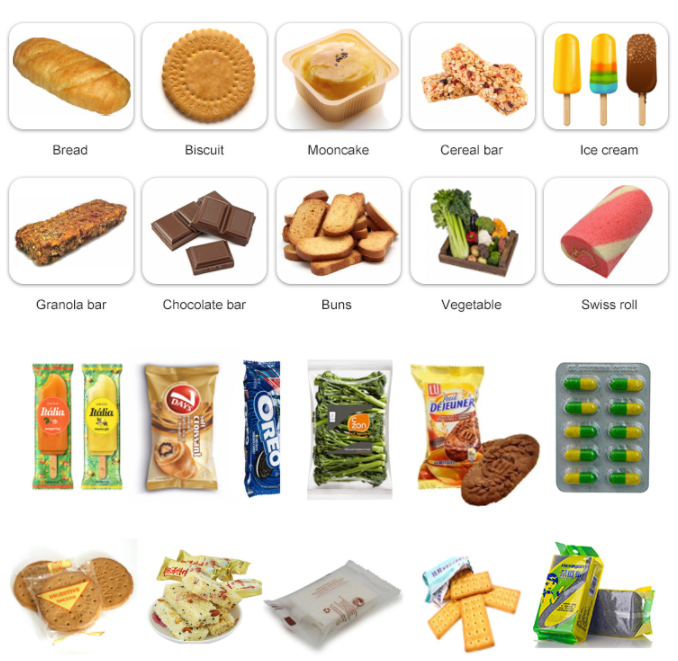

The machine is suitable for a variety of packaging styles, optional packaging, widely used in food, medicine, chemical, daily necessities, hardware and other industries.We can customize the machine model according to your products

.

Just Tell us : Weight or Bag Size required.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

China

-

Product name:

-

Pillow packing machine

-

Packing speed:

-

40-120pcs/min

-

Max film width:

-

80-220mm

-

Screen:

-

Touch screen

-

Packaging material:

-

OPP,CPP,PT/TE,KOP/CPP & so on

-

Weight:

-

550kg

-

Feature:

-

With printing

-

Control system:

-

Servo control system

-

Film thickness:

-

30-70mm

-

Model:

-

100/300/400/500/600

-

Certification:

-

CE

Quick Details

-

Function:

-

Wrapping, Labeling, Sealing

-

Packaging Type:

-

Cartons, CANS, Bottles, Barrel, Stand-up Pouch, Bags, Film, Foil, Pouch, Capsule, case

-

Packaging Material:

-

Plastic, Paper

-

Voltage:

-

220V

-

Place of Origin:

-

China

-

Product name:

-

Pillow packing machine

-

Packing speed:

-

40-120pcs/min

-

Max film width:

-

80-220mm

-

Screen:

-

Touch screen

-

Packaging material:

-

OPP,CPP,PT/TE,KOP/CPP & so on

-

Weight:

-

550kg

-

Feature:

-

With printing

-

Control system:

-

Servo control system

-

Film thickness:

-

30-70mm

-

Model:

-

100/300/400/500/600

-

Certification:

-

CE

Product Description

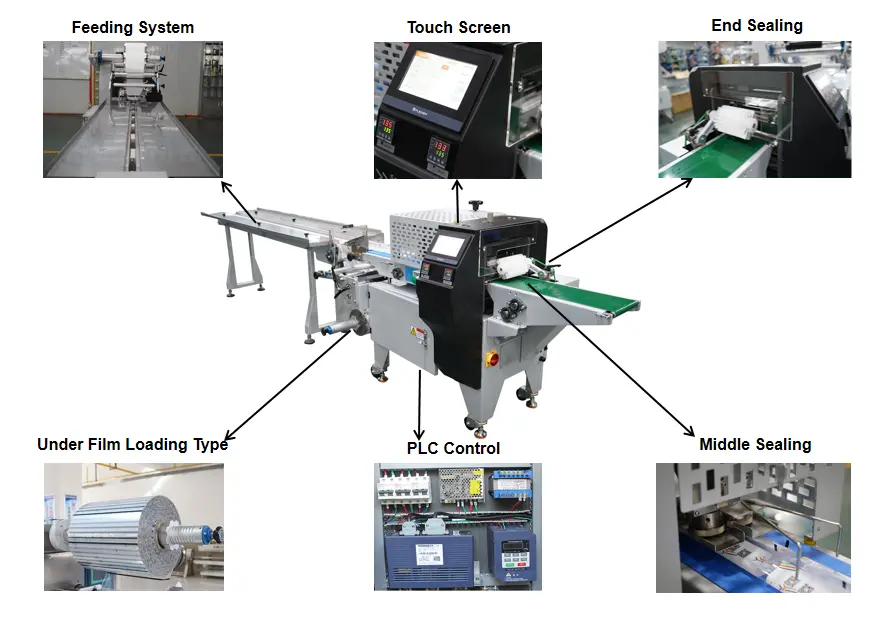

Automatic Pillow Packing Machine

Horizontal pillow packing machine with high packing efficiency and servo control system t

o achieve

infinitely variable speed.Do not worry and feel free to text us. Y

ifei will g

ive you the best quality plan

.

