- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Leadworld

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

1500 KG

-

Product name:

-

Automatic Oil Filling Production Line

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Filling Capping Labeling Packaging

-

Bottle type:

-

PET Plastic Bottle

-

Keywords:

-

Fillng Machine

-

Processing Types:

-

Automatic Bottle Filling Sealing Machine

-

Suitable for:

-

Paste Liquid Cream

-

Filling speed:

-

5-25Bottles/min

-

Function:

-

Washing Filling Capping

Quick Details

-

Machinery Capacity:

-

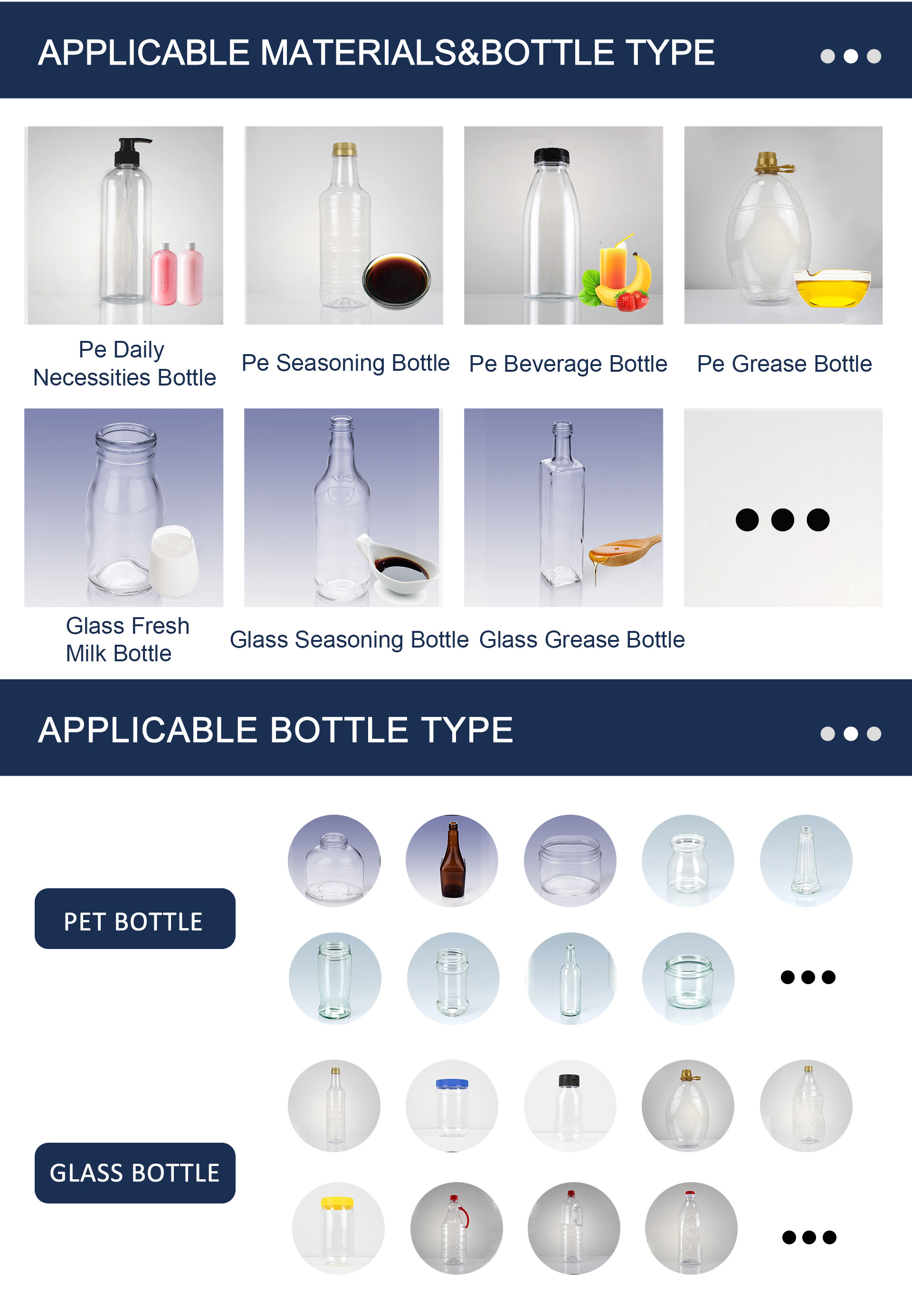

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH, can be customized

-

Packaging Material:

