- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jinghe

-

Model Number:

-

CR EMSG-1111

-

Type:

-

shielding material

-

Function:

-

Shielding and conductive

-

Application:

-

Communication base

-

Elastomer:

-

Silicone rubber

-

Curing method:

-

Heating curing

-

Volume resistivity:

-

≤0.006 Ohm-cm

-

Storage condition:

-

-20±2℃

-

Density:

-

2.0±0.1 g/cm³

-

Shielding effectiveness:

-

>100 -db

-

Tensile strength:

-

≥1.0 MPa

-

Shelf life:

-

3 months

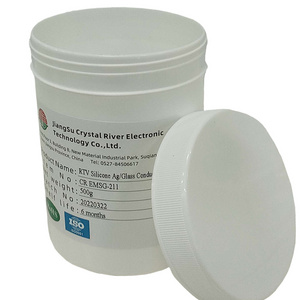

Quick Details

-

CAS No.:

-

N/A

-

Other Names:

-

HTV silicone conductive glue

-

MF:

-

MIXTURE

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jinghe

-

Model Number:

-

CR EMSG-1111

-

Type:

-

shielding material

-

Function:

-

Shielding and conductive

-

Application:

-

Communication base

-

Elastomer:

-

Silicone rubber

-

Curing method:

-

Heating curing

-

Volume resistivity:

-

≤0.006 Ohm-cm

-

Storage condition:

-

-20±2℃

-

Density:

-

2.0±0.1 g/cm³

-

Shielding effectiveness:

-

>100 -db

-

Tensile strength:

-

≥1.0 MPa

-

Shelf life:

-

3 months

Product Description

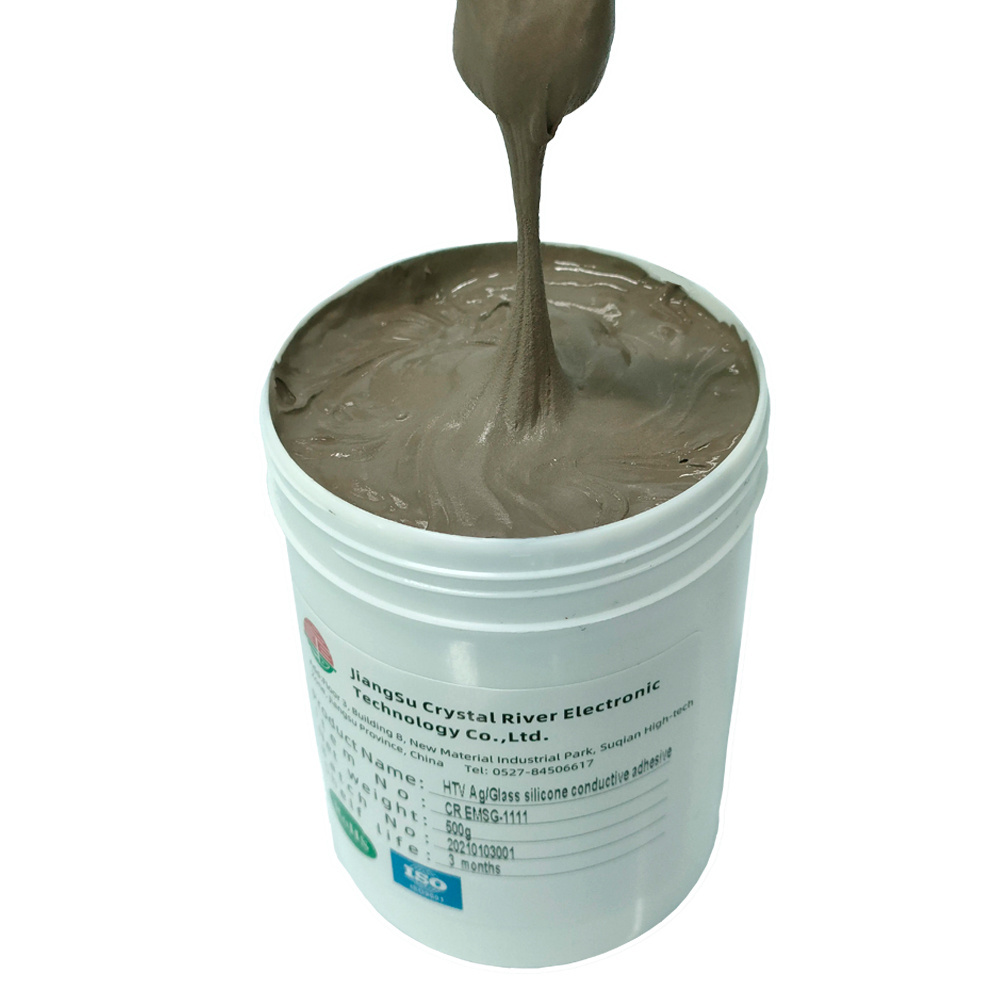

CR EMSG-111

series is silicone conductive glue filled with silver coated glass conductive powder. Available in one-part and two-part. It can be formed by FIP dispensing process. With low viscosity, it can guarantee short production cycle on any type of dispenser. At 150℃, it can be fully cured in 40 minutes, and the curing time shortens with the increase of temperature. It has excellent shielding effectiveness and good mechanical properties at the same time. Compared with Ag/Cu conductive glue, it has a higher cost performance and can be used in environments where the use conditions are not very harsh.

Properties

●Suitable for FIP dispensing saving labor and eliminating irrelevant waste

●Can be dispensed on metal or plastic substrates

●Excellent electromagnetic shielding performance

●Good thixotropy and adhesion

●Excellent electromagnetic shielding performance

●Good thixotropy and adhesion

Applications

●Electronic medical equipment

●Communication base station

●Entertainment electronics

●Automotive Electronics

●Entertainment electronics

●Automotive Electronics

Specification

|

Product performance

|

Test ways

|

unit

|

CR EMSG-1111

|

CR EMSG-1112

|

|

elastomer

|

/

|

/

|

Silicone rubber

|

Silicone rubber

|

|

Filler

|

/

|

/

|

Ag/Glass

|

Ag/Glass

|

|

Curing way

|

/

|

/

|

Heat curing

|

Heat curing

|

|

Component

|

/

|

/

|

One-component

|

Two-component

|

|

Mix proportion

|

/

|

/

|

/

|

1:1

|

|

Volume resistivity

|

MIL-DTL-83528C

|

Ω·cm

|

≤0.006

|

≤0.006

|

|

Shielding effectiveness (30MHz~10GHz), Min.

|

MIL-DTL-83528C

|

-dB

|

>100

|

>100

|

|

Density after curing, ±0.1

|

ASTM D792

|

g/cm

3

|

2.0±0.1

|

2.0±0.1

|

|

Shore A hardness, ±5

|

ASTM D2240

|

|

60±5

|

60±5

|

|

Tensile strength, Min.

|

ASTM D412

|

MPa

|

≥1.0

|

≥1.0

|

|

Elongation at break, Min

|

ASTM D412

|

%

|

>100

|

>100

|

|

Permanent deformation, Max.

|

ASTM D395

|

%

|

<65

|

<65

|

|

Adhesion @13# needle, Min.

|

/

|

N

|

>15

|

>15

|

|

Operating temperature

|

/

|

℃

|

-50~125

|

-50~125

|

|

Vulcanization @2mm thick

|

/

|

℃/min

|

150/40

|

150/40

|

|

Flame retardant grade

|

UL94

|

|

V0

|

V0

|

|

storage temperature

|

/

|

℃

|

-20±2

|

<10

|

|

Quality guarantee period

|

/

|

Months

|

3

|

6

|

Hot Searches