- Product Details

- {{item.text}}

Quick Details

-

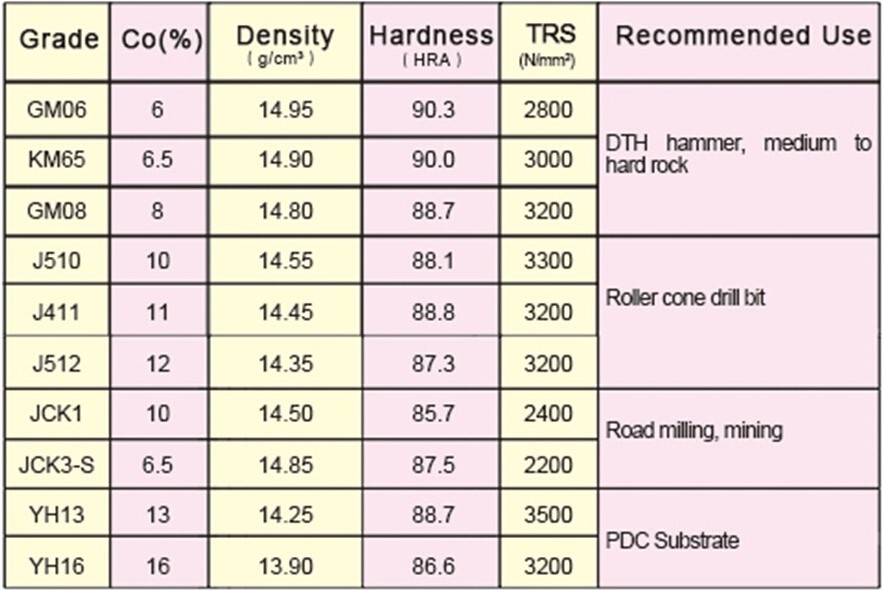

Chemical Composition:

-

WC+Co

-

ISO code grade:

-

K05/K10/K20/K30/K40

-

Particle/Grain Size:

-

Fine/Middle

-

Cobalt Content:

-

6.0Wt%/8.0Wt%/10.0Wt%/11.0Wt%/12.0Wt%

-

Density:

-

13.90-14.90

-

HRA:

-

86.5-90.3

-

TRS:

-

2200-3500

-

Surface:

-

Blanks Unground/ground/Polished

-

Certificate:

-

TUV

Quick Details

-

Type:

-

Power Tool Parts

-

Place of Origin:

-

Shandong, China

-

Material::

-

Tungsten carbide

-

Chemical Composition:

-

WC+Co

-

ISO code grade:

-

K05/K10/K20/K30/K40

-

Particle/Grain Size:

-

Fine/Middle

-

Cobalt Content:

-

6.0Wt%/8.0Wt%/10.0Wt%/11.0Wt%/12.0Wt%

-

Density:

-

13.90-14.90

-

HRA:

-

86.5-90.3

-

TRS:

-

2200-3500

-

Surface:

-

Blanks Unground/ground/Polished

-

Certificate:

-

TUV

1. Grade: K10,K20,K30,K40.

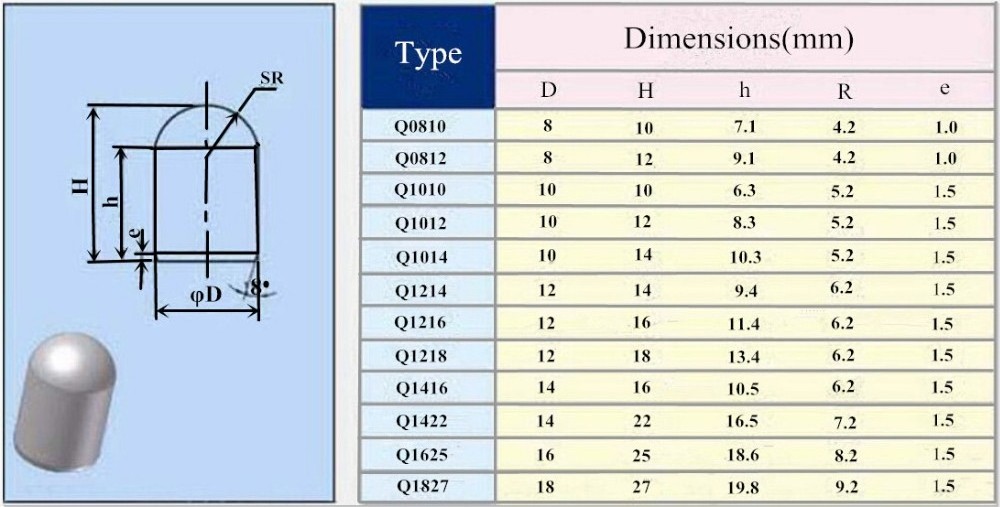

2. Model: Q0810,Q0812,Q1010.Q1012,Q1014,Q1214,Q1216,Q1218,Q1416,Q1422,Q1625,Q1827

3. Standard:ISO.

4. Certification: TUV.

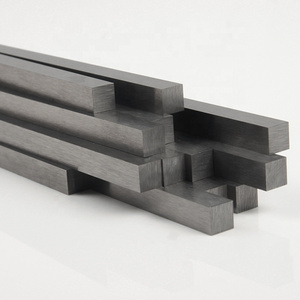

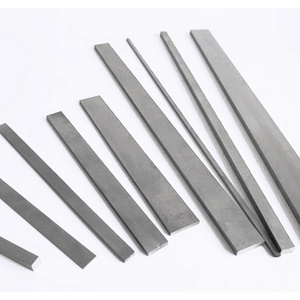

Other main products you might be interested in;

Packing Details : Carton and plywood case are suitable for internationl delivery(Air and sea transportation).

Delivery Details : Generally it is 3-5 days if the tungsten carbide button studs are in stock. or it is 15-30 days if the tungsten carbide button are not in stock, it is according to quantity.

Q: Are you trading company or manufacturer ?

A: We are the fourth largest tungsten carbide factory with more than 40 years production experience.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the tungsten carbide button studs are in stock. or it is 15-30 days if the tungsten carbide button are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the carbide mining tip sample for free charge,the cost of freight base on your quantity.

Q: Are solid tungsten carbide rods High Quality?

A: Yes,we have been in tungsten carbide field more than 40 years,R&D department,well-known China and USA experts specialize in researching novel tungsten carbide workmanship.