000-1350 |

| Thickness of Product (mm) | 1.0-3.0 | 1.0-3.5 | 2.0-3.5 | 2.0-5.0 | 2.0-5.0 |

| Output (kg/h) | 60-90 | 100-180 | 180-250 | 250-320 | 400-600 |

| Cutting Mode | Single Cutting | Double Cutting | |||

| Cooling Mode | Cooling by Wind and Water | ||||

| Mounted Power(kw) | 120 | 150 | 180 | 260 | 380 |

| Overall Size(m) | 22*4.0*2.8 | 24*4.1*2.8 | 26*4.2*3 | 28*4.2*3.2 | 30*5.2*3.2 |

| Total Weight (T) | 10 | 12 | 15 | 18 | 23 |

(2)

Automatic Vacuum Forming and Cutting Integrated Machine

: make PS sheet to finished products, such as PS foam tray, PS foam box etc. (we can design mold according to customer requirements)

| Model | Unit | HR-FCA750 | HR-FCA1100 | HR-FCA1250 | HR-FCA1400 |

| Max. forming area | mm | 750*1000 | 1000×1100 | 1000*1250 | 1000*1400 |

| Max. forming depth | mm | 80 | 80 | 80 | 80 |

| Production efficiency | s/die | 3~5 | 3~5 | 3~5 | 3~5 |

| Forming pressure | T | 12 | 15 | 18 | 20 |

| Mounted power | kw | 140 | 170 | 200 | 250 |

| Total weight | T | 14 | 16 | 18 | 20 |

| Installation size | m | 12*1.8*3.2 | 13×2×3.2 | 15*2.3*3.5 | 18*2.5*3.5 |

(3)

PS Crushing and Recycling Machine:

recycle waste products to granules, the can mix with new material and put into PS foam sheet extruder again.

| Model | HR-180+120/100 | |

| Screw diameter(mm) | Φ180+120/Φ100 | |

| Production efficiency (kg/h) | 80-130 | |

| Crusher motor power (kw) | 15 | |

| Main motor power (kw) | 29.5 | |

| Heating power (kw) | 35 | |

| Pressing material motor power(kw) | 1.5 | |

| Granulator (kw) | 2.2 | |

| Power supply | Three-phase 380v/50HZ | |

| Dimension size(mm) | 13000*3400*3000 | |

| Total weight (mt) | 3 | |

Features for disposable foam machine for food box high output lunch food container machine

1. Suck and pull the food containers up. Even the containers don’t be sucked out successfully, this won’t affect next move.

2. There are one conveyor belt on each side, both can achieve automatically stacking, reduce labor intensity.

3. Heater box separate into three parts, hydraulic cutting speed is faster, and use mechanical arms to suck products, all above methods reduce the whole working time.

4. Extend mold length, making the forming mold area larger and improving the production efficiency.

https://youtu.be/mlKoUKff9ok

https://www.youtube.com/watch?v=86sXuz08_3c