- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.08-0.12Mpa

-

Density (kg/m³ ):

-

128

-

Length:

-

1000-10000mm

-

Working Temperature:

-

1000-1400℃

-

Fiber Diameter:

-

2.2μm

-

Shrinkage (1800 ℉, 3h):

-

-4.0

-

Thermal Conductivity:

-

0.034w/mk

-

Model Number:

-

305

-

Brand Name:

-

chaochen

-

Place of Origin:

-

Hebei, China

-

foundcation:

-

fireproof.waterproof

Quick Details

-

Thickness:

-

20-50mm

-

Width:

-

600.1200mm

-

Chemical Composition:

-

Al2O3, SiO2, ZrO2

-

Ultimate Strength (≥ MPa):

-

0.08-0.12Mpa

-

Density (kg/m³ ):

-

128

-

Length:

-

1000-10000mm

-

Working Temperature:

-

1000-1400℃

-

Fiber Diameter:

-

2.2μm

-

Shrinkage (1800 ℉, 3h):

-

-4.0

-

Thermal Conductivity:

-

0.034w/mk

-

Model Number:

-

305

-

Brand Name:

-

chaochen

-

Place of Origin:

-

Hebei, China

-

foundcation:

-

fireproof.waterproof

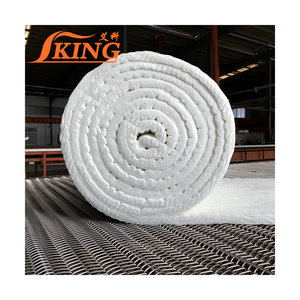

Introduction

Ceramic fiber blanket from ceramic fiber wool, natural refractory raw material, and a small amount of organic binder, and adopting the completely automated control continuous production technology. Because of the high fiber content, it has the characteristics of high temperature, light weight, and heat shock resistance, which is one of the important guarantee factors of kiln energy-saving, cost-reducing, high quality and yield, can be widely used in industrial kiln heat insulation layer.

Characteristics

Low thermal capacity, low heat conductivity

Non-brittle material, good elasticity

Good wind erosion resistance performance, long service life

Excellent thermal stability and thermal shock resistance

Good Sound-absorbing performance

Rigid, self-supporting plate

Good anti-strip performance

Easy molding and cutting

Applications

- Iron and steel industry: expansion joints, the back lining heat insulation, heat insulation sheet and molds

- nonferrous industry : tundish and laund shield, used for pouring copper or copper-containing alloy

- Ceramic industry: lightweight structure of kiln car , kiln heat surface lining body, separation and f ire shield of each kiln temperature zone

- Glass industry: molten pool backing insulation, nozzle

- Kiln construction: hot surface refractory material (instead of blanket), heavy refractory material backing and expansion joint

- Light industry: Lining of industrial and domestic boiler furnace

- Petrochemical industry: hot surface material of high temperature kiln lining

- Craft glass and other deep-processing shaped mold