- Product Details

- {{item.text}}

Quick Details

-

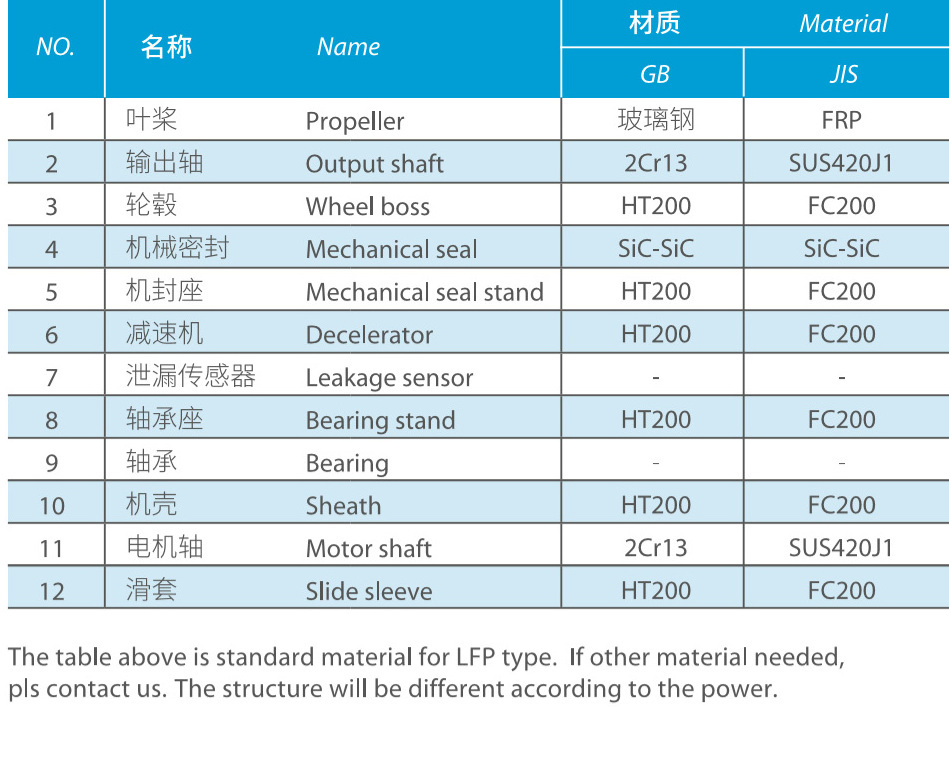

Productivity:

-

based on different model

-

Weight (KG):

-

100 kg

-

Power:

-

2.2~7.5kW

-

Diameter of propeller:

-

1100~2500mm

-

rpm of propeller:

-

34~63rpm

-

Thrust:

-

1100~4280N

-

Material:

-

FRP/ cast iron

-

Weight:

-

172~330kg

-

Rated current:

-

4.9-15.5 A

-

Voltage:

-

380/400/415/440/460 V

Quick Details

-

Core Components:

-

blade

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GSD

-

Productivity:

-

based on different model

-

Weight (KG):

-

100 kg

-

Power:

-

2.2~7.5kW

-

Diameter of propeller:

-

1100~2500mm

-

rpm of propeller:

-

34~63rpm

-

Thrust:

-

1100~4280N

-

Material:

-

FRP/ cast iron

-

Weight:

-

172~330kg

-

Rated current:

-

4.9-15.5 A

-

Voltage:

-

380/400/415/440/460 V

Application

Low-speed flow propeller extensively used for the oxidizing flow propelling and agitation in various types of biochemical tanks during the water treatment process, also can be used for river frost protection and, landscape water circulation etc.