With the most real and effective way to provide you with comfortable service. High quality and attentive serviceis the Yifei corporate culture.

Featurs:

1)The pillow packing machine is widely used in food, medicine, d

aily necessities, chemical and other industries.

2)

This series of packaging machine is a stable performance, widely used models. PLC control servo control system, making the equipment failure rate is low, easy to adjust.

3)M

ore kinds of products can be packaged in one machine. Packing speed up to 100 bags

a minute, get rid of the traditional machine low efficiency shortcomings. More efficient work and longer machine life.

a minute, get rid of the traditional machine low efficiency shortcomings. More efficient work and longer machine life.

Product param

eter :

|

Model

|

YF-100

|

|

Packaging speed

|

20-200pcs/min

|

|

Bag size(L*W*H)

|

70-260*30-90*3-35

|

|

Packaging film width

|

80-220mm

|

|

Packaging material

|

OPP、CPP、PT/TE、KOP/CPP & so on

|

|

Machine size

|

4100*1000*1500

|

|

Heating power

|

3.5KW

|

|

Motor power

|

0.55+0.75KW

|

|

Total power

|

4.8kw

|

|

Machine weigth

|

550kg

|

|

Model

|

YF-300

|

YF-320

|

YF-350

|

||

|

Packaging speed

|

30-200pcs/min

|

|

|

||

|

Bag size

(L*W*H)

|

75-240*30-140*3-50mm

|

100-320*30-160*5-70mm

|

130-400*50-160*3-70mm

|

||

|

Packaging Film Width

|

60-300mm

|

80-320mm

|

80-350mm

|

||

|

Packaging material

|

OPP、CPP、PT/TE、KOP/CPP & so on

|

|

|

||

|

Machine size

(L*W*H)

|

4000*950*1600mm

|

4000*950*1600

|

4000*950*1600

|

||

|

Heating power

|

3.5KW

|

|

|

||

|

Motor power

|

0.55*0.75KW

|

|

|

||

|

Total power

|

4.8KW

|

|

|

||

|

Weigth

|

600kg

|

650kg

|

630kg

|

||

|

Model

|

YF-400

|

YF-420

|

YF-450

|

||

|

Packaging speed

|

40-120pcs/min

|

|

|

||

|

Bag size

(L*W*H)

|

130-350*30-160*5-80mm

|

130-350*30-160*5-80mm

|

160-400*30-180*5-80mm

|

||

|

Packaging Film width

|

90-400mm

|

90-420mm

|

90-450mm

|

||

|

Packaging Film thickness

|

30-70mm

|

|

|

||

|

Film rolling size

|

Outside diameter≤300mm ,inside diameter≤75mm

|

|

|

||

|

Packaging material

|

OPP、CPP、PT/TE、KOP/CPP & so on

|

|

|

||

|

Machine size

(L*W*H)

|

4100*950*1700mm

|

|

5000*950*1700mm

|

||

|

Power

|

200V/50HZ

|

|

|

||

|

Voltage

|

5.5KW

|

|

|

||

|

Weigth

|

650kg

|

680kg

|

700kg

|

||

|

Model

|

YF-500

(Center distance114)

|

YF-500

(Center distance150)

|

YF-600

|

||

|

Packaging speed

|

25-150pcs/min

|

|

40-120pcs/min

|

||

|

Bag size

(L*W*H)

|

100-400*240*55mm

|

100-750*240*80mm

|

150-750*240*30-80mm

|

||

|

Max Film width

|

500mm

|

90-420mm

|

600mm

|

||

|

Packaging material

|

OPP、CPP、PT/TE、KOP/CPP & so on

|

|

|

||

|

Machine size

(L*W*H)