-

Plastic, Paper, Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Powder, Paste

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Leadworld

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

1500 KG

-

Product name:

-

Automatic Oil Filling Production Line

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Filling Capping Labeling Packaging

-

Bottle type:

-

PET Plastic Bottle

-

Keywords:

-

Fillng Machine

-

Processing Types:

-

Automatic Bottle Filling Sealing Machine

-

Suitable for:

-

Paste Liquid Cream

-

Filling speed:

-

5-25Bottles/min

-

Function:

-

Washing Filling Capping

Product Description

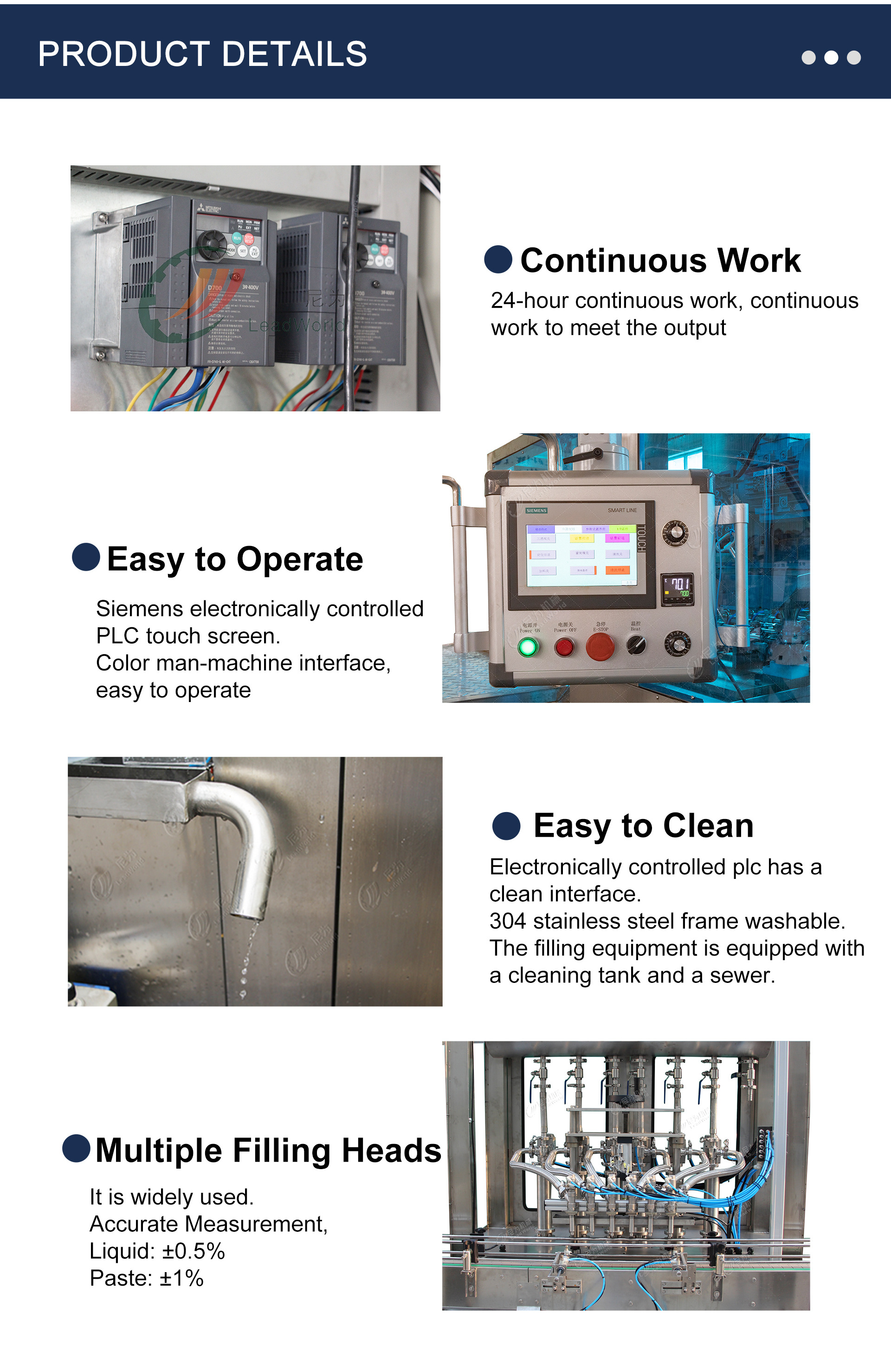

Filling Machine is widely used as sacuces,food,daily chemicals,etc,can fill hot sauce,tomato sauce,honey,mushroom sauce,salad dressing,pulp-containning beverages,etc,Using servo control,high measurement accuracy and stableoperation.