Features

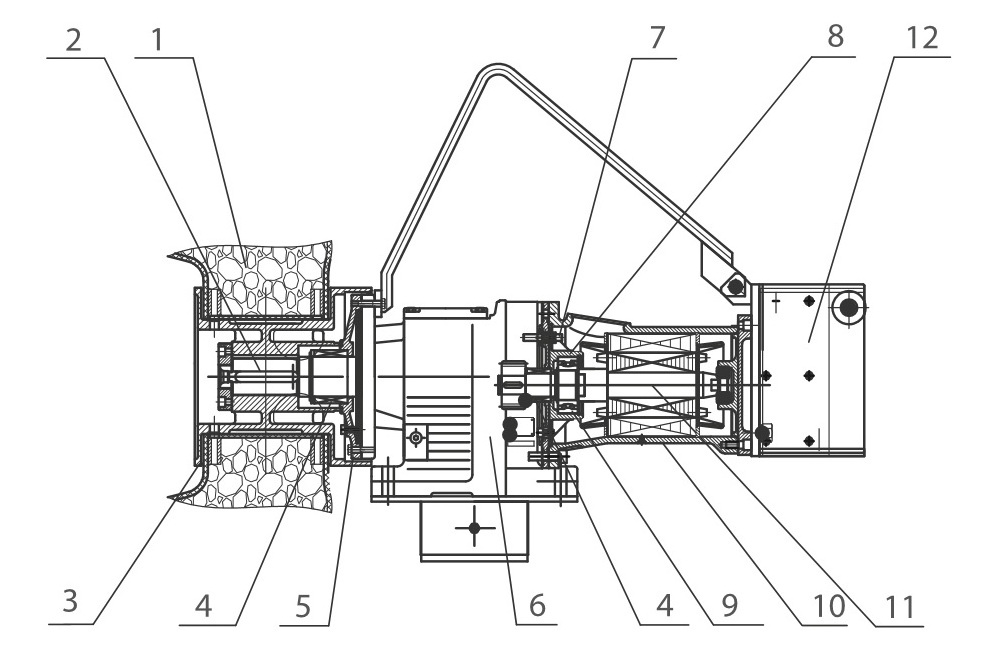

1. The international well-known high-quality bearings have longer service life, which are maintenance free.

2. The unique sealing design for the cables removes the hiddendanger of water leakage for the cables.

3. The shaft of the motor employs the stainless steel, and therotors are inspected with the use of dynamic balancing, leading to smooth rotation.

4. The in-built leakage sensor and the alarming device for the over-temperature protection for the windings of the stator.

5. The vanes of the low-speed flow propeller are made of FRP, which are sweptback shape, have the selfcleaning function, the smooth and streamlined propeller surface distributes the propelling power equally.

6. On the low-speed flow propeller, all the tightening pieces which will contact media employ the stainless-steel material;The decelerator employs helical gear speed reducer with high safty coefficient.

Conditions of usage

1. The highest temperature of the media shall not exceed 40℃

2. The pH value of the media: 5~9

3. The density of the media shall not exceed 1150kg/m3

4. The depth of submersion shall not exceed 20m

5. The electric power supply: 380V, 50Hz

6. The motor: F/H class insulation and in accordance with IP68,

7. continuous operating in 24hr

Construction

Performance parameters

Installation mode and dimentions

1. The supporting frame and the lower support shall be fixed onto the pond wall and the pond bottom with the use of expansion bolts or chemical anchors. For the big diameter impellers and the big power mixers the best choice is to pre-embed.

2. While placing an order by customer. Please supply the pond depth H and the drawing of the pond shape so as to determine the dimensions of the guide rod and the number of the supporting frames.

3. A multiple of mixers with the same installation system can share one lifting system.

4. The installation systems may employ the material of stainless steel or carbon steel for the selection of the corrosion-resisting properties.

Installation dimensions

Arrange sketch map

The installation and positioning of the submersible mixers will produce a great impact on the effect of mixing. In order to obtain the perfect operating result, it is suggested that the advice of the specialized designers shall be followed and full consideration given to the shape of the pond, position of the water inlet and outlet, the vortex resulting from the outflow from the mixer onto the structures and some other conditions. Every effort shall be made to reduce the short-circuit circulation and the occurrence of dead corners and avoid the dashing of the flow against the pond wall for lowering the flow velocity. Making reference to the arranging sketch map below will help you to make a reasonable selection of the mixers and their installation modes.

Related products (you may be interested in)

| CP submersible pump | AR submersible aerator | MA submersible mixer |

| MH hyperboloid mixer | GRB roots blower | RSD disc diffuser |