|

4200*1005*1470mm

|

4000*950*1600

|

4200*800*1600mm

|

||

|

Voltage

|

6KW

|

|

6KW

|

||

|

Weigth

|

850kg

|

680kg

|

450kg

|

||

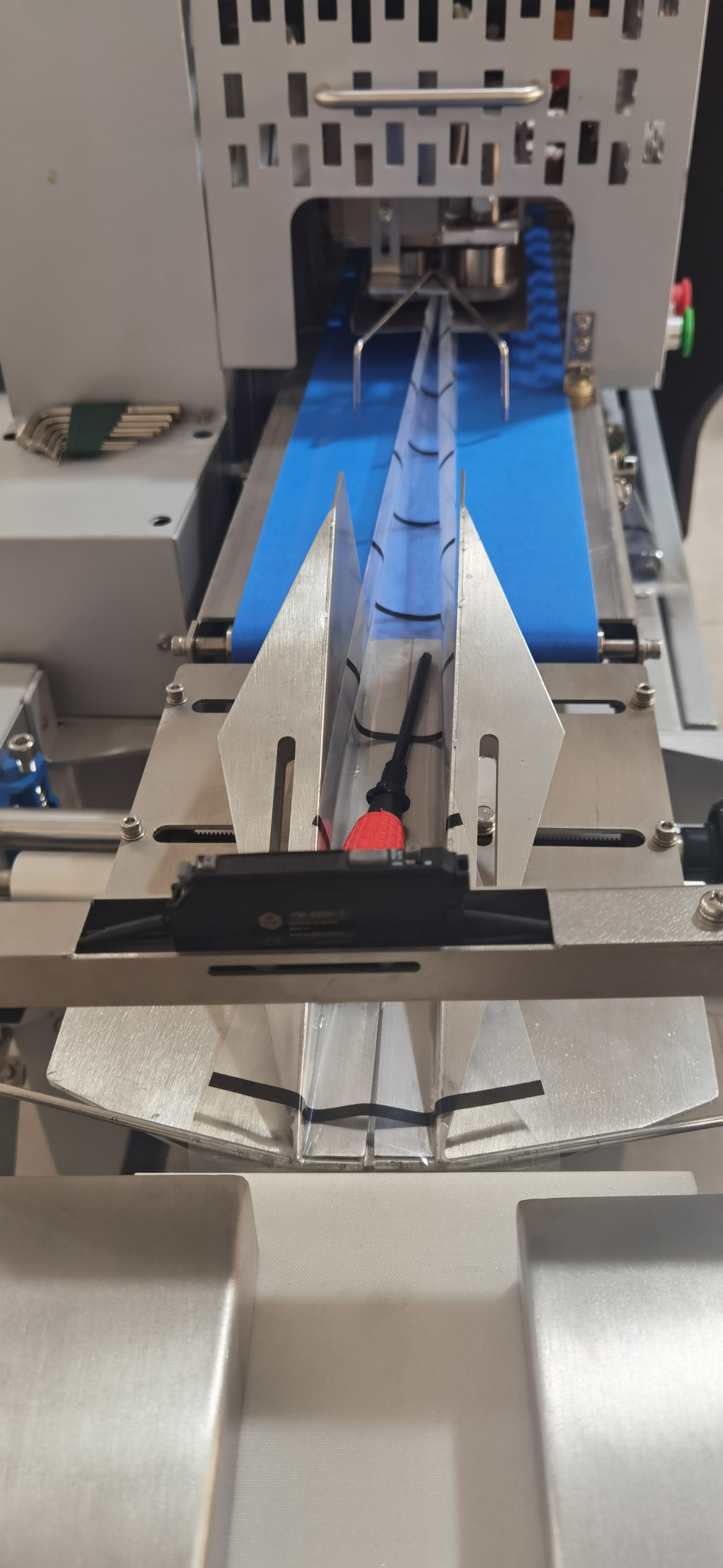

Under the film packaging

more sensitive, photoelectric sensing items stop packaging, no empty bag more intelligent and more assured.

Up film packaging

Achieve 100 bags per minute productivity, solve the problem of output. Stainless steel transfer panel, more durable, non-corrosive, suitable for viscous packaging.

Optional devices:

code typing machine, inflatable device, cake dropping device; Food processor, guide bar, wool sweeper and Angle holder.

Sample

Product Details

Touch intelligent control screen

control the packaging process, easy to operate, with digital display independent double temperature control tabulation, real-time display of packaging film temperature.

L

inkage film axis

adopts multi-linkage film axis to coordinate the film pulling link, adapt to more film material, film rolling is more smooth.

Bag seal cutting area

before and after the packaging seal. Precise cutting temperature, avoid curling hole phenomenon, improve efficiency, increase production

The film pressingdevice

makes the packaging size of the product accurate, not easy to curl the edge of the leak phenomenon, to achieve the exquisite packaging effect.

More Details

Exhibition

Hot Searches