|

COMMON PROBLEMS OFCUSTOMIZED PRODUCTION LINE

|

OUR SOLUTION

|

|

FILLING ACCURACYIS NOTENOUGH.

|

Filling Accuracy 0.5%

|

|

MULTIPLE BOTTLE TYPES NEED

|

Multiple Bottle Types and one FillingMachine.

|

|

CLEANING TROUBLE

|

The Equipment Can Be Washed Directlyand The Protection Level is High

|

|

THE OPERATION OF THEEQUIPMENT IS UNSTABLE

|

Select Siemens,Danfoss, Schneider.Electrical Components, Stable Operation

|

|

AFTER-SALES RESPONSEIS NOT TIMELY

|

Have Their Own Design Team, ElectricalEngineer and After-sales Team, ResponseTime 24 hours

|

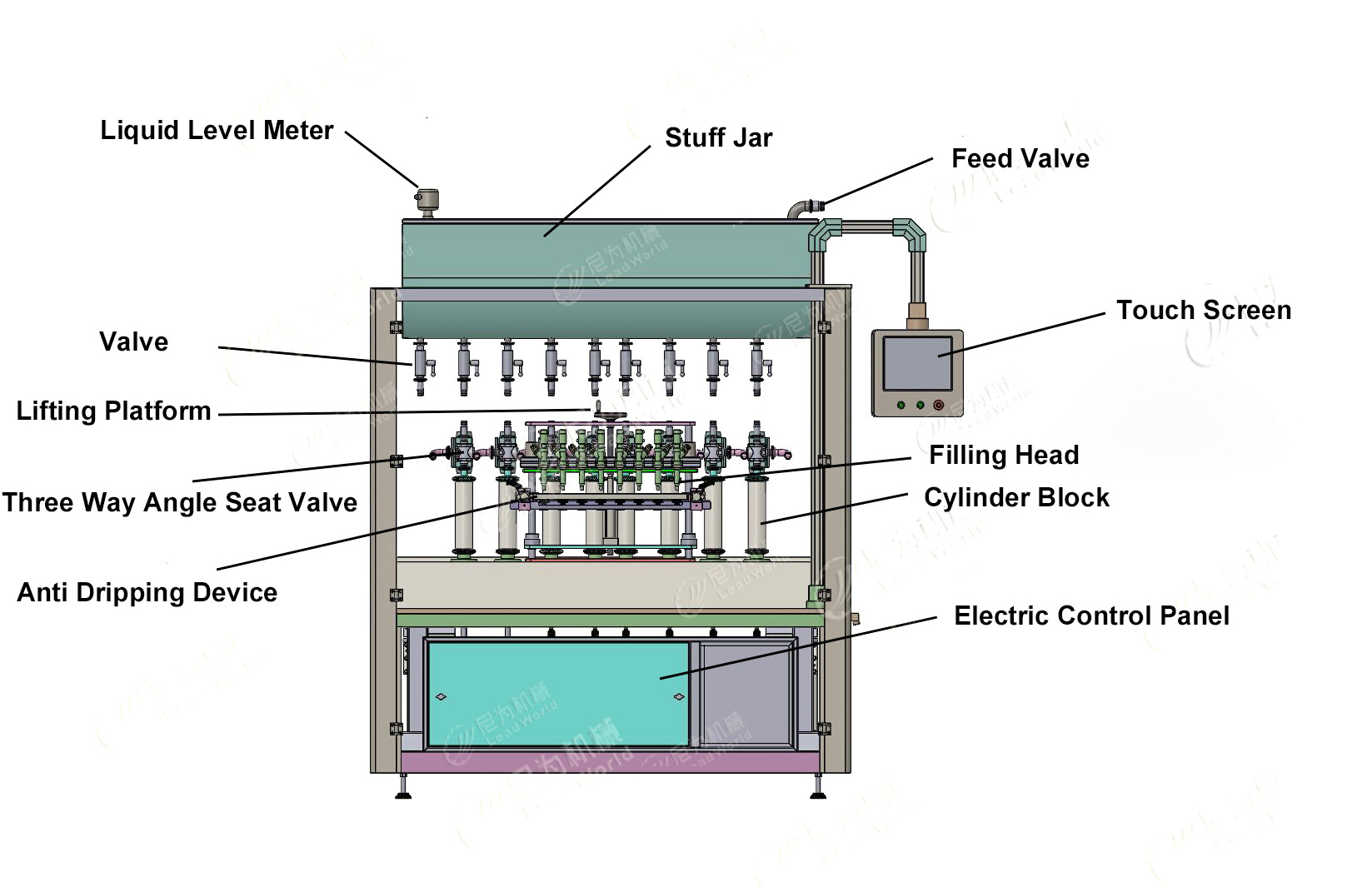

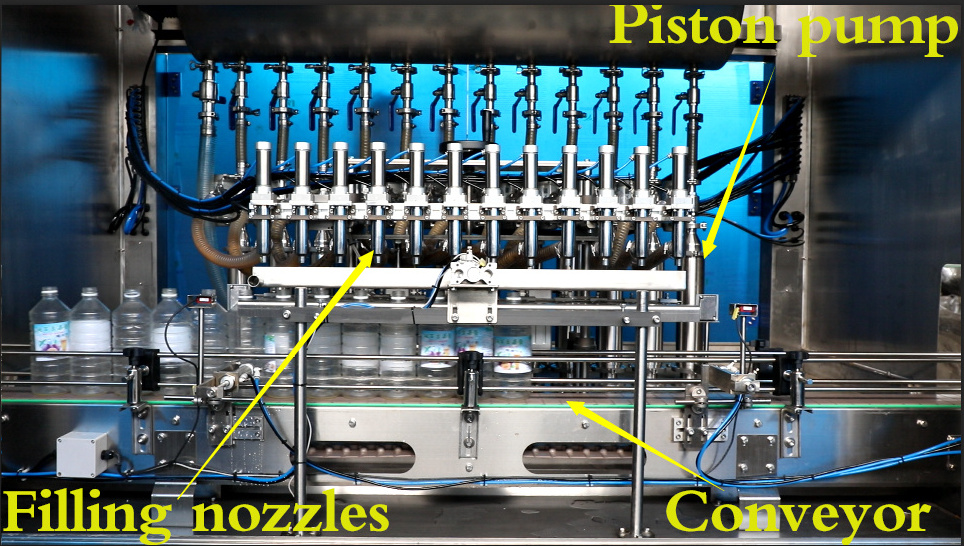

Features:

1. Vacuum Preventing Leaking System

2. No Bottle or Lack of Bottle, No Filling System

3. Photoelectric Sensor, Mechatronics Filling Adjustment System

4. Photoelectric Sensor, Material Level Control Feeding System

5. Stainless Steel Frame, Plexiglass as Security Cover

6. Control System: PLC/Electronic-Pneumatic Controlled

7. Operation Panel: "Intelligent" Colorful Touch Screen

8. Filling Accuracy:+-0.5%

9. Capacity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

10. Container transport:Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric sensor.

Technical parameters:

|

Model

|

LW--4A

|

|

Filling Volume

|

200ml--1000ml can customize

|

|

Air Pressure

|

3-5kg/cm2

|

|

Total Power

|

AC380V, 50/60HZ

|

|

Capacity

|

0--1920 bottles/h customize

|

|

Filling Heads

|

4

|

|

Material

|

SUS304

|

Accessories list

|

Accessories name

|

|

Brand name

|

|

|

|||

|

PLC

|

|

Siemens German

|

|

|

|||

|

electrical elements

|

|

Schneider France

|

|

|

|||

|

pneumatic element

|

|

AirTac Taiwan

|

|

|

|||

|

amphenol connector

|

|

Weidmuller German

|

|

|

|||

|

Transducer

|

|

Danfoss Denmark

|

|

|

|||

|

Bearing

|

|

IGUS German

|

|

|

|||

|

Photoelectricity

|

|

KEYENCE Japan it is waterproof

|

|

|

|||

|

Piston

|

|

Taiwan, heat-resistant, oil proof

|

|

|

|||

Hot Searches