- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1200 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V ,Customized

-

Power:

-

12 Kw, 67800w

-

product Name:

-

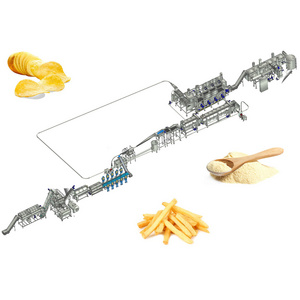

French Fries Production Line Semi Automated French Fries Machine

-

Capacity:

-

70KG/H

-

Material:

-

304 Stainless Steel

-

Application:

-

French Fries

-

Heating Source:

-

Electric

-

Applicable Industries:

-

Food & Beverage Factory

-

After Warranty Service:

-

Video technical support

Quick Details

-

Machinery Capacity:

-

100-500 Kg/hour

-

Brand Name:

-

GELGOOG

-

Dimension(L*W*H):

-

8m*4m

-

Weight:

-

1200 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V ,Customized

-

Power:

-

12 Kw, 67800w

-

product Name:

-

French Fries Production Line Semi Automated French Fries Machine

-

Capacity:

-

70KG/H

-

Material:

-

304 Stainless Steel

-

Application:

-

French Fries

-

Heating Source:

-

Electric

-

Applicable Industries:

-

Food & Beverage Factory

-

After Warranty Service:

-

Video technical support

Product Description

Introduction of Small Scale French Fries Production Line

This processing line absorbs the essence of similar equipment, retains advantages of large equipment and concentrates it, designed and developed with reference to feedback information from users all over the country. The complete set of equipment consists of cleaning and peeling, cutting, blanching, dewatering, oil-water mixed frying, deoiling, seasoning, packaging and auxiliary equipment.

RELATED PRODUCT

PRODUCT PARAMETER

|

No.

|

Name

|

Power

|

Dimension

|

|

1

|

Potato Washer Peeler

|

1.5kw

|

1800*850*800 mm

|

|

2

|

Potato Cutting Machine

|

1.1kw

|

950*900*1000 mm

|

|

3

|

Blanching Machine

|

24kw

|

1000*500*800 mm

|

|

4

|

Dewatering Machine

|

1.5kw

|

1000*500*850 mm

|

|

5

|

French Fries Frying Machine

|

36kw

|

500*500*900 mm

|

|

6

|

Deoiling Machine

|

1.5kw

|

1000*600*850 mm

|

|

7

|

Octagonal Flavoring Machine

|

1.1kw

|

1100*800*1300 mm

|

|

8

|

Vacuum Packing Machine

|

1.1kw

|

600*600*850 mm

|

MACHINE DETAILS

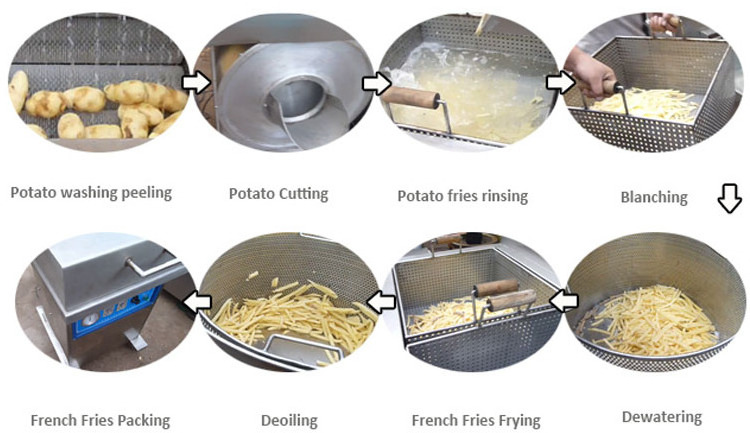

Main Equipment of Small Scale French Fries Production Line

1.

Potato Washing and Peeling Machine:

Use corundum-lined or brush-type machine to complete cleaning and peeling work at the same time.

2. Potato Cutting Machine:

Cut potato into slices or strips, and the thickness can be adjusted at will.

3. Blanching machine:

Rinse the cut potato chips and protect the color.

4. Dewatering machine:

Dewatering by centrifugal force, which can greatly shorten frying time.

5. Oil-water Mixing Fryer:

Used for frying potato french fries. Oil temperature is precisely controlled, thus ensuring the quality and taste of fried food.

6.

Deoiling Machine:

Centrifugal deoiler, deoiling freshly fried potato chips and French fries, overcoming the high oil content of fried food and improving taste.

7. Octagonal Seasoning Machine:

The French fries are turned in the rotation of the drum, and the seasonings are added by sprinkling or spraying, seasoning uniformly.

8. Nitrogen-filling packaging machine:

When packaging, flushing nitrogen into the packaging bag can effectively prevent potato chips from being broken and prolong the shelf life. Inflation, packaging, and coding are completed at one time.

COMPANY PROFILE

CONTACT OUR SERVICE

Hot Searches