Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

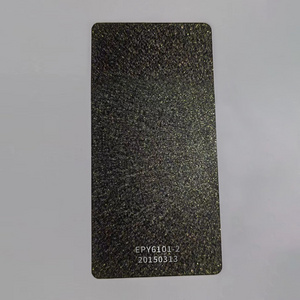

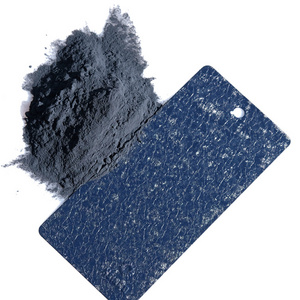

Epoxy powder coating

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HANNA POWDERS

-

Model Number:

-

HNP19, PRD-RAL

-

Thermosetting:

-

Thermosetting

-

Product name:

-

Holographic Glitter Powder for Epoxy Floor Coating

-

Texture:

-

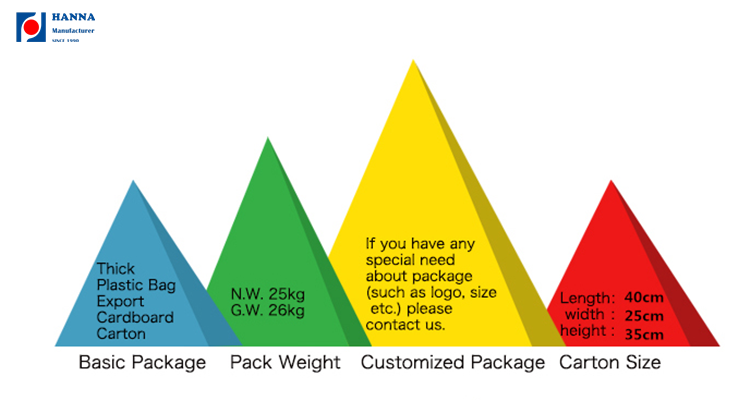

Smooth, Wrinkle,Cotton, Etc

-

Glossy:

-

High Gloss, Matt, Low Gloss

-

Curing schedule:

-

180-200℃,15-20mins

-

Finish:

-

Smooth or texture

-

Application:

-

Metal Etc MDF

-

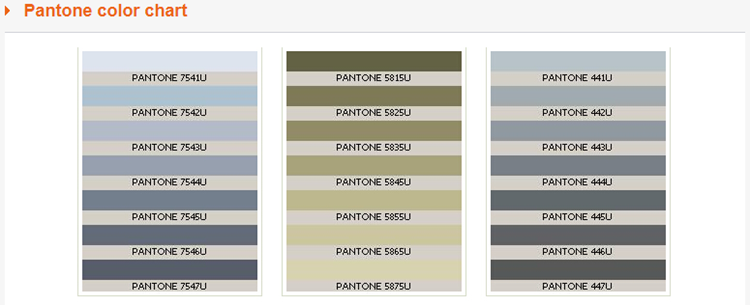

Package:

-

25kg/paper Carton/custom

Quick Details

-

CAS No.:

-

Epoxy powder coating

-

Other Names:

-

Epoxy powder coating

-

MF:

-

Epoxy powder coating

-

EINECS No.:

-

Epoxy powder coating

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HANNA POWDERS

-

Model Number:

-

HNP19, PRD-RAL

-

Thermosetting:

-

Thermosetting

-

Product name:

-

Holographic Glitter Powder for Epoxy Floor Coating

-

Texture:

-

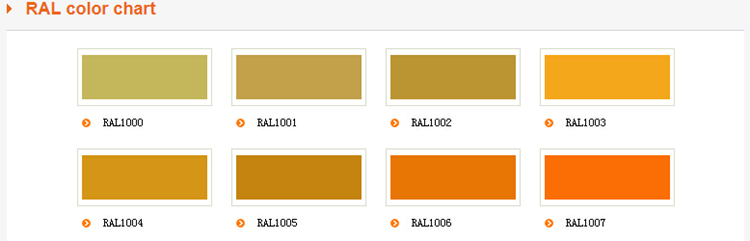

Smooth, Wrinkle,Cotton, Etc

-

Glossy:

-

High Gloss, Matt, Low Gloss

-

Curing schedule:

-

180-200℃,15-20mins

-

Finish:

-

Smooth or texture

-

Application:

-

Metal Etc MDF

-

Package:

-

25kg/paper Carton/custom

Holographic Glitter Powder for Epoxy Floor Coating

What is Powder Coating?

Powder coating is a new type of 100% solid powder coating which does not contain solvents. With no solvent, no pollution, energy and resources saving, recycling, environmental protection, higher performance, low health risk to workforce, economical advantages etc. Most powder coating is used by electrostatic spraying on metal surface, and then cure in oven, eventually form a solid layer.

Applications of Product

♦Electrical Household Appliances ♦Aerospace Area

♦Automotive Electronics ♦Fitness Equipment

♦Track Traffic ♦ Medical Devices

♦Petroleum Pipes, Valve ♦Tools & Hardware

♦LED Lights, Outdoor Lamps ♦Radiator & Heat Sink

♦Glass Decoration ♦External Facilities

• Epoxy powder coating is a series of epoxy based powder coating designed to give optimum mechanical properties and exceptional protective qualities on components and fabrications where long term exposure to ultra violet light or exterior weathering is not anticipated.

• This series are available in a wide range of colors with different gloss and texture. Epoxy powder coating is perfect for indoor use.

MAIN PROPERTIES:

• Excellent corrosion protection;

• Excellent chemical resistance;

• High mechanical performance ;

• Suitable for interior use.

POWDER CHARACTERISTIC

• Chemistry: Epoxy

• Particle size: Suitable for electrostatic spraying

• Specific gravity: 1.2-1.8g/cm3 up to colors

• Curing schedule(object temp.): 160℃-180℃/10-15minutes;200℃/5-10minutes;

• Storage: Dry ventilation conditions below 30℃

COATING PERFORMANCE

Type A - 200°C (work piece temperature), 15 minutes (flat or Matt)

Type B -180°C (work piece temperature), 15 minutes (highlight)

Type C -140°C (work piece temperature), 15 minutes (highlight)

|

Inspection Item |

Test Standard or Method |

Test Indicator |

|||

|

Type A |

Type B ,C |

||||

|

Impact resistance |

ISO6272 |

GB/T1732-1993 |

40cm |

50cm |

|

|

Cupping test |

ISO1520 |

GB/T9753-1988 |

5mm |

8mm |

|

|

Adhesion(Planning grid method) |

ISO2409 |

GB/T9286-1998 |

Grade 0 |

||

|

Crook |

ISO1519 |

GB/T6742-1986 |

3mm |

2mm |

|

|

Pencil hardness |

ASTMD3363 |

GB/T6739-1996 |

1H-2H |

||

|

Salt test |

ISO7253 |

GB/T1771-1991 |

> 500 hours |

||

|

Heat test |

ISO6270 |

GB/T1740-1979 |

> 1000 hours |

||

|

Heat resistance |

100°C/24 hours (white) |

Paul Light character (best) :

|

|||

|

Remark |

1, The above test use cold-rolled steel(thichness:0.8mm) to remove rust,oil. Film thickness: 50-70um. 2, All the indicators of film features will be down lightly depending on reducing of luster. |

||||