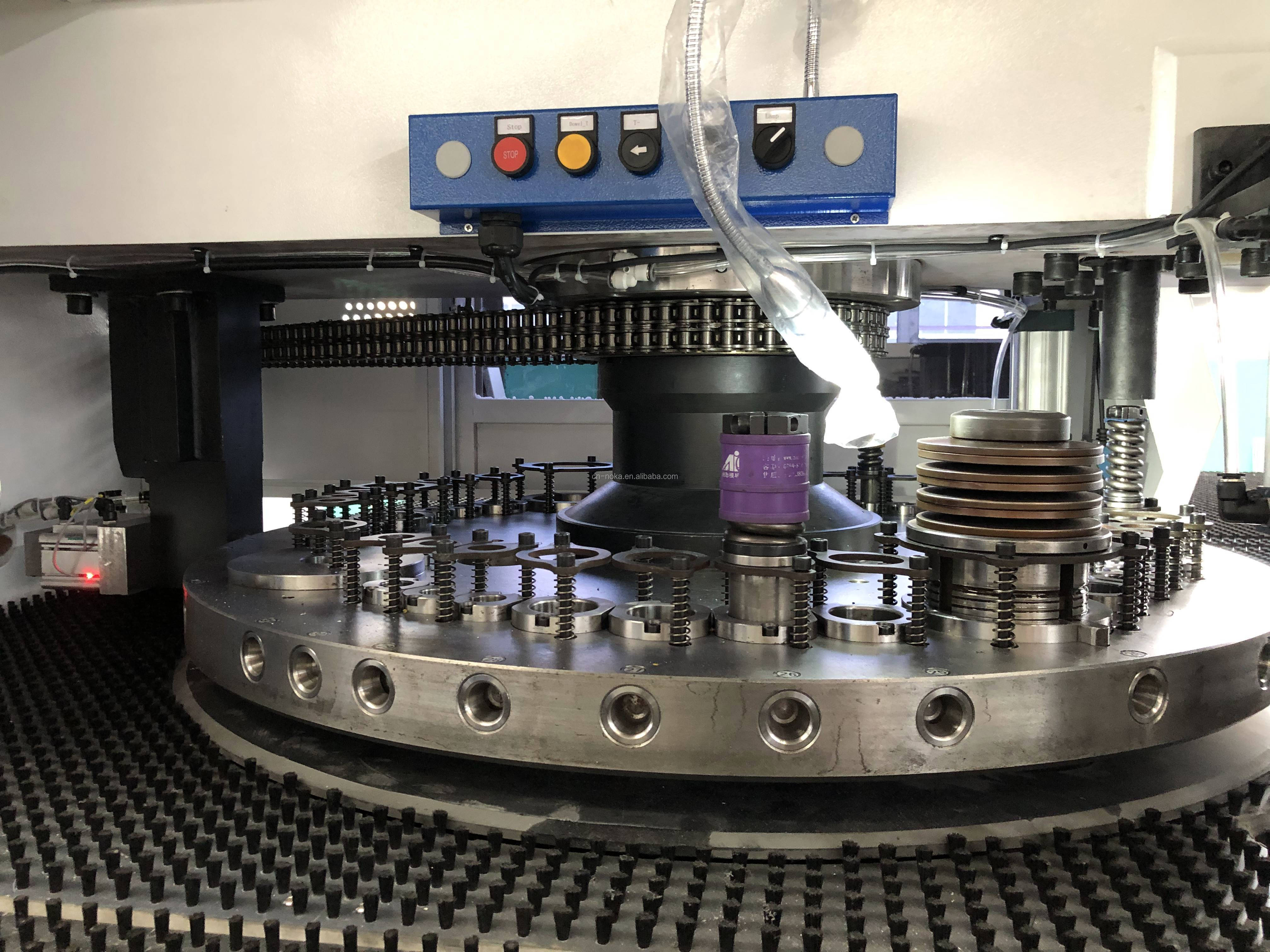

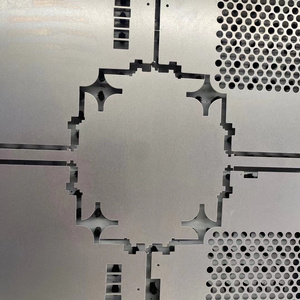

Name: Mold Turntable

The die hole and the side positioning hole on the turntable are formed at one time, which ensures the positioning index of the side hole and the precision of the die hole on the turntable punch turntable.