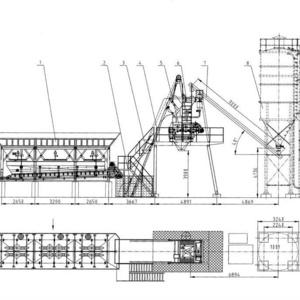

1. 3-bin aggregate batching machine;

2. JS1000 twin-shaft concrete mixer;

3. Water, cement and additive scales;

4. Two sets 70T

horizontal cement silo;

horizontal cement silo;

5. Two sets 273mm*10m screw conveyor;

6. One set air compressor;

7. Container type control room with air

conditioner;

conditioner;

8. Fully automatic computer control system in English.

Welcome to contact us for details.