- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V, 220V/380V

-

Power:

-

36KW

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

3800*1650*1650

-

Name:

-

Food Steam Retort

-

Usage:

-

Extend Food Shelf Life

-

Material:

-

SUS 304/316

-

Use:

-

Package Food Sterilization

-

Application:

-

Canned Meat Sterilization

-

Heating type:

-

Electric/Steam Heating

-

Sterilizing Way:

-

Steam Spray/Water Immersion

-

Certification:

-

CE ISO

Quick Details

-

Marketing Type:

-

Factory Outlet

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JINGYE

-

Voltage:

-

380V/415V, 220V/380V

-

Power:

-

36KW

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

3800*1650*1650

-

Name:

-

Food Steam Retort

-

Usage:

-

Extend Food Shelf Life

-

Material:

-

SUS 304/316

-

Use:

-

Package Food Sterilization

-

Application:

-

Canned Meat Sterilization

-

Heating type:

-

Electric/Steam Heating

-

Sterilizing Way:

-

Steam Spray/Water Immersion

-

Certification:

-

CE ISO

Product Details

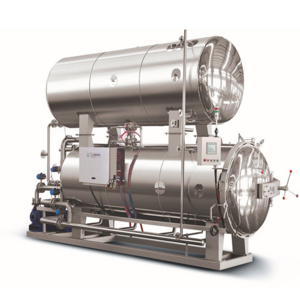

Sterilization Retort

Jingye

a

utoclaves are widely used in food, beverage, dairy industry, medicine and other fields. Autoclaves can extend the shelf life of food, the need for high temperature short time sterilization of food or sterilization, not only kill pathogens in food possible, while maintaining an important food nutrients and food color, flavor is not compromised. Sterilization retort consist of the cylinder, lid, open the device, locking wedge, safety interlocks, track, sterilization baskets, steam nozzle, nozzle structure and several other components.

Scope of application

A full functional autoclave is applicable to all kinds of high temperature resistant packaging material.

1. Bottle of PP or HDPE

2. Pouch packaging:Aluminum foll bags ,transparent bags,vacuum bags ,high temperature retort pouch

etc.

3. Metal containers:tin cans,aluminum cans.

4. Glass bottles.

1. Bottle of PP or HDPE

2. Pouch packaging:Aluminum foll bags ,transparent bags,vacuum bags ,high temperature retort pouch

etc.

3. Metal containers:tin cans,aluminum cans.

4. Glass bottles.

Main Features

A. Suitable for all heat resistant package material including glass container;

B. Safety interlock Device for quick closure of retort, to ensure the safety of operator;

C. Quick heating, only need about 6-12 minutes to reach the sterilization temperature;

D. Uniform heat distribution, no blind angle;

E. Adopting the multi-phase process for rising and dropping of temperature, minimize the temperature difference between the

surface and center of packed food, maintain the flavor and nutrition of food. Mild heating and cooling process can protect the fragile container and glass container;

F. Direct heating by steam and indirect cooling by continually recycling the water through the heat exchanger, avoiding secondary contamination to the food package;

G. Employing soft water for sterilization to avoid pollution to the surface of package; no special requirements for cooling water which reduce the cost of sterilization;

H. Siemens PLC automatic control system and touch screen, easy to operate;

I. Pressure control system can adjust the pressure in the tank automatically and precisely in case the packages break or deformation during sterilization process;

J. Monitoring temperature ensures food safety, saves energy, reduces production time and assists in providing the best quality product.

K. System will make alarm calls automatically when the temperature, the pressure, the water level, or any other kinds of error occur.

B. Safety interlock Device for quick closure of retort, to ensure the safety of operator;

C. Quick heating, only need about 6-12 minutes to reach the sterilization temperature;

D. Uniform heat distribution, no blind angle;

E. Adopting the multi-phase process for rising and dropping of temperature, minimize the temperature difference between the

surface and center of packed food, maintain the flavor and nutrition of food. Mild heating and cooling process can protect the fragile container and glass container;

F. Direct heating by steam and indirect cooling by continually recycling the water through the heat exchanger, avoiding secondary contamination to the food package;

G. Employing soft water for sterilization to avoid pollution to the surface of package; no special requirements for cooling water which reduce the cost of sterilization;

H. Siemens PLC automatic control system and touch screen, easy to operate;

I. Pressure control system can adjust the pressure in the tank automatically and precisely in case the packages break or deformation during sterilization process;

J. Monitoring temperature ensures food safety, saves energy, reduces production time and assists in providing the best quality product.

K. System will make alarm calls automatically when the temperature, the pressure, the water level, or any other kinds of error occur.

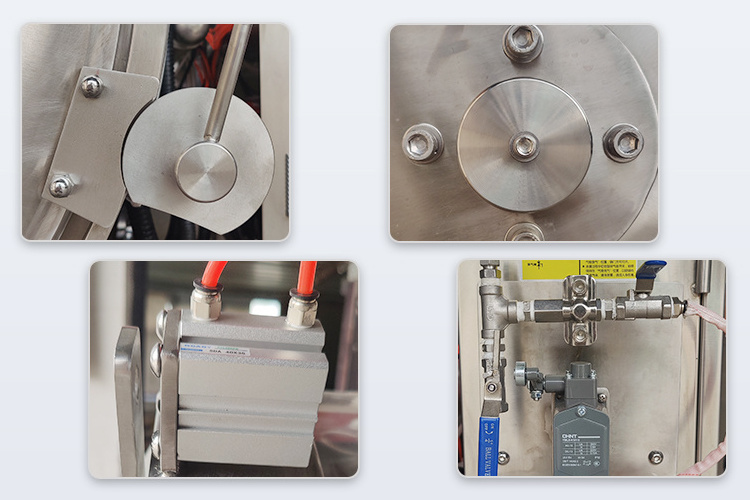

Detail Image

Application

Product Parameters

Product Structure Drawing

Hot Searches