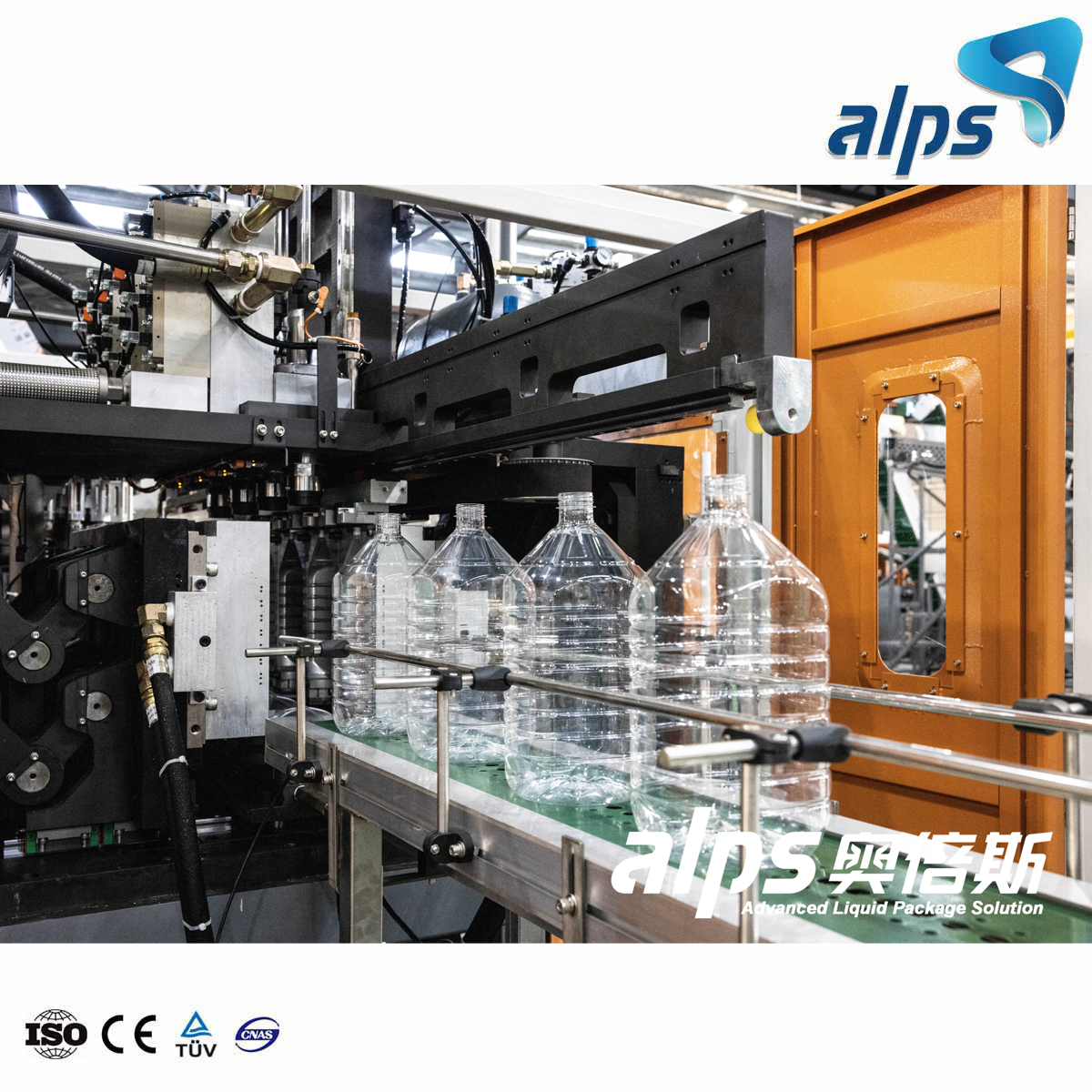

The two–step high speed automatic linear blow molding machines which are applicable in a wide range of PET packaging practice, such as for beverages, edible oil, food, pharmaceutical products and cosmetics,etc. With more than 10 years experience in developing and producing blow molding machine as well as the advanced technology absorbed domestic and abroad, we have developed with our constant innovation dozens of high speed and high precision equipments which have won the top reputation in the filed.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Alps

-

Year:

-

2019

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

4.5*2.2*2.3m

-

Hollow part volume:

-

100ml to 2L

-

Clamping Force (kN):

-

480

-

Power (kW):

-

60

-

Weight (KG):

-

5500 KG

-

Keywords:

-

Bottle blow molding machine

-

Capacity:

-

2000bph~12000bph

-

Max bottle size:

-

2L

-

Suitable bottle:

-

PET drinking Bottle

-

Bottle material:

-

PET preform

-

Model:

-

2 / 4 / 6 / 8 Cavities

-

Function:

-

PET stretch blowing

-

Advantage:

-

Full electrical servo system

-

Servo motors:

-

YASKAWA (Japan)

Quick Details

-

Neck Diameter(mm):

-

28 mm

-

Max.Bottle Diameter(mm):

-

120 mm

-

Max.Bottle Height(mm):

-

330 mm

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Alps

-

Year:

-

2019

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

4.5*2.2*2.3m

-

Hollow part volume:

-

100ml to 2L

-

Clamping Force (kN):

-

480

-

Power (kW):

-

60

-

Weight (KG):

-

5500 KG

-

Keywords:

-

Bottle blow molding machine

-

Capacity:

-

2000bph~12000bph

-

Max bottle size:

-

2L

-

Suitable bottle:

-

PET drinking Bottle

-

Bottle material:

-

PET preform

-

Model:

-

2 / 4 / 6 / 8 Cavities

-

Function:

-

PET stretch blowing

-

Advantage:

-

Full electrical servo system

-

Servo motors:

-

YASKAWA (Japan)

Full Automatic Plastic Water Juice CSD Beverage PET Bottle Blowing Making Machine Stretch Blow Molding Plant Price

Beverage Bottle

Food & Daily Chemical bottle

Food oil bottle / Cleaning liquid bottle / Cosmetic bottle /

medical bottle ....

|

Technical parameter: PET bottle blow machine

|

|

|

|

|

||||

|

Model

|

BL-A2

|

BL-A4S

|

BL-A6S

|

BL-A9S

|

||||

|

Cavities

|

2cavities

|

4cavities

|

6cavities

|

8cavities

|

||||

|

Capacity

|

2000 bottles/hour

|

6000 bottles/hour

|

9000 bottles/hour

|

12000 bottles/hour

|

||||

|

Application

|

oil bottle with handle blowing machine

|

|

|

|

||||

|

Bottle volume

|

0.1-2L

|

0.1-2L

|

0.1-2L

|

0.1-2L

|

||||

|

Body diameter

|

<100mm

|

<100mm

|

<100mm

|

<100mm

|

||||

|

Max bottle height

|

<310mm

|

<310mm

|

<310mm

|

<310mm

|

||||

|

Main power

|

25KW

|

49KW

|

73KW

|

85KW

|

||||

|

Hp air compressor

|

2.0 m3/min

|

2.4 m3/min

|

3.6m3/min

|

6.0m3/min

|

||||

|

LP air compressor

|

1.0 m3/min

|

1.6 m3/min

|

2.0 m3/min

|

2.0 m3/min

|

||||

|

Machine sizes

|

1.9*1.3*2m

|

3.2*1.3*2m

|

3.9*1.3*2m

|

4.5*1.3*2m

|

||||

|

Weight

|

2000kg

|

3600kg

|

3800kg

|

4500kg

|

||||

Main Features

i. The man-machine interface is easy to operate. Everything is computerized, including temperature adjustment and preform distribution.

ii. Preform unscrambling, loading, bottle handling and ordering are all operated by stainless steel manipulator automatically without a second contamination.

iii. The circulating chilling water system can protect the bottle neck against deformation when the preform is being heated.

iv.The homothermal heater adopts auto reflection and closed loop adjusting system which have the power supplied constantly in proportion, not affected by the fluctuation of voltage. The conveying chain is short pitched and paratactic, which helps to realize slow heating and low power consumption. As a result, the preform can be heated evenly and easy to blow.

iv. The positioned installation of molds makes it possible to change molds easily within 30 minutes.

v. All the critical parts we use for the machines, such as the electrical, hydraulic and pneumatic components, servo motor, etc, are famous branded parts imported from Japan, USA and Europe,which ensures the stability and long life of our equipments.

Stepping mechanism:

Type :

Servo motor drive

Brand: Yaskawa (Japan)

Servo motor's synchronical high speed and precise positioning. Slide stepping by orbit is swift and stable with less cycle time and higher efficiency.

Mold movement mechanism

Type :

Servo motor drive

Brand:

Yaskawa (Japan)

Ensures that the series of the mold motions are simple, accurate, consistent and speedy, making cycle time 0.3~0.5 seconds.

Stretching mechanism & Mould

Type:

Servo motor drive

Brand:

Yaskawa (Japan)

Ensures the synchronicity of the motion of the rods and makes it easier to do adjustment prior to production.

Heating tunnel

Type:

Eco friendly & Energy save

Brand:

Lianggu (China)

Each lamp pipe in the heater can be controlled individually. Moreover, the heaters are equipped with the converter controlled circulating air cooling system that can keep the temperature constant inside the heater and preforms heated consistently

|

Name

|

Brand & Original

|

|

PLC

|

Omron (Japan)

|

|

Servo Motor

|

Yaskawa (Japan)

|

|

Speed Reducer

|

NEUGART (Germany)

|

|

High Pressure Blowing Valve

|

PARKER(U.S.A.)

|

|

Cylinder

|

Rexroth(Germany)

|

|

AC Contactor, Thermal Relay

|

Schneider (France)

|

|

Silicon Control

|

Semikron (Germany)

|

|

Intelligent Voltage Regulator

|

Omron (Japan)